Physical constant temperature seat and manufacturing method thereof

A constant temperature and physical technology, applied to chemical instruments and methods, chairs, other seating furniture, etc., can solve the problems of prolonging the use time of constant temperature and not being able to effectively maintain constant temperature, so as to improve work and study efficiency, reduce prostatitis, The effect of eliminating fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation of the physical constant temperature seat of the present invention will be further described below in conjunction with the accompanying drawings.

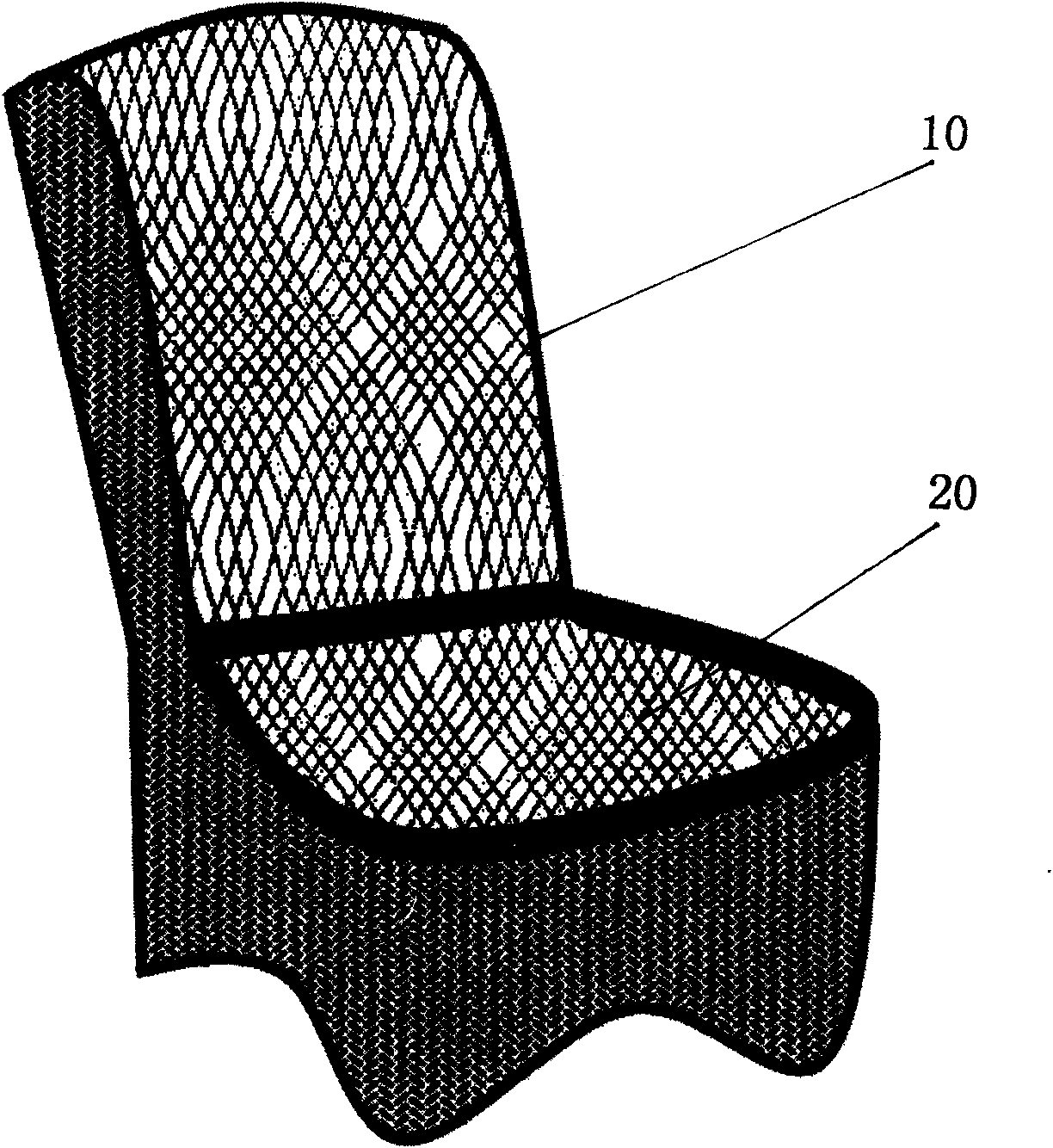

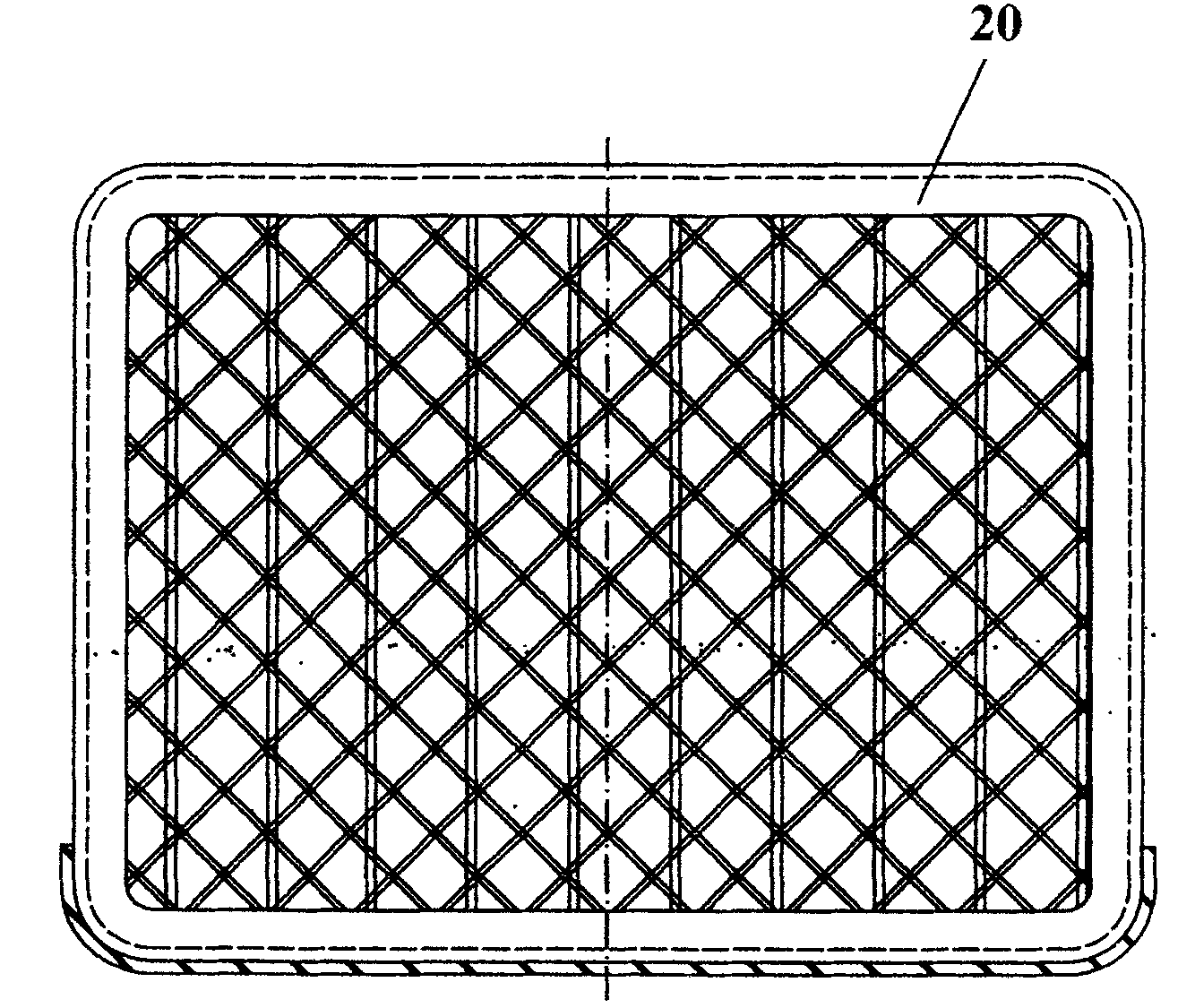

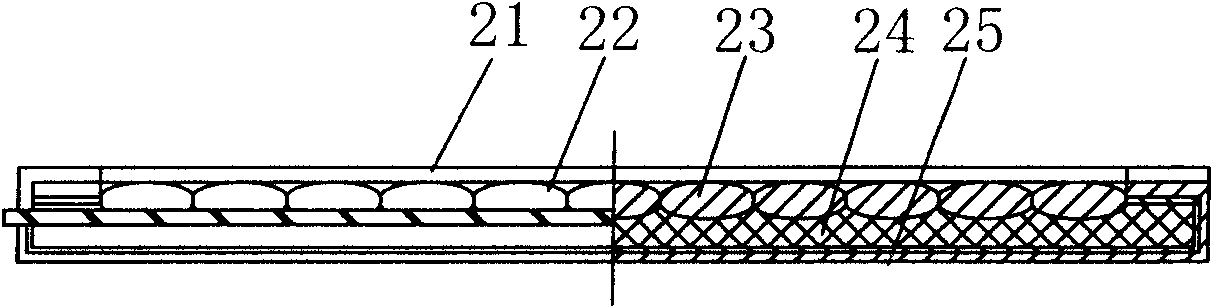

[0036] Such as Figure 1-Figure 8 As shown, the physical constant temperature seat of the present invention is made of a seat and a physical constant temperature chair pad, and the physical constant temperature chair pad is assembled with the chair seat. The physical constant temperature chair pad includes a mask bag 21 and a cushion layer, wherein: the pad Layer is made of constant temperature body 22, thermal insulation layer 24 and protective layer 25, and thermal insulation layer 24 is set below constant temperature body 22, and the material of thermal insulation layer 24 can be selected palm silk class materials such as coconut palm, mountain palm for use, also can select for use Sponge-like foam materials, utilizing their certain elasticity and thermal insulation performance, the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com