Three Shaft Air Jet (Water) Loom

A technology of weaving shafts and looms, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as difficulty in satisfying aesthetics and comfort, restrictions on the use of shading cloths, and insufficient thickness of shading cloths, and achieve bright and rich colors, simple structure, Avoid the effects of waves and unevenness on the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

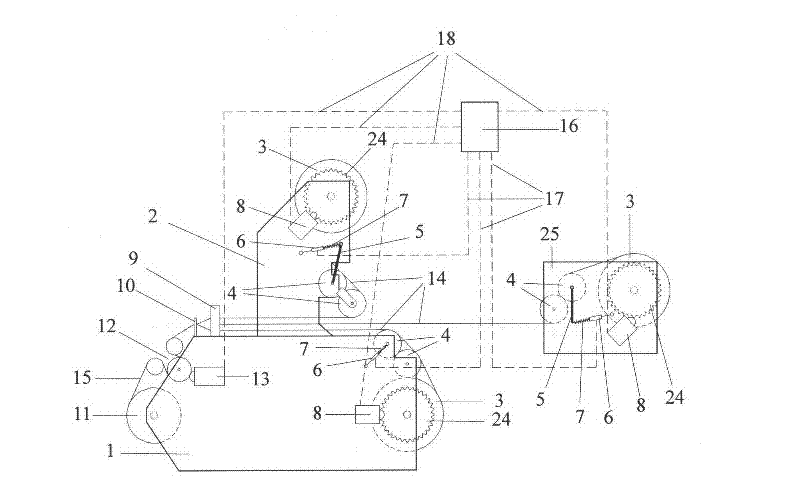

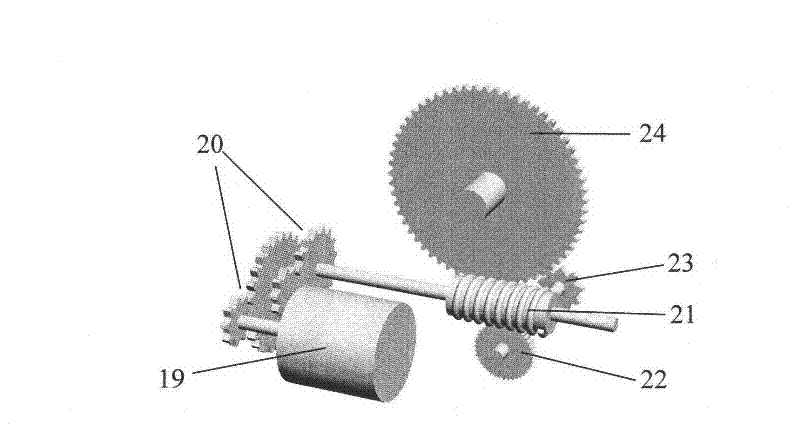

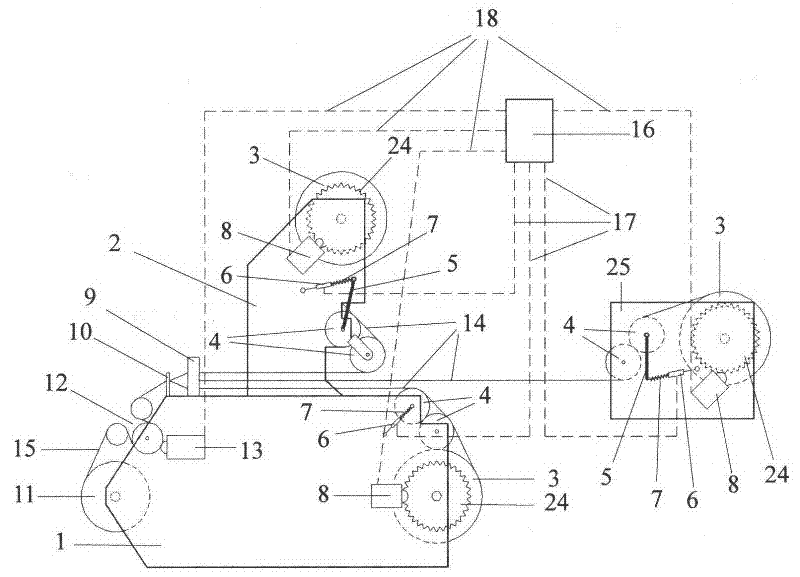

[0016] Such as figure 1 As shown, the three-shaft air-jet (water) loom includes a frame 1, a wall panel 2, a warp beam 3, a roller bar 4, a tension conducting arm 5, a tension sensor 6, a tension spring 7, an electronic let-off servo Device 8, opening mechanism 9, steel reed 10, cloth winding shaft 11, winding roller pull bar 12, electronic winding servo device 13, warp thread 14, cloth surface 15, main control CPU 16, tension signal transmission line 17, compensation signal transmission line 18, F wall panels 25. The three-beam air-jet (water) loom has three sets of weaving-beam systems, each of which is equipped with warp beam 3, upper and lower roller bars 4, tension conducting arm 5, tension sensor 6, tension spring 7, electronic warp let-off servo device 8. One of the weaving beam systems is installed below one side of the frame 1, the warp beam 3 and the upper and lower roller bars 4 are respectively installed in the shaft holes of the matching frame 1, and the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com