How to make lighting panels

A production method and technology for lighting panels, which are applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of reducing the light transmittance of products, obvious reflected light spots, poor working environment, etc., and achieve unique raw material formula, High light transmittance and scientific production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

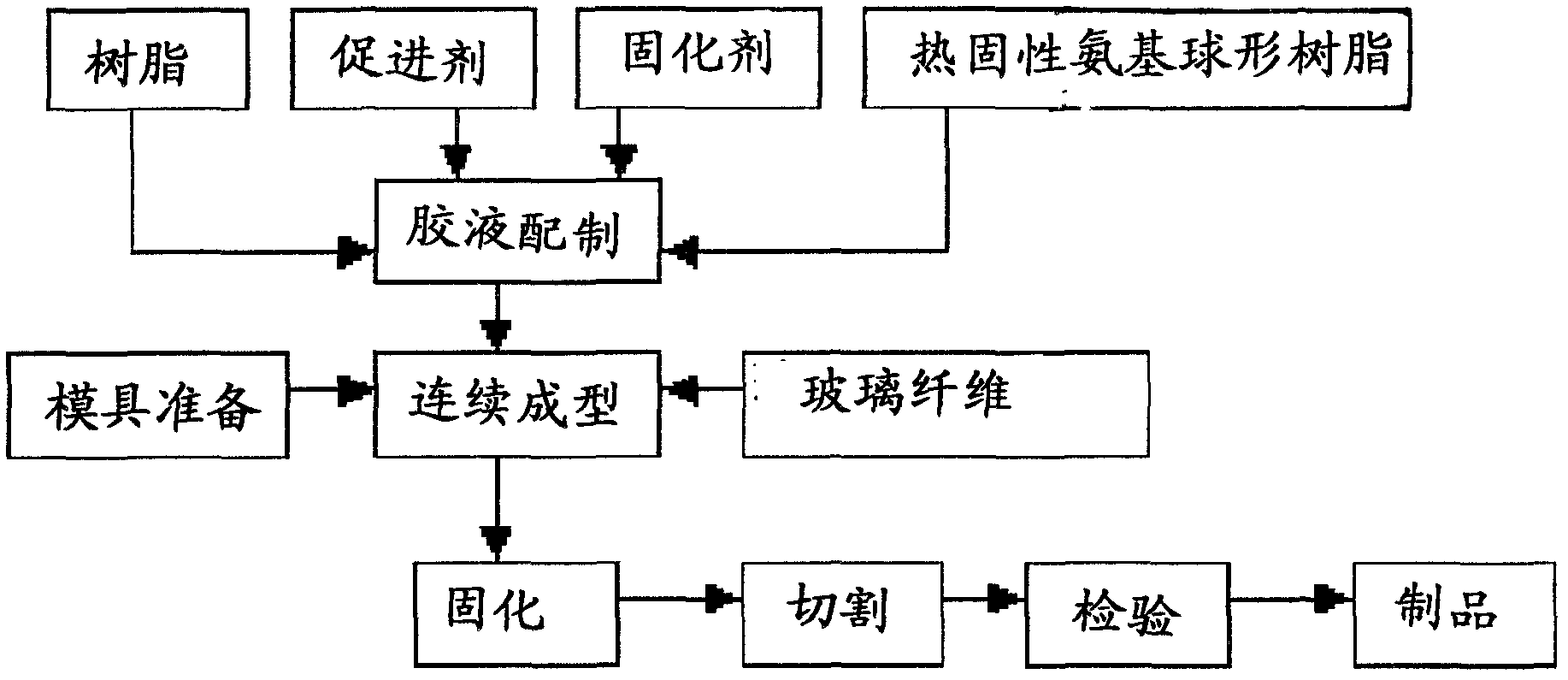

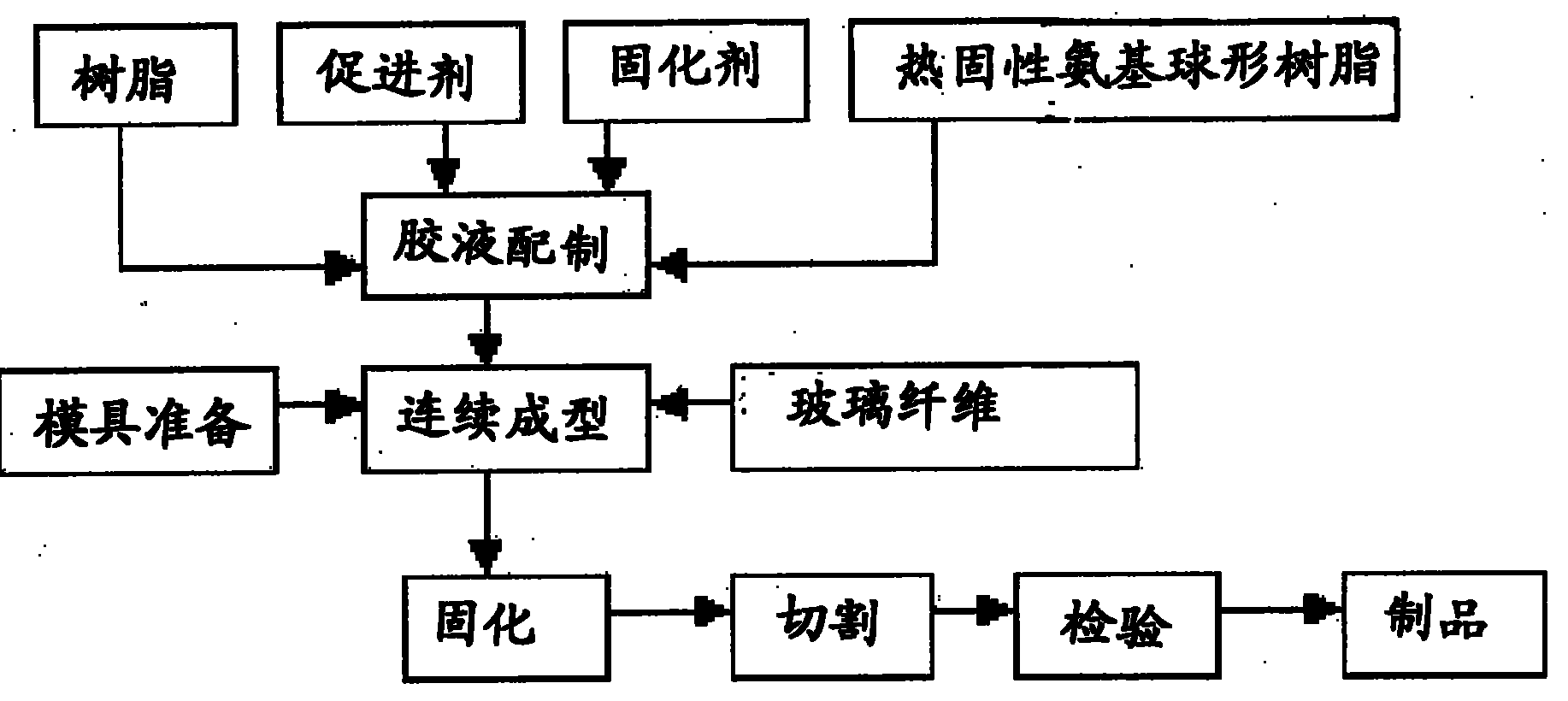

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] This embodiment is a manufacturing method of a daylighting board, which can also be called a manufacturing method of a SKET board. The resin is used as the base material, and the raw materials for forming the sky lighting board are 100 parts of resin, 1.5-2.5 parts of curing agent, 0.5-1.5 parts of accelerator and 0.3 parts of thermosetting amino spherical resin powder according to parts by weight.

[0018] Its preferred scheme is: 100 parts of resin, 2.0 parts of curing agent, 0.5 parts of accelerator, and 0.3 parts of thermosetting amino spherical resin powder.

[0019] The resin that the present invention adopts is the phthalic polyester resin produced by Tianjin Giant Star Co., Ltd. and Qinhuangdao Keruier Co., Ltd., the curing agent is methyl ethyl ketone peroxide (MEKP) produced by Qinhuangdao Chilu Chemical Environmental Protection Co., Ltd. The product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com