Double membrane pump suction washing method and washing machine

A washing method and pump-suction technology, applied in the field of washing, can solve the problems of inability to meet the strength requirements, the capsule has dead corners, the overall structure is complex, etc., and achieve the effect of a simple and novel overall structure, uniform pressure without dead ends, and comprehensive washing functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

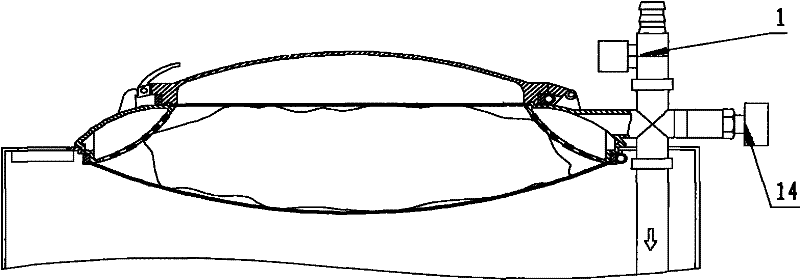

[0017] The double-membrane pump-suction washing method of the present invention is to form a closed washing chamber between the washing chamber 15, the upper adhesive film 16 and the lower adhesive film 11, and the upper and lower adhesive films are driven by the positive and negative pressure formed by the inlet and outlet. It expands and contracts, thereby simulating human hands squeezing and kneading clothes to complete the washing work.

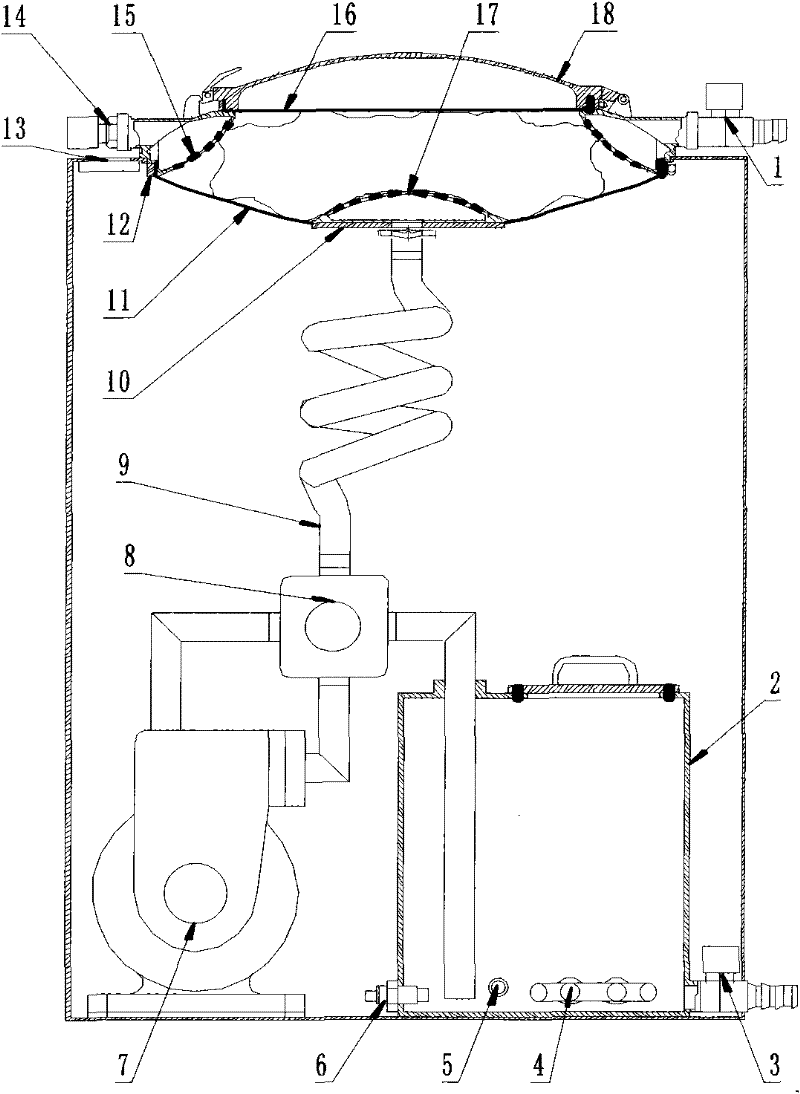

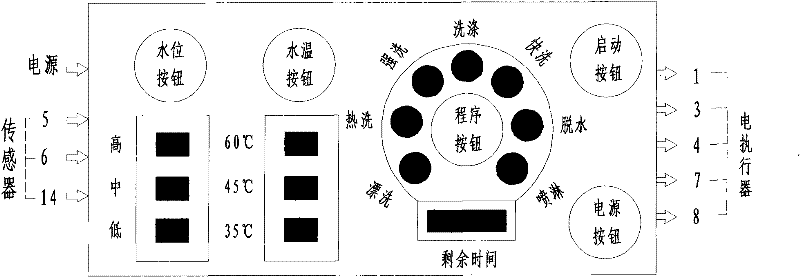

[0018] Such as figure 1 As shown, the double-membrane pump-suction washing machine of the present invention mainly consists of a washing chamber 15, a water tank 2, a self-priming pump 7, an electromagnetic reversing valve 8 and a microcomputer control panel 13 arranged in the washing machine housing. Washing chamber 15 is positioned at the top of washing machine housing, adopts plastic material to make, and washing chamber 15 cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com