Damping device for aero-engine thin-wall cartridge receiver part internal shape processing

A technology of aero-engine and vibration damping device, which is applied to metal processing mechanical parts, positioning devices, metal processing equipment, etc., can solve problems such as distortion, bending, shearing, and difficulty in parts processing, and improve stiffness and stability. , Easy installation/disassembly, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

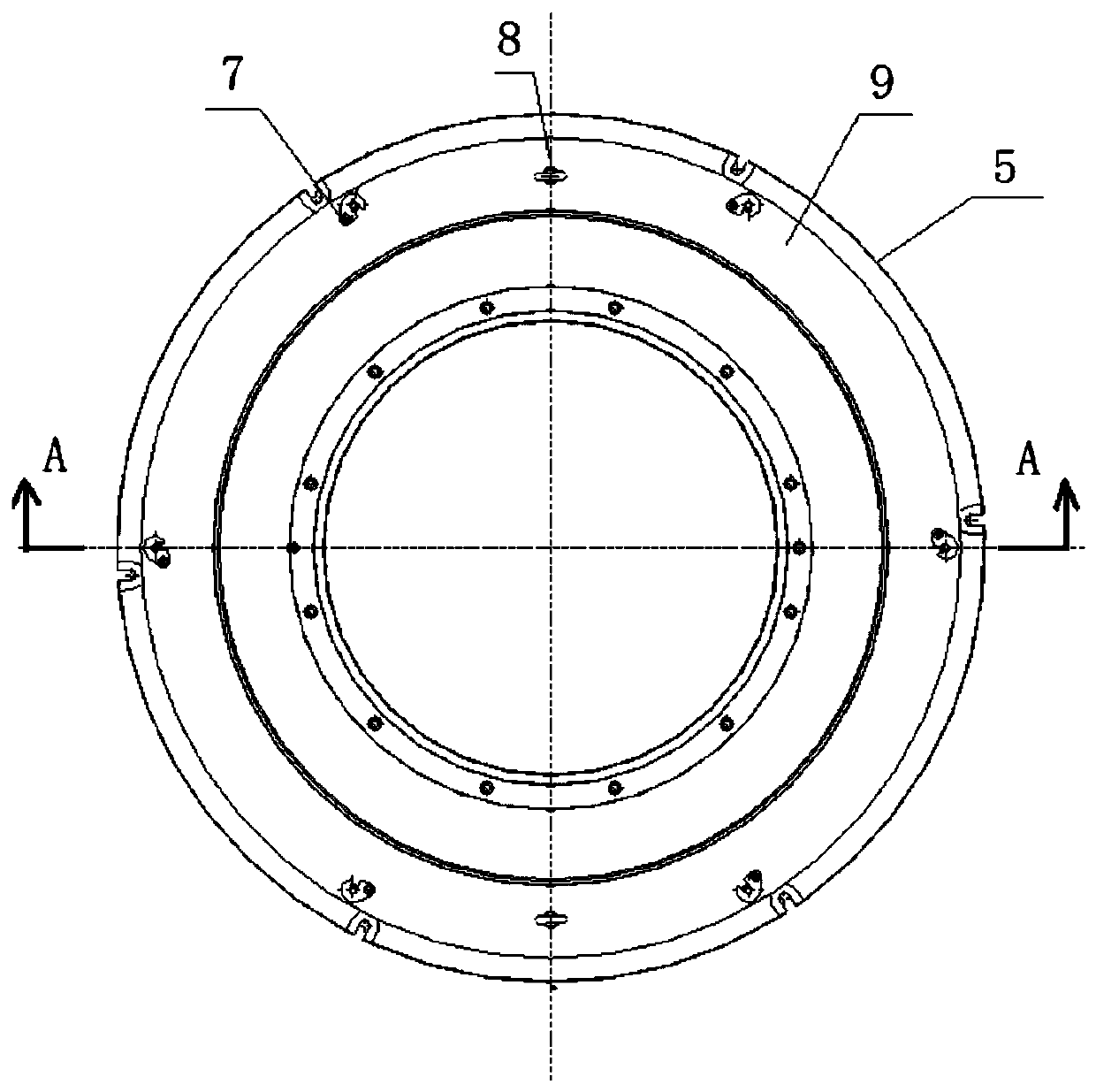

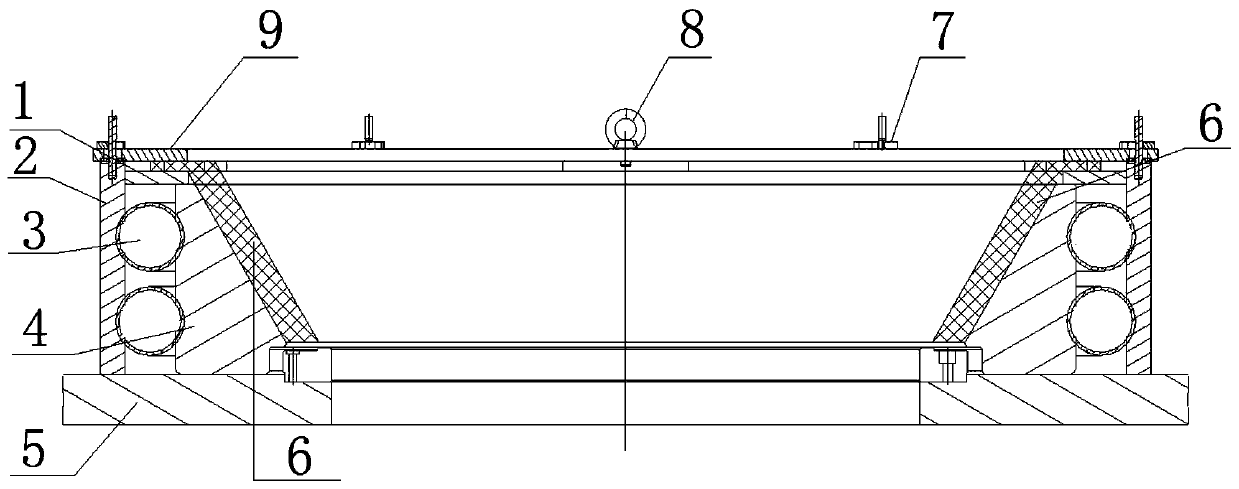

[0029] Such as figure 1 and figure 2 Shown:

[0030] A vibration damping device for processing the inner shape of thin-walled casing parts of an aero-engine, comprising a base 5, a pillar 2, a limiting pressure assembly 9 and a gas damper;

[0031] The pillar 2 is an annular tubular structure, the pillar 2 is arranged on the base 5, and the axis of the pillar 2 is perpendicular to the plane where the base 5 is located;

[0032] The limit pressure assembly 9 is detachably arranged on the top of the pillar 2;

[0033] The gas damper is arranged on the inner surface of the strut 2 .

[0034] When in use, the staff uses a spray gun to spray the damping and absorbing member 6 on the outer surface of the high-pressure turbine casing, then opens the limit pressure assembly 9, and installs the sprayed damping and absorbing member 6 casing in the shock absorbing device And carry out alignment, then install the limit pressure assembly 9 on the column, press and fix the parts in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com