Electric bus battery quick change system

A technology for quick battery replacement and electric bus, applied in electric power units, power units, vehicle components, etc., can solve the problems of shortening battery life, poor scalability of battery swapping equipment, and inability to close charging shelves, so as to reduce space occupation. efficiency, improve service life, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

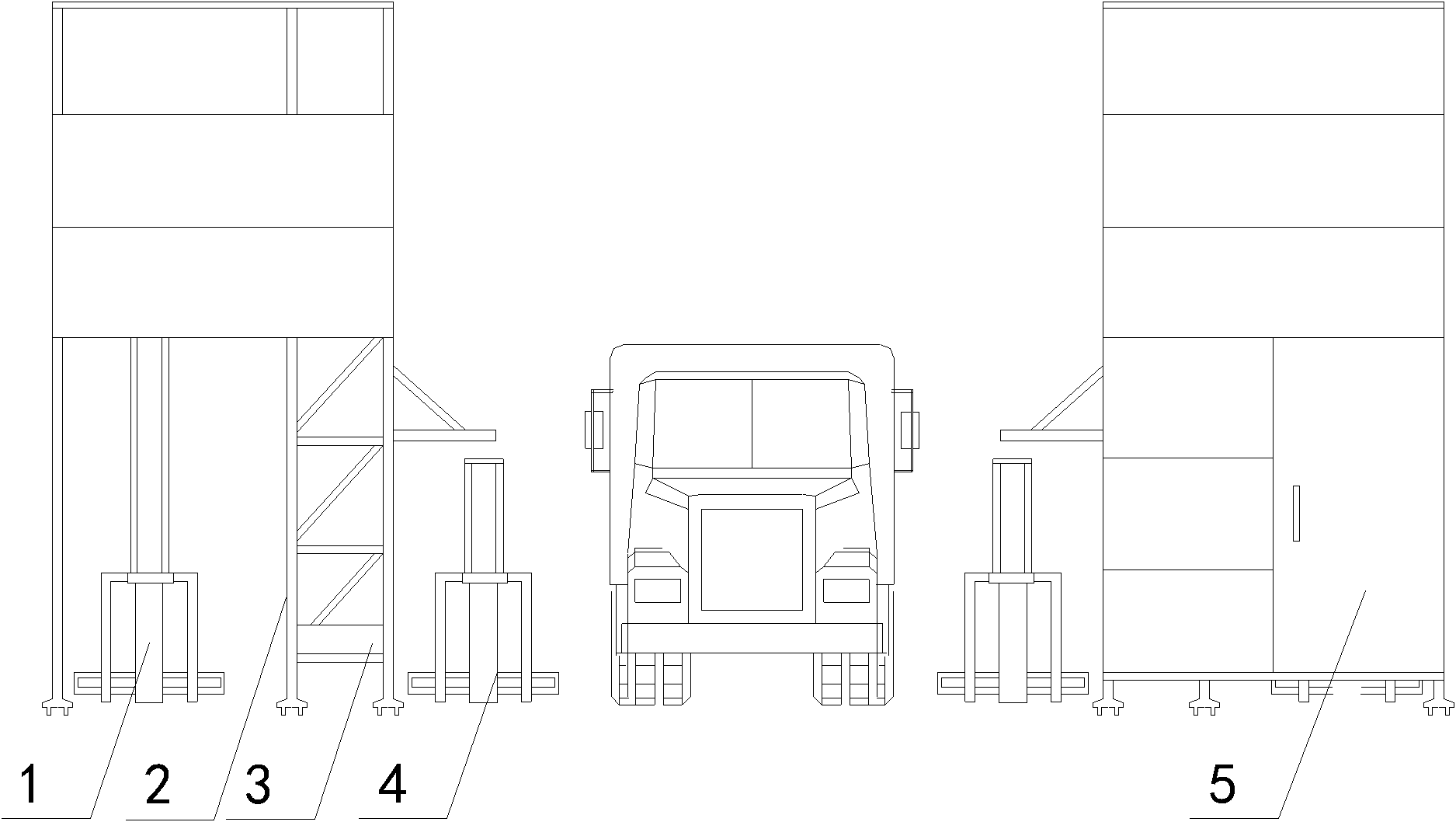

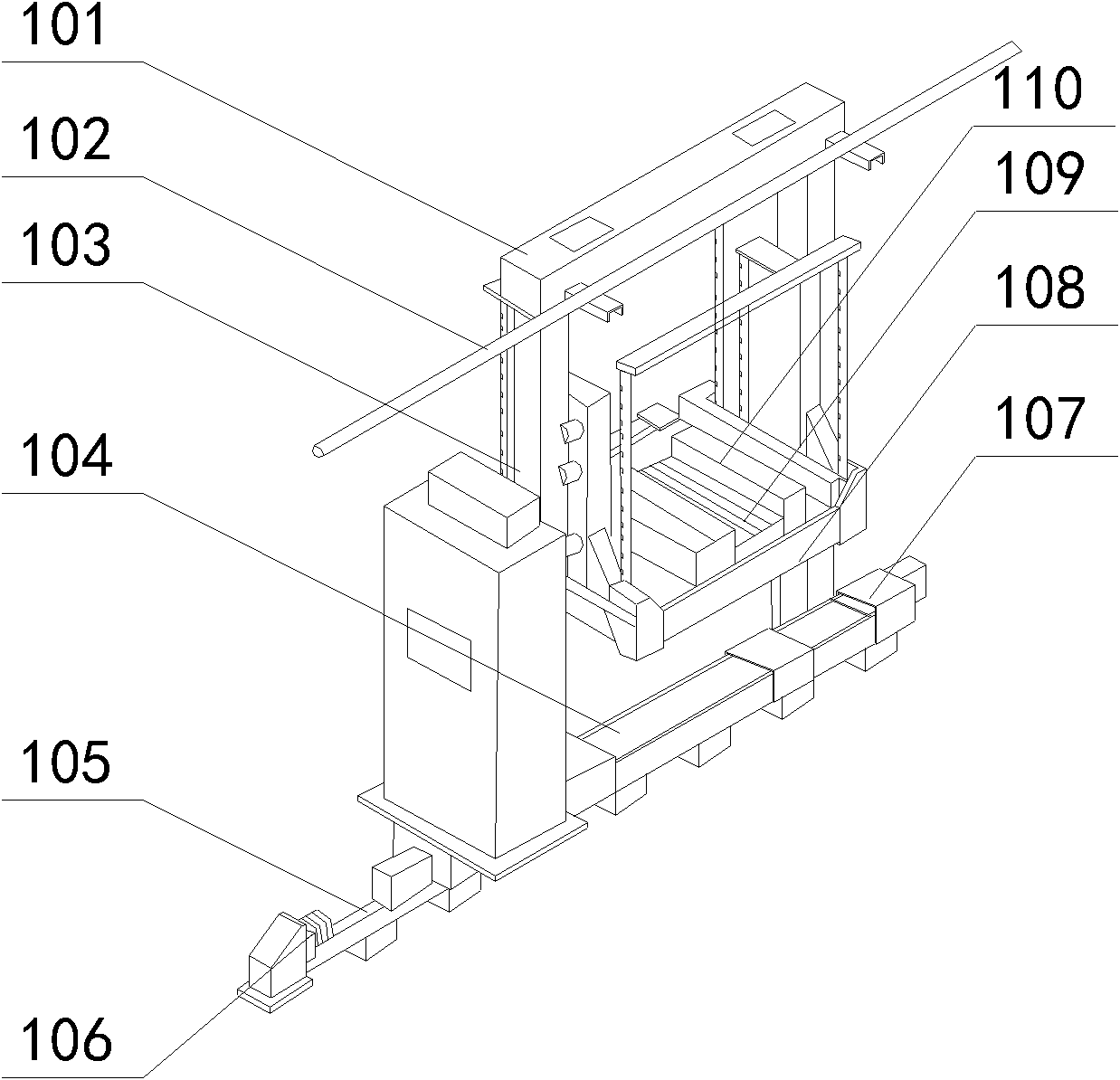

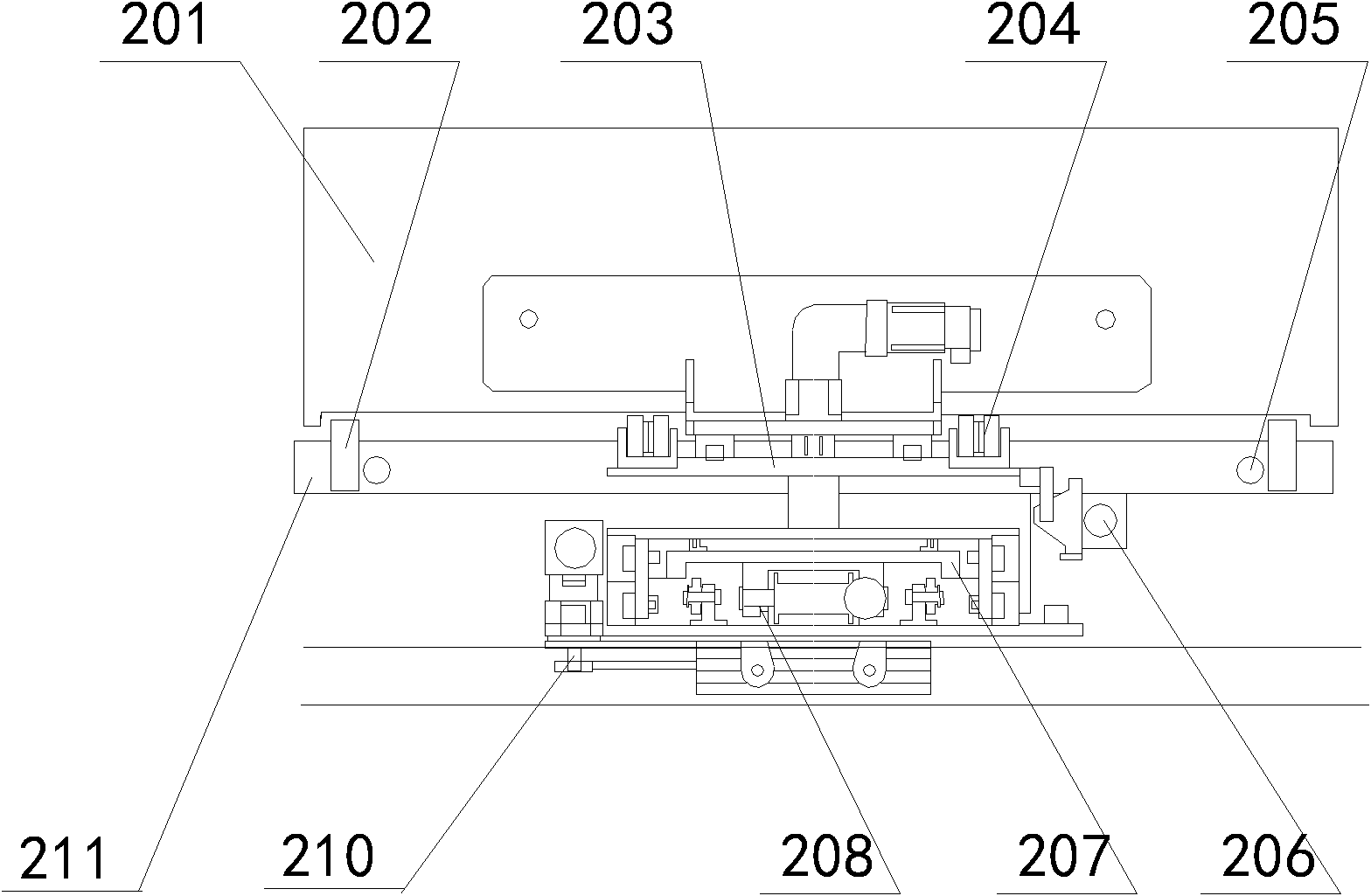

[0029] Such as Figure 1-5 As shown, a battery quick change system for an electric bus includes a charging shelf 2, a transfer platform 3 is provided in the middle of the bottom layer of the charging shelf 2, a stacker 1 connected to the charging shelf 2 is provided on the outside of the transfer station 3, and a stacker 1 connected to the charging shelf 2 is provided on the inner side. There is a quick-change robot 4 matched with the transfer platform 3, and the charging rack 2, the transfer platform 3, the stacker 1 and the quick-change robot 4 are all connected to the console 5 through lines.

[0030] The charging rack 2 includes a frame that is evenly arranged in a matrix and divided into several charging positions 404. Each charging position 404 is provided with a guide rail I 403 and a charging device. The charging position 404 can be used for eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com