Electrode structure and manufacturing method thereof

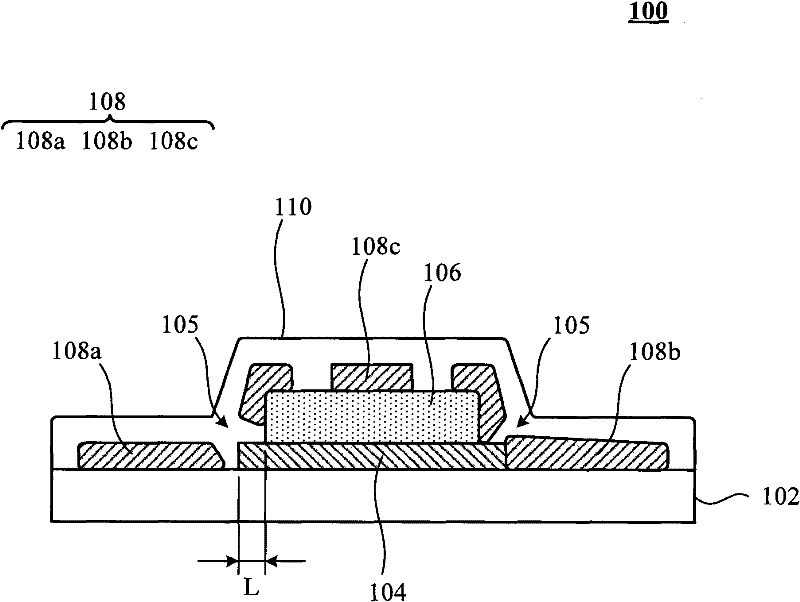

A technology of electrode structure and manufacturing method, applied in the direction of electrical digital data processing, instrument, data processing input/output process, etc., can solve the problem of increased contact resistance value, incomplete contact, and poor step coverage of transparent electrode layer 108 And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

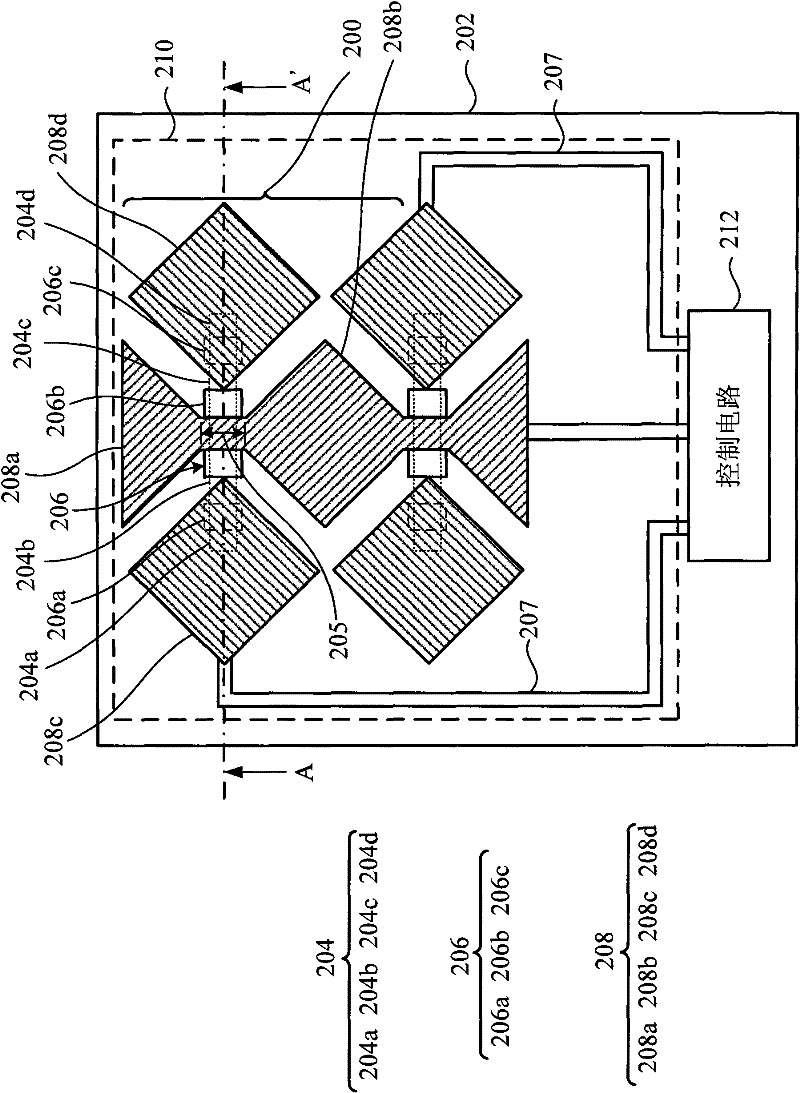

[0022] reference figure 2 , Which shows a schematic diagram of the wiring of the electrode structure in an embodiment of the present invention. The electrode structure 200 (such as Figure 3F (Shown) is suitable for capacitive touch panels. The electrode structure 200 mainly includes a substrate 202, an electrode bridge structure 204, a dielectric layer 206, a conductive pattern 208, and a passivation layer. 210. The electrode structure 200 is connected to a control circuit 212 through an electrode circuit 207. The control circuit 212 is used to process the sensing signal from the electrode structure 200. The electrode circuit 207 and the conductive pattern 208 are located in different areas on the substrate 202 . It should be noted that the above and the lower two electrode structures 200 are taken as examples here, but the present invention is also applicable to more than two electrode structures 200 to form a matrix electrode structure.

[0023] The electrode bridging struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com