Device for generatively producing three-dimensional objects with the aid of an insulated construction zone

A technology for three-dimensional objects and equipment, applied in the fields of processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of uneven mechanical properties of objects, uneven temperature, etc., and achieve the effect of improving the effective use area and reducing the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

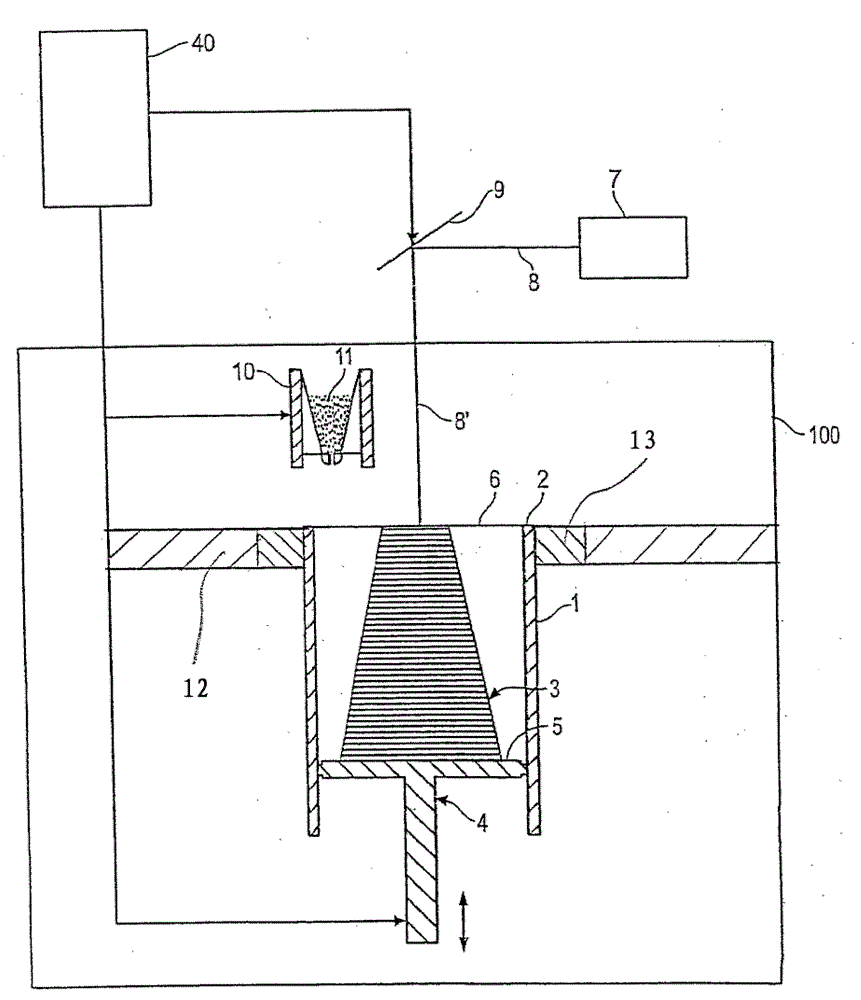

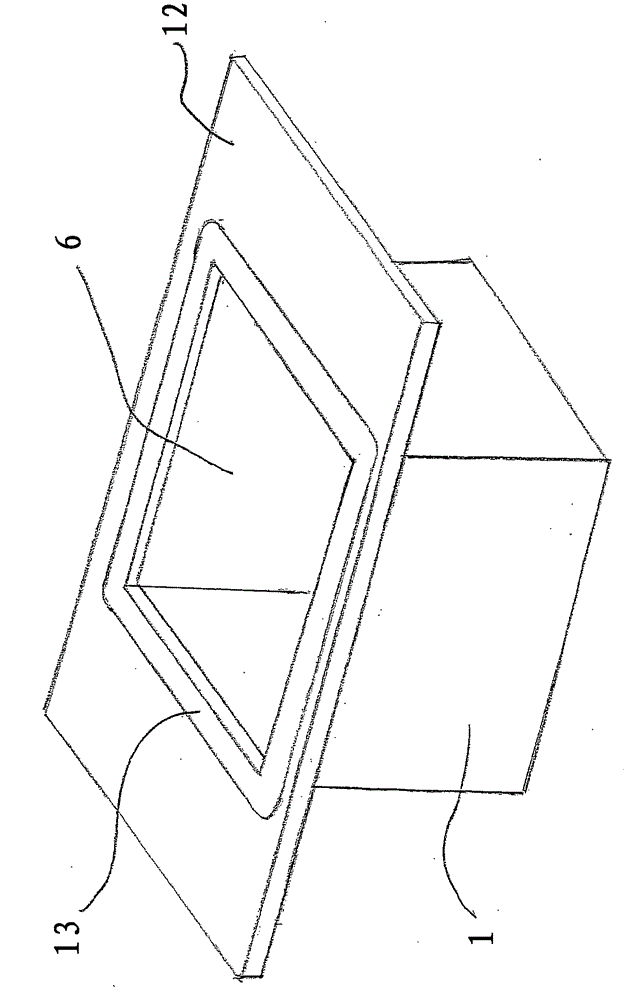

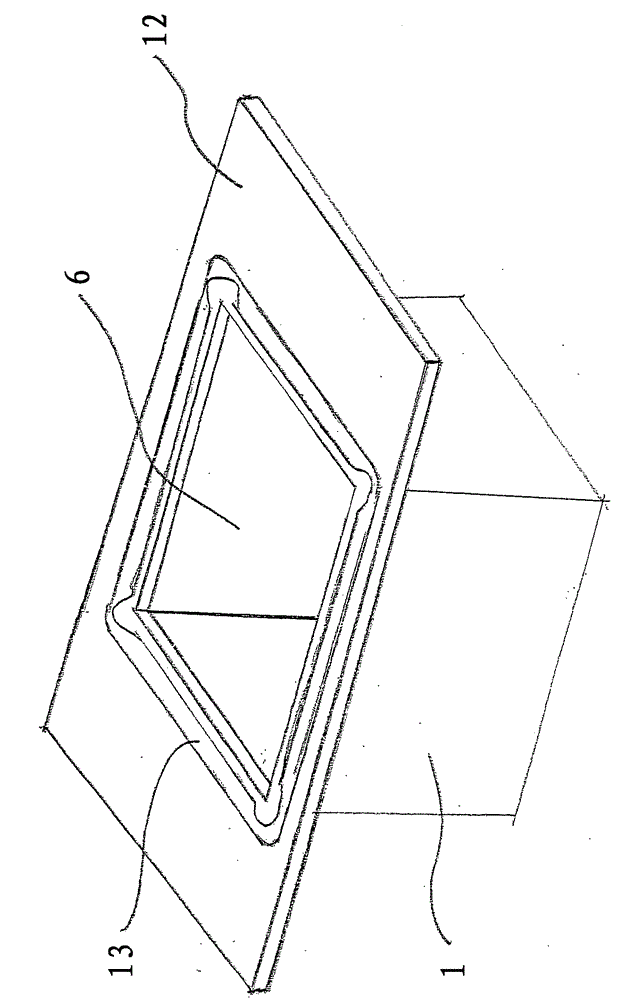

[0011] figure 1 A schematic diagram of a device for producing a three-dimensional object 3 according to a first exemplary embodiment of the invention is shown, which is designed as a laser sintering device by way of example.

[0012] The laser sintering device has a frame 1 with an upward opening, and the frame has a vertically movable support 5 located in the frame, and the support carries a three-dimensional object 3 to be manufactured. The frame 1 surrounds a construction area 6 with its upper section 2 . Preferably frame 1 and support 5 form an exchangeable frame which can be removed from the laser sintering device. The support 5 is connected to a lifting mechanism 4 which moves the support vertically at least below the plane of the building area 6 so that the upper side of each powder layer to be solidified lies in the plane of the building area 6 . The plane of the construction area here means the plane in which the upper edge of the upper section 2 lies.

[0013] Fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com