Integrated measurement method for friction parameters and moment of inertia of servo turntable lugre model

A technology of moment of inertia and servo turntable, applied in the field of measurement and control, can solve problems such as failure to solve friction dynamic parameters, failure to analyze friction nonlinear characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

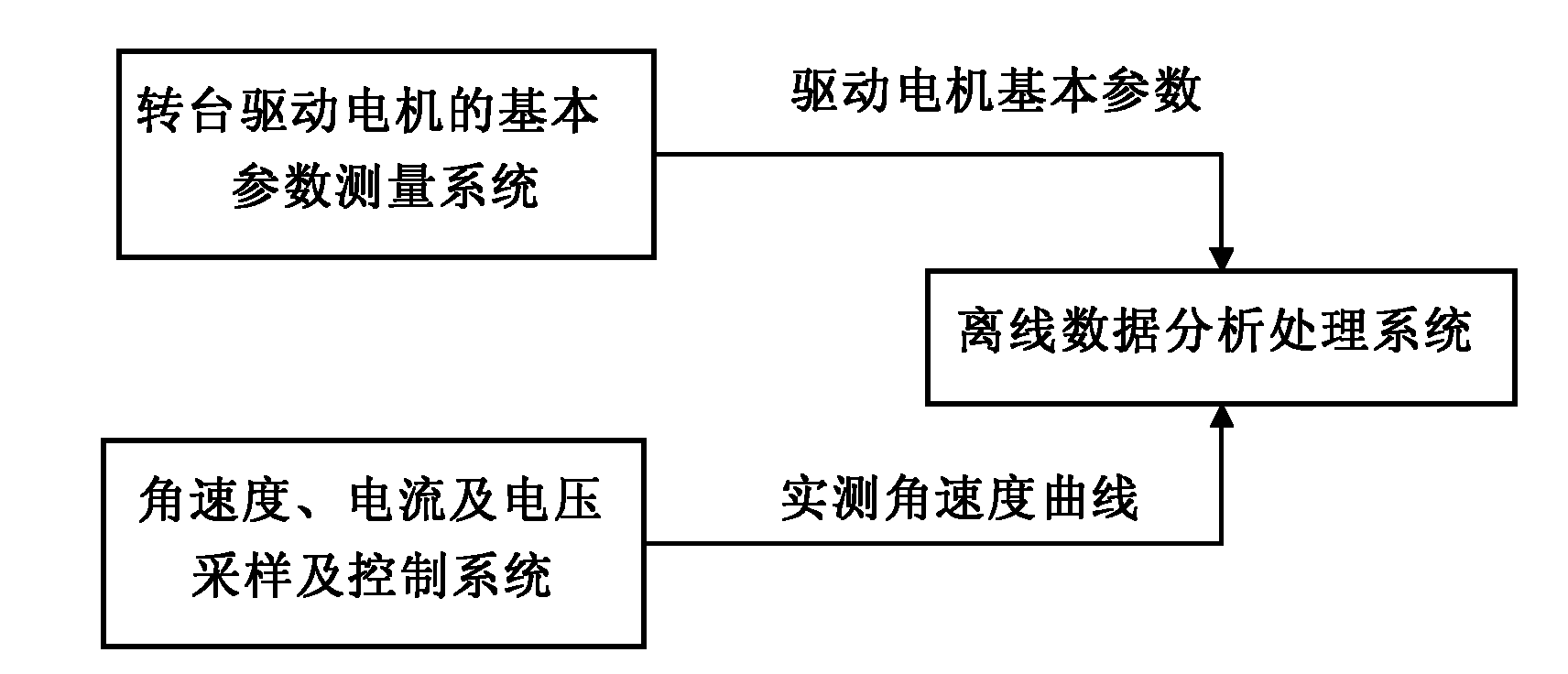

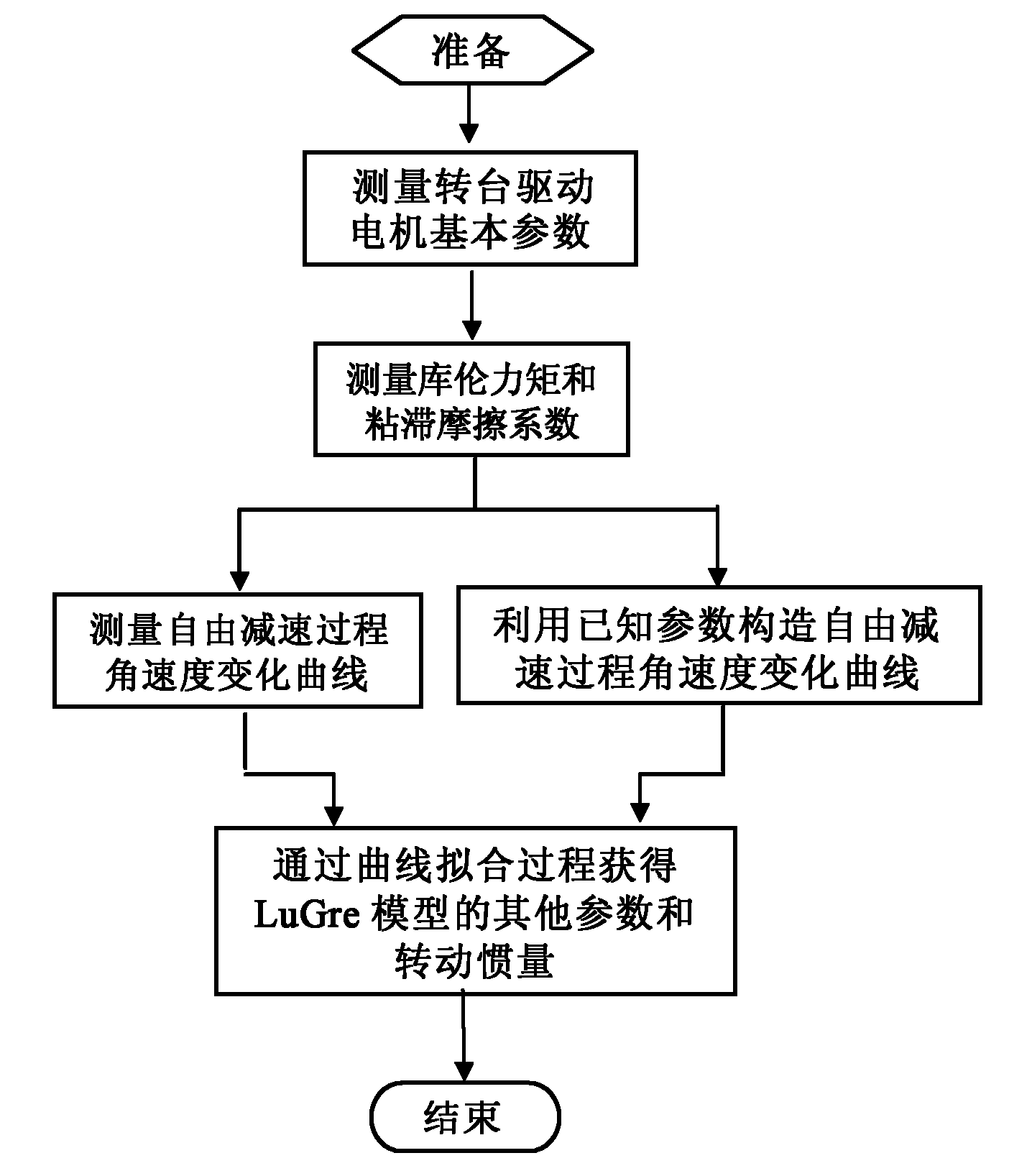

Method used

Image

Examples

Embodiment Construction

[0032] Examples of the present invention are described below. But following embodiment only limits to explain the present invention, and protection scope of the present invention should comprise the whole content of claim, and promptly can realize the whole content of claim of the present invention to those skilled in the art through following embodiment.

[0033] The present invention does not need to install a torque sensor, and does not damage the integrity of the turntable; in the measurement process, only the driving current, the angular velocity of the turntable and other information are required, which is convenient to realize, and can accurately describe the complex dynamic and static characteristics of the friction process, and facilitates the adjustment of the turntable. Perform high-precision control.

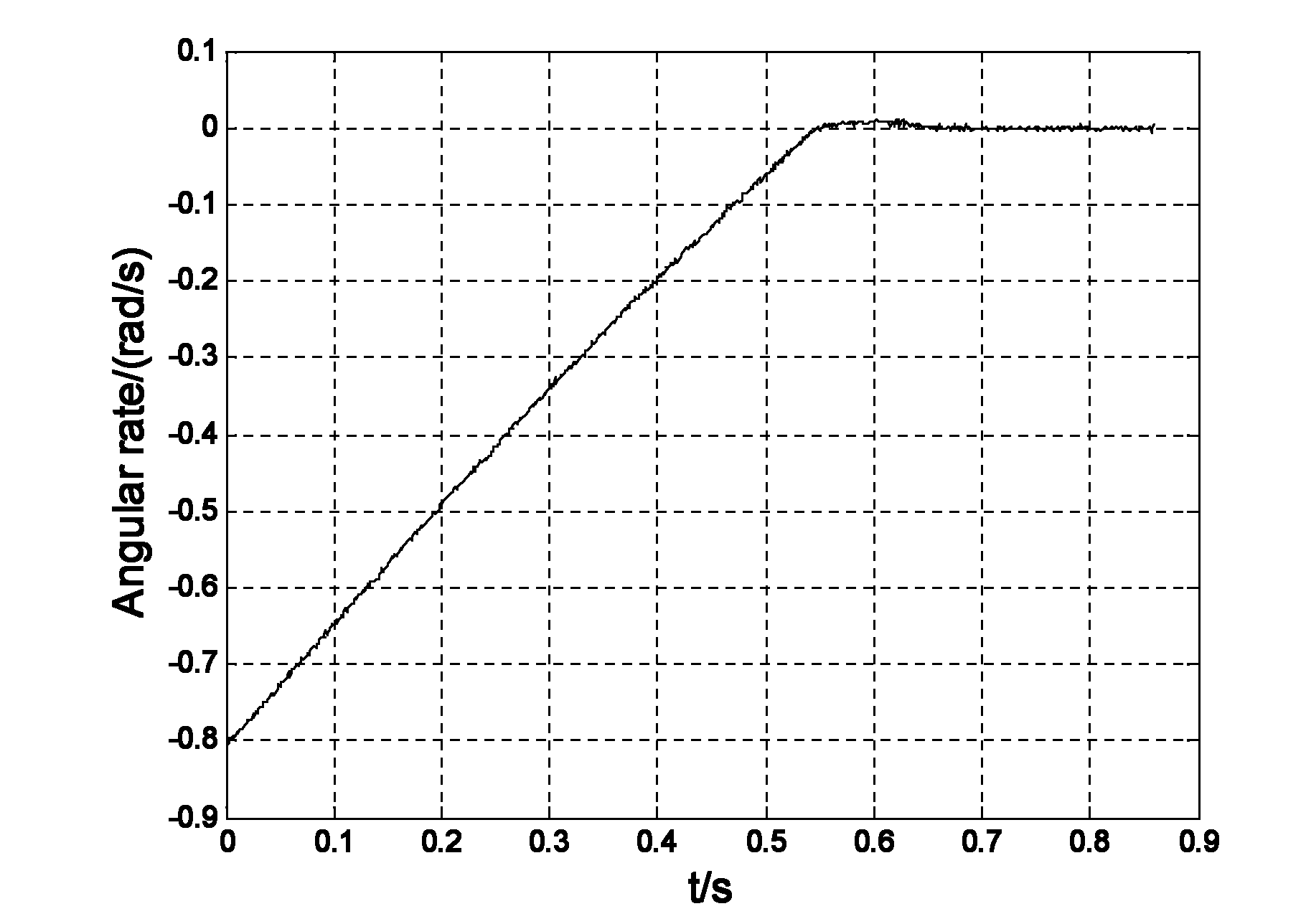

[0034] The zero-crossing phenomenon of the speed of the servo turntable in the free deceleration mentioned in the present invention means that the servo turntable is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com