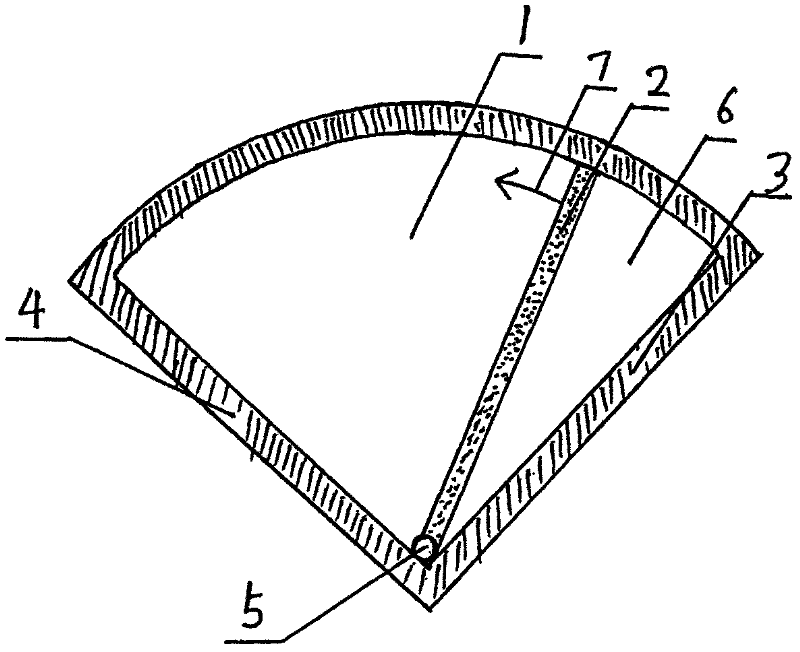

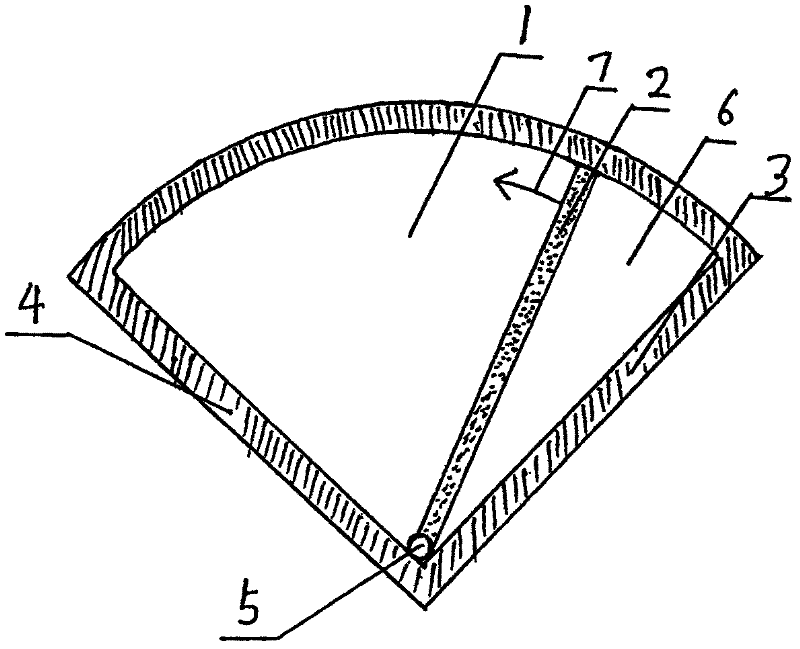

Internal combustion engine sector cylinder

An internal combustion engine and fan-shaped technology, which is applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of high internal consumption power, low efficiency of cylinder work, and many moving parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In the invention, a leaf-shaped shutter is installed in the fan-shaped cylinder, the shutter shaft is installed at the intersection of the two ends of the cylinder, and the moving parts only have the shutter when doing work, so the structure is very simple. Since only the valve is in contact with the cylinder, the frictional resistance is very small when the work is done, the moving parts are few when the work is done, and the mass of the moving parts is also reduced, which improves the efficiency of the internal combustion engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com