An installation device for a vacuum processing system

An installation device and vacuum processing technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complex unloading mechanism, waste of manpower and material resources, affecting the process, saving manpower, avoiding pollution, installation/disassembly handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with the accompanying drawings.

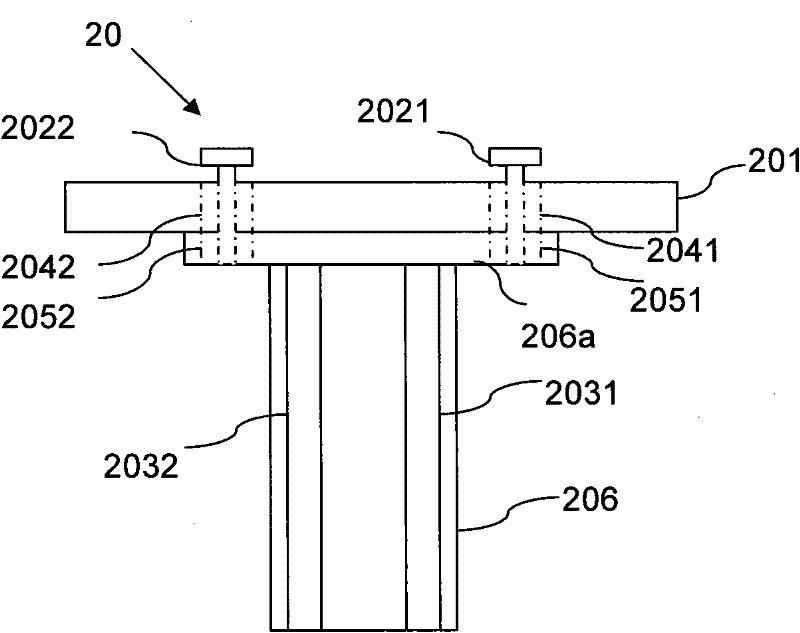

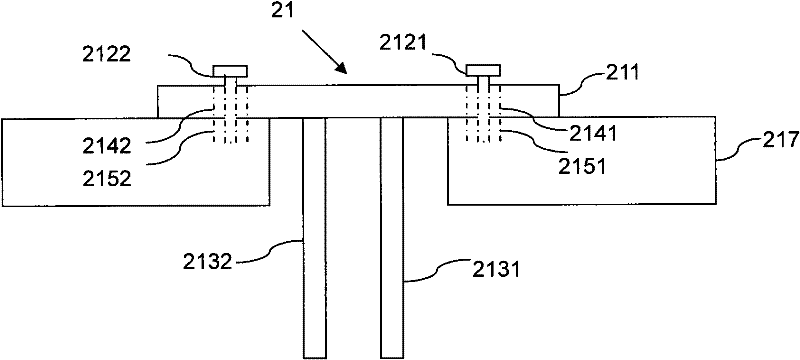

[0026] The first aspect of the present invention provides an installation device for a vacuum processing system, combined below Figure 2a~2c , the first invention of the present invention will be described according to a preferred embodiment of the present invention, wherein the vacuum processing system is typically a plasma etching machine.

[0027] Figure 2a It shows a structural schematic diagram of an installation device for a vacuum processing device according to a specific embodiment of the present invention, which includes:

[0028] A flat disc-shaped mounting plate 201 is disposed between an electrostatic chuck (not shown) and various components located below the electrostatic chuck. As we all know, the electrostatic chuck (Electrostatic Chuck) is also generally in the shape of a flat disc, which is closely arranged above the mounting plate 201 and fixed to the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com