Illumination Sorting Station for Small Defects of Solar Cells

A kind of solar cell, subtle technology, applied in the direction of optical testing flaws/defects, material analysis by optical means, material analysis, etc., can solve the problems of incomplete cell sorting, high missed detection rate, limited desktop board area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

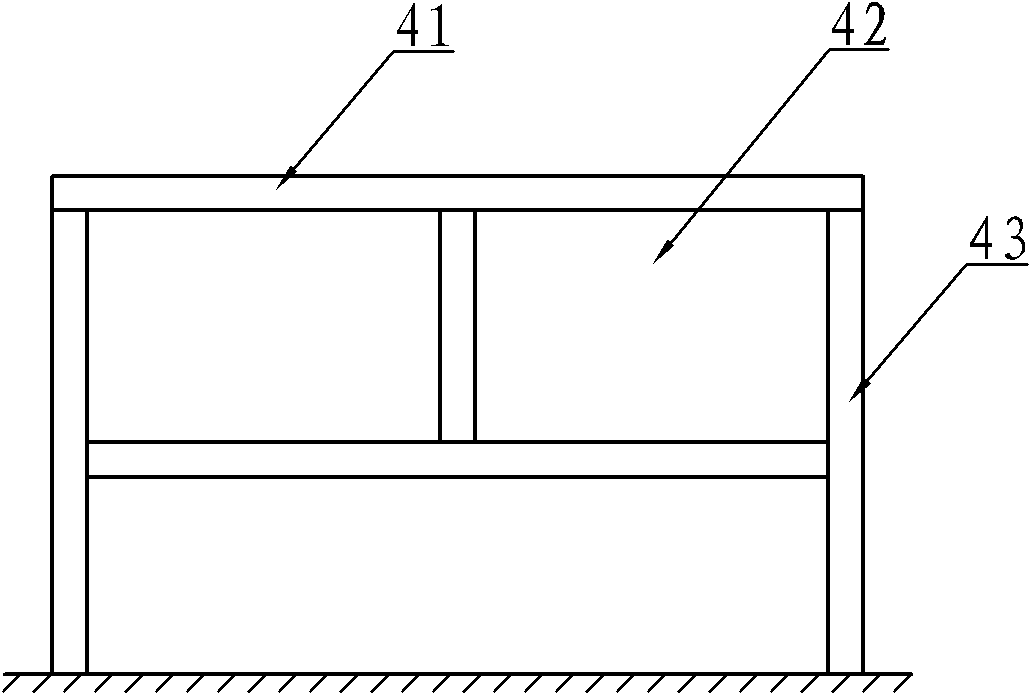

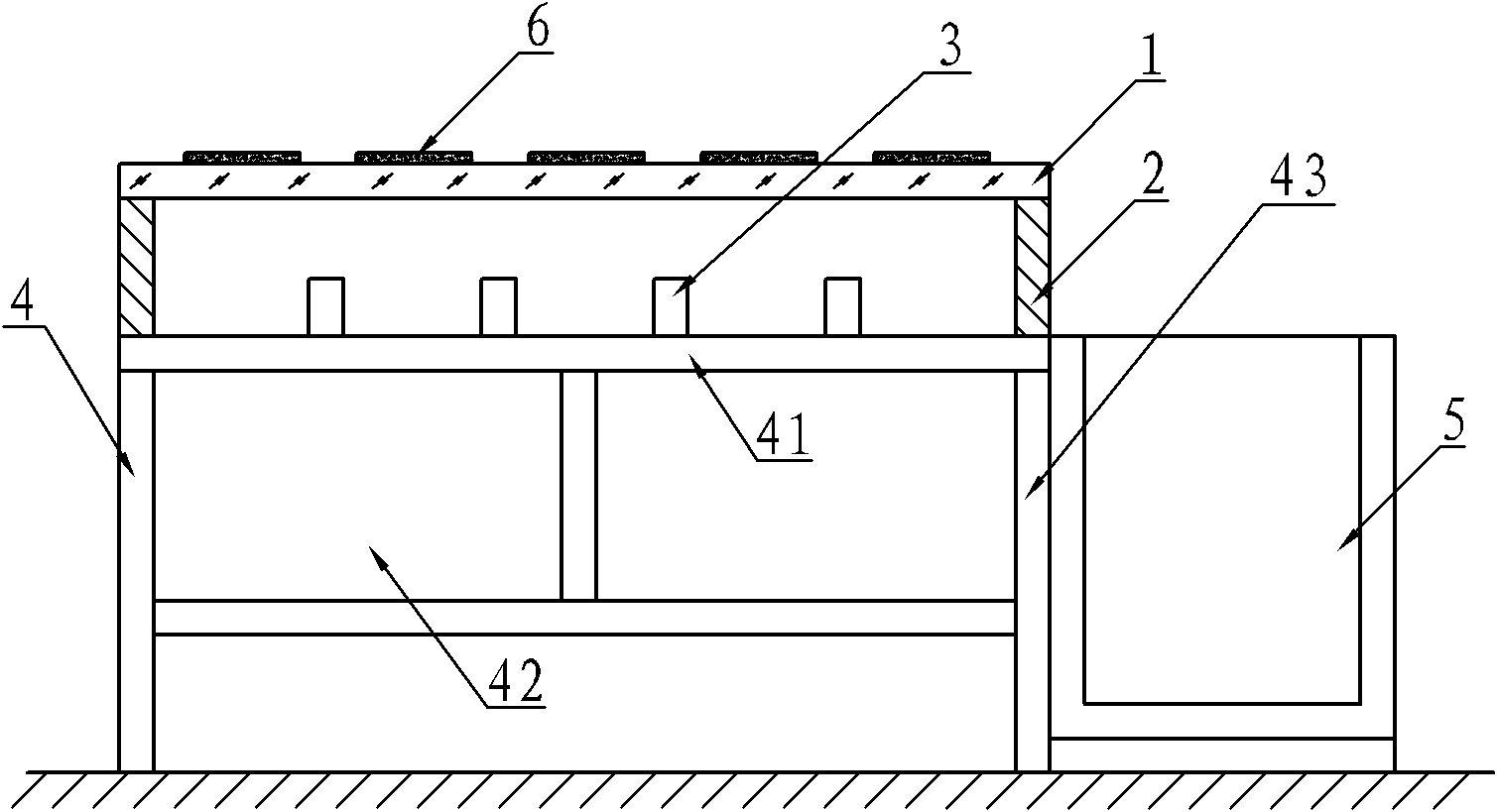

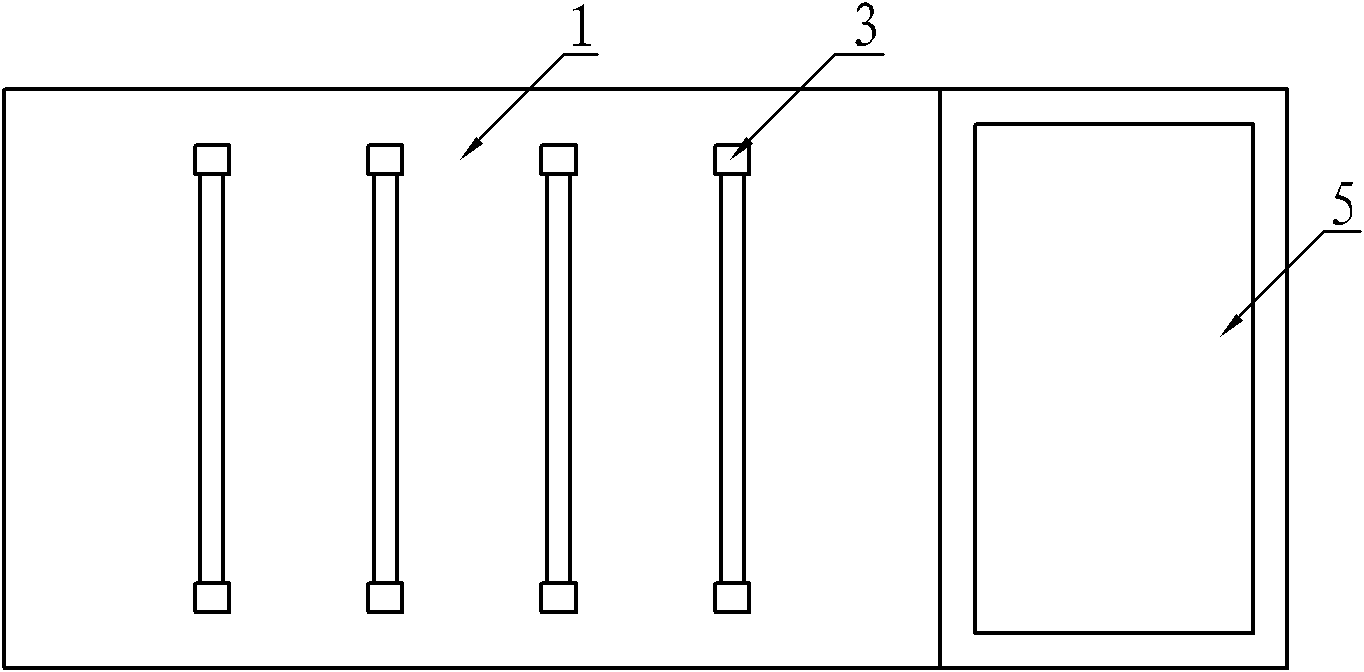

[0017] A sorting platform for light-based inspection of minor defects in solar cells, such as figure 2 , image 3 As shown, it includes a smooth transparent glass plate 1, a frame-shaped tray 2, a lighting lamp 3 and a desk table 4, and the desk table 4 is composed of a desktop board 41, a drawer 42 and a support frame 43, and the desktop board 41 is fixed on the support The top of frame 43, drawer 42 is positioned at the below of table top 41 and is fixed on support frame 43, and frame tray 2 is fixed on the table top 41 of desk table 4, and lighting lamp 3 is fixedly installed on the table top board of desk table 4 41, and is located in the frame tray 2, the smooth transparent glass plate 1 is placed on the top of the frame tray 2, and the right side of the desk 4 is provided with a defective product box 5, and the height of the defective product box 5 is higher than that of the smooth transparent glass. Board 1 is 5~20 centimetres, and two drawers 42 on the desk table 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com