Printing units for printing on bottles or similar containers

A printing device, printing position technology, applied in the direction of printing, typewriter, etc., capable of solving the problems of printing ink not arriving, wrong quality, undesired staying on the elements of the printing device concerned, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

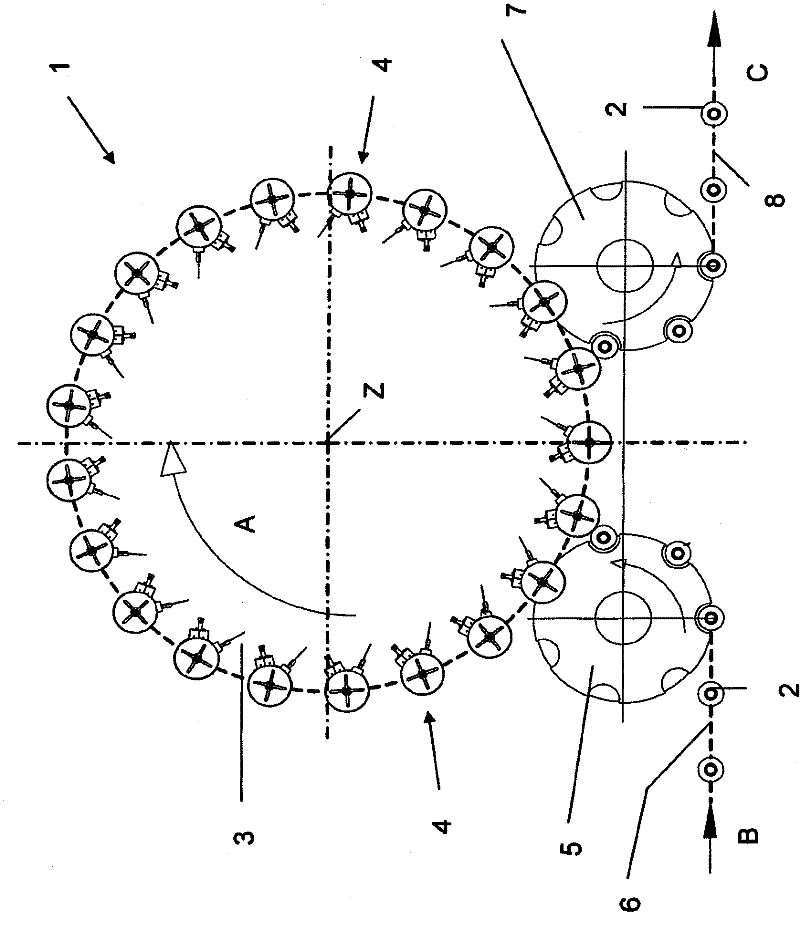

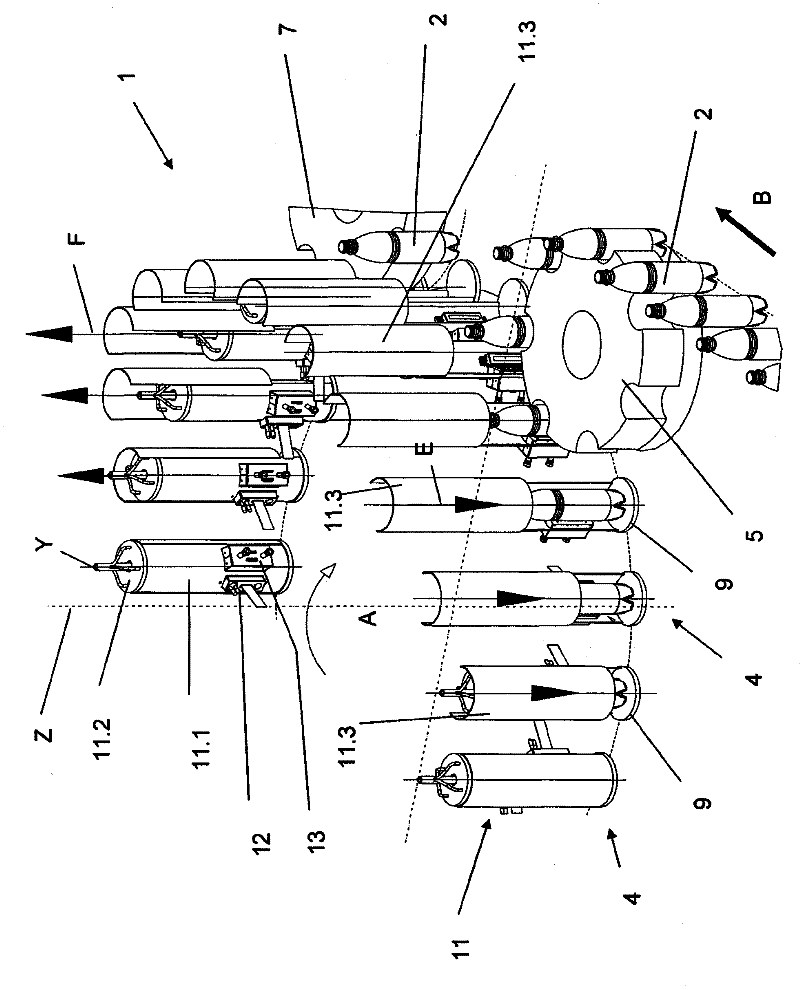

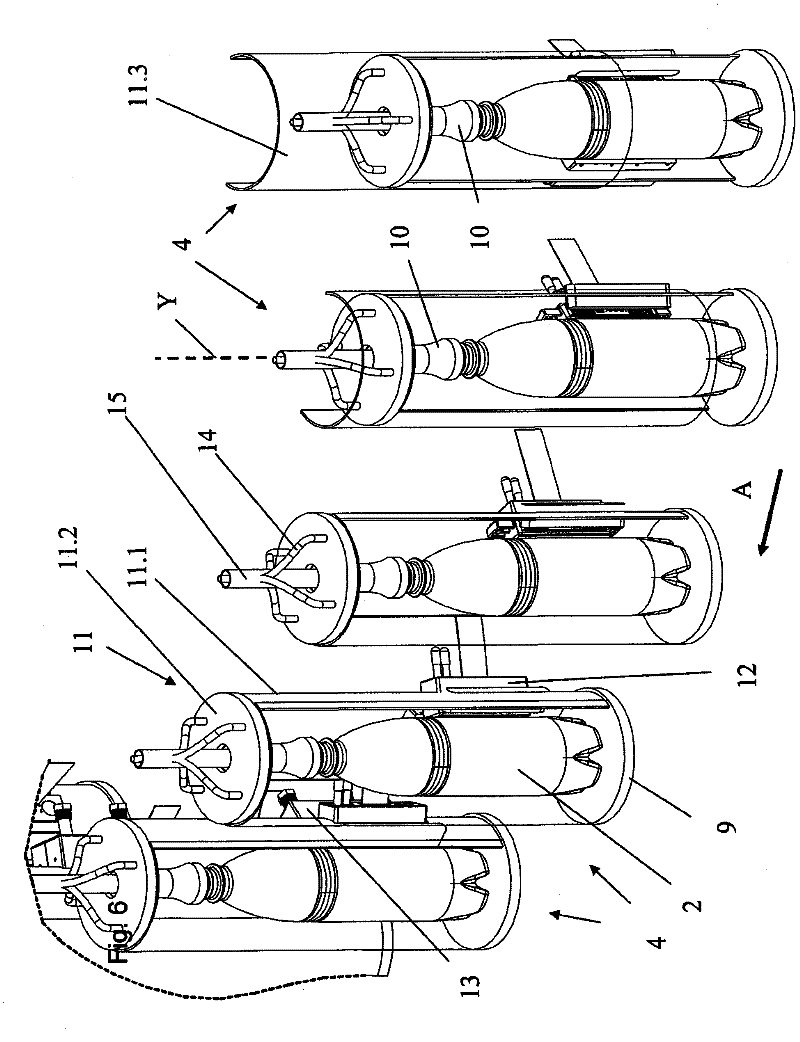

[0013] exist Figure 1-4 The printing unit, generally designated 1 , is used for the direct printing of containers, which in the depicted example are bottles, in particular PET bottles 2 .

[0014] The printing unit 1 comprises, inter alia, a printing wheel or runner 3 which can be driven in rotation about a vertical machine axis Z (arrow A) and which, on its periphery, runs around the machine at uniformly distributed angular distances The axis Z configures a plurality of processing or printing positions 4 .

[0015] The bottles 2 to be printed are fed to the container inlet of the printing unit 1 by means of an external conveyor 6, shown as an infeed star 5, the bottles 2 to be printed are upright, i.e. their bottle axes are directed vertically, and Following one another in the conveying direction B of the conveying device 6 , each bottle 2 reaches the printing station 4 via an infeed stand 5 . The already printed bottles 2 are respectively moved away from the printing stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com