Edible fungus growing process and equipment for agilawood oolong tea

A technology of oolong tea and agarwood, which is applied in tea processing before extraction, food shaping, food science, etc., can solve the problems of long production cycle and long cycle, and achieve the effects of increasing efficiency, mellow taste, and shortening flowering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

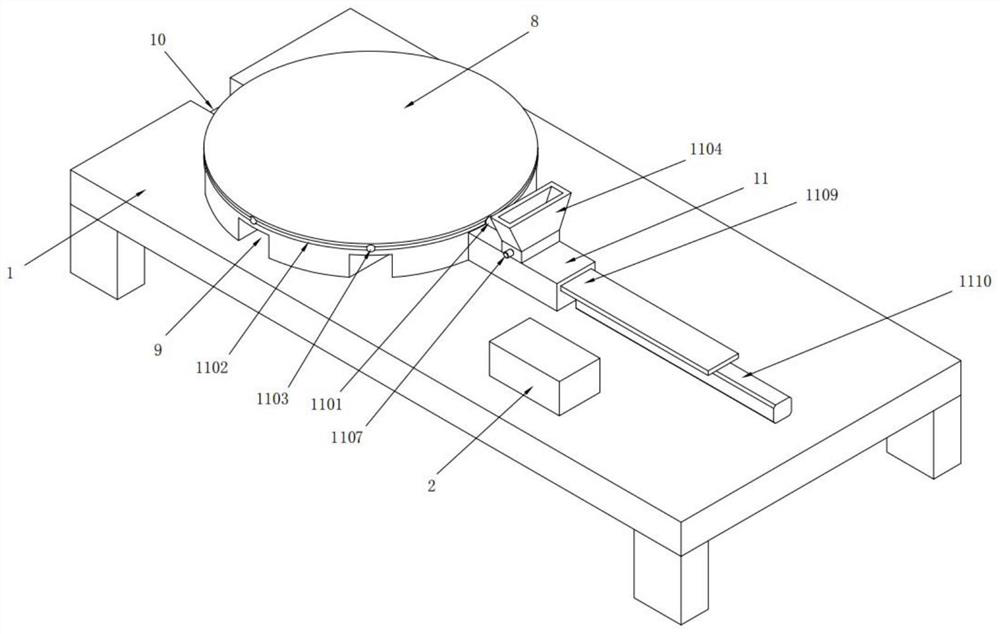

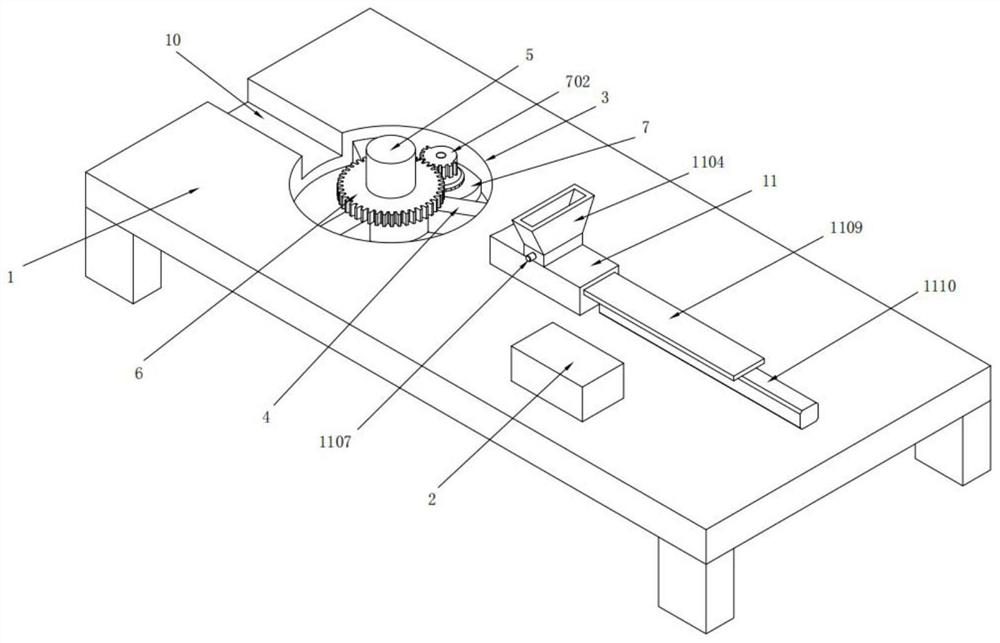

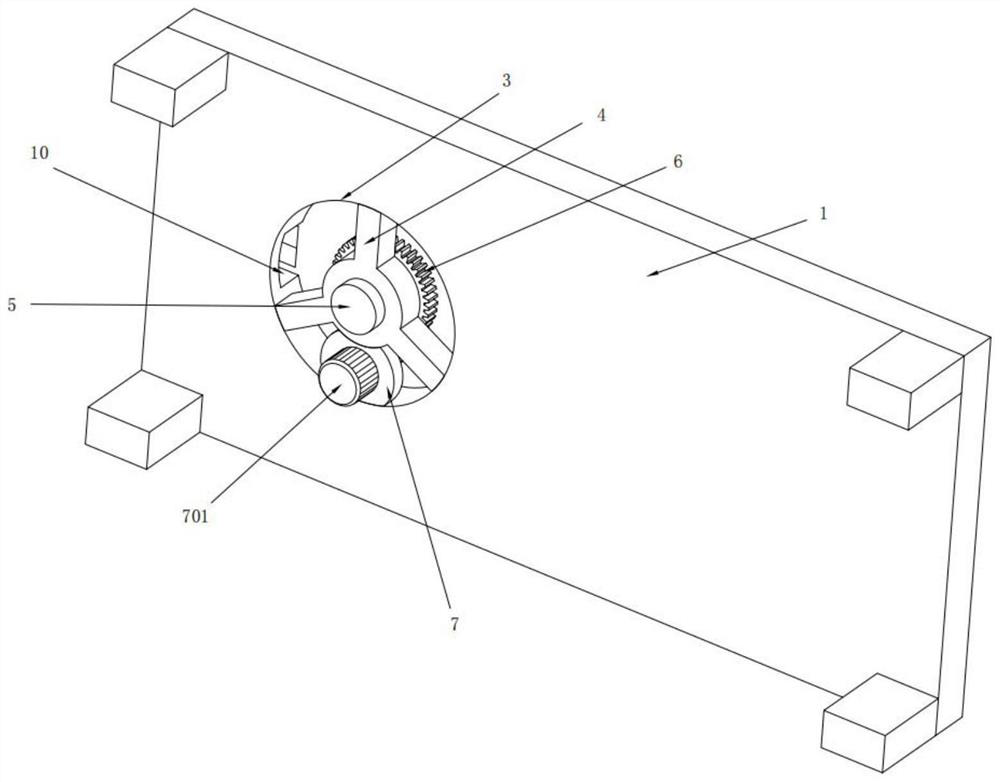

Method used

Image

Examples

Embodiment 1

[0067] An agarwood oolong tea blooming process, the production method comprising the following steps:

[0068] S1. Tea Blending

[0069] The raw materials are 40 parts by weight of Meizhan, 20 parts of Tieguanyin, 10 parts of Laotie, 12 parts of chopped tea stalks, and 1 part of agarwood leaves, and mix evenly;

[0070] S2. Steamed tea

[0071] The tea is steamed with steaming tea fermentation equipment, and the leaves are soft and non-thorny, and the water content is controlled to 18% to make tea base;

[0072] S3. Wodui

[0073] Stack the steamed tea dhool, control the pile temperature at 65°C to 70°C, and pile it up for 36 hours. The tea dhool has a mellow or jujube fragrance, and the leaves are soft and sticky to the touch.

[0074] S4. Mixed tea

[0075] Stir evenly according to the ratio of tea leaves: tea soup weight ratio = 10:1; tea soup is the liquid made from boiled tea leaves; The weight ratio of water is 1:10, just boil until the water boils;

[0076] S5. We...

Embodiment 2

[0087] An agarwood oolong tea blooming process, the production method comprising the following steps:

[0088] S1. Tea Blending

[0089] The raw materials are 50 parts by weight of Meizhan, 30 parts of Tieguanyin, 20 parts of Laotie, 15 parts of chopped tea stalks, and 5 parts of agarwood leaves, which are mixed evenly;

[0090] S2. Steamed tea

[0091] The tea is steamed by steaming tea fermentation equipment, and the leaves are soft and non-thorny, and the water content is controlled to 20% to make tea base;

[0092] S3. Wodui

[0093] Put the steamed tea dregs into piles, the pile temperature is controlled at 65°C to 70°C, and the pile time is 30 hours. The tea dregs have a mellow or jujube aroma, and the leaves are soft and sticky to the touch.

[0094] S4. Mixed tea

[0095]Stir evenly according to the ratio of tea leaves: tea soup = 10:1; the method of making tea soup is: take the in-process tea and add water to boil, the weight ratio of in-process tea to water is 1:...

Embodiment 3

[0107] An agarwood oolong tea blooming process, the production method comprising the following steps:

[0108] S1. Tea Blending

[0109] The raw materials are 60 parts by weight of Meizhan, 40 parts of Tieguanyin, 30 parts of Laotie, 18 parts of chopped tea stalks, and 10 parts of agarwood leaves, which are mixed evenly;

[0110] S2. Steamed tea

[0111] Use steaming tea fermentation equipment to steam the tea, the leaves should be soft and thorn-free, and the water content should be controlled to 24% to make tea base;

[0112] S3. Wodui

[0113] Put the steamed tea dregs into piles, the pile temperature should be controlled at 75°C to 75°C as much as possible, and the stacking time should be 24 hours. The tea dregs should have a mellow aroma or jujube fragrance, and the leaves should be soft and sticky to the touch.

[0114] S4. Mixed tea

[0115] Stir evenly according to the ratio of tea leaves: tea soup = 10:1; the method of making tea soup is: take the in-process tea a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com