Liquefied gas stove heat storage, ventilation, smoke cleaning and energy saving

A technology of liquefied gas and energy-saving device, applied in the field of cooking appliances, can solve the problems of limited energy-saving effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

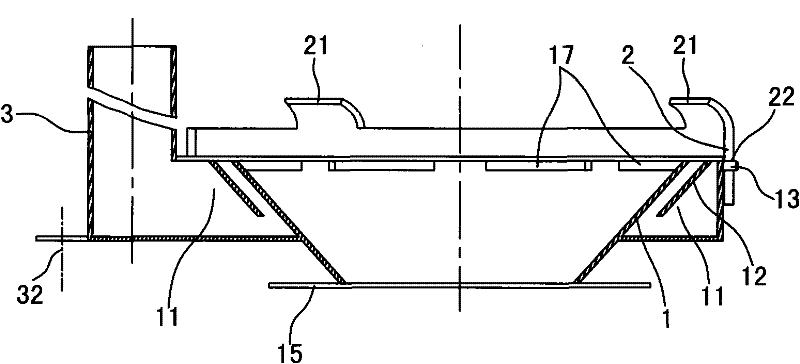

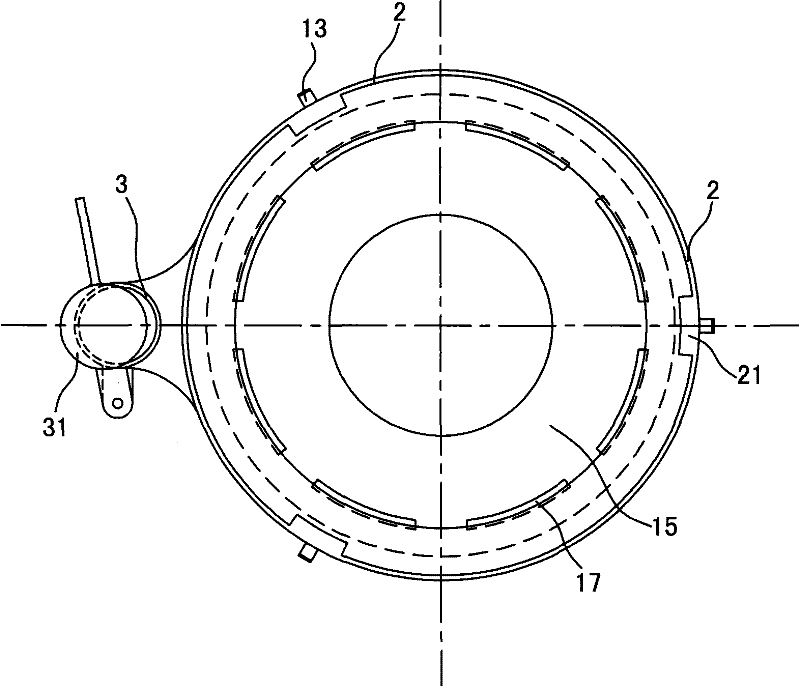

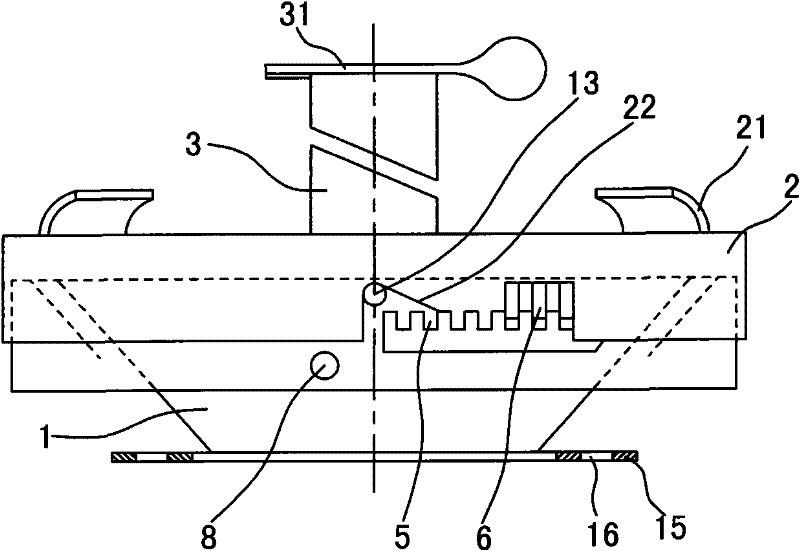

[0013] The invention relates to a liquefied gas stove heat storage, ventilation and smoke cleaning energy saver, such as Figure 1-Figure 6 As shown, it includes a heat storage tray body, the heat storage tray body has a hollow cavity, and a heat insulation device is arranged in the hollow cavity. Connected to the hollow cavity 11, the side of the heat storage tray body 1 is equipped with a drawing pipe 3, and the hole of the drawing pipe communicates with the hollow cavity 11 of the heat storage tray body. This technical solution mainly includes a circular heat storage tray 1, the inner wall of the heat storage tray is similar to the inclined curved surface of the bottom of a spherical pot or the inclined straight surface of a conical shape, and the remaining outer walls can be cylindrical to form a hollow cavity 11, the hollow cavity 11 A heat insulation device is arranged inside, and there is a hollow cavity in the heat storage plate, so there is an air exchange port 17 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com