A special reaction kettle for the preparation of hydrofluoric acid

A reaction kettle and hydrofluoric acid technology, applied in the direction of fluorine/hydrogen fluoride, etc., can solve the problems of high metal ion content, inability to remove, affect the quality of hydrofluoric acid, etc., to achieve the effect of ensuring quality and reducing metal ions

Inactive Publication Date: 2011-12-14

无锡东风新能源科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The reaction kettle for the preparation of existing hydrofluoric acid directly uses steel cylinder or full-carbon steel, and the reactor is produced under the direct heating of water or steam, and the metal ions of steel cylinder or full-carbon steel will enter in the hydrofluoric acid, As a result, the content of metal ions in hydrofluoric acid is high, reaching 1ppm, which is only suitable for corrosion in diodes. The products are AR grade, GR grade, and EL grade

The industry adopts stainless steel kettle body or graphite kettle body, and sets the additive inlet on the kettle body, and realizes the control of metal ions in hydrofluoric acid in the kettle by adding additives. This method will not lead to metal ions in hydrofluoric acid Increase, to a certain extent improve the quality of hydrofluoric acid, but the metal ions doped in the raw material of anhydrous hydrogen fluoride cannot be completely removed by additives, thus affecting the quality of hydrofluoric acid

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

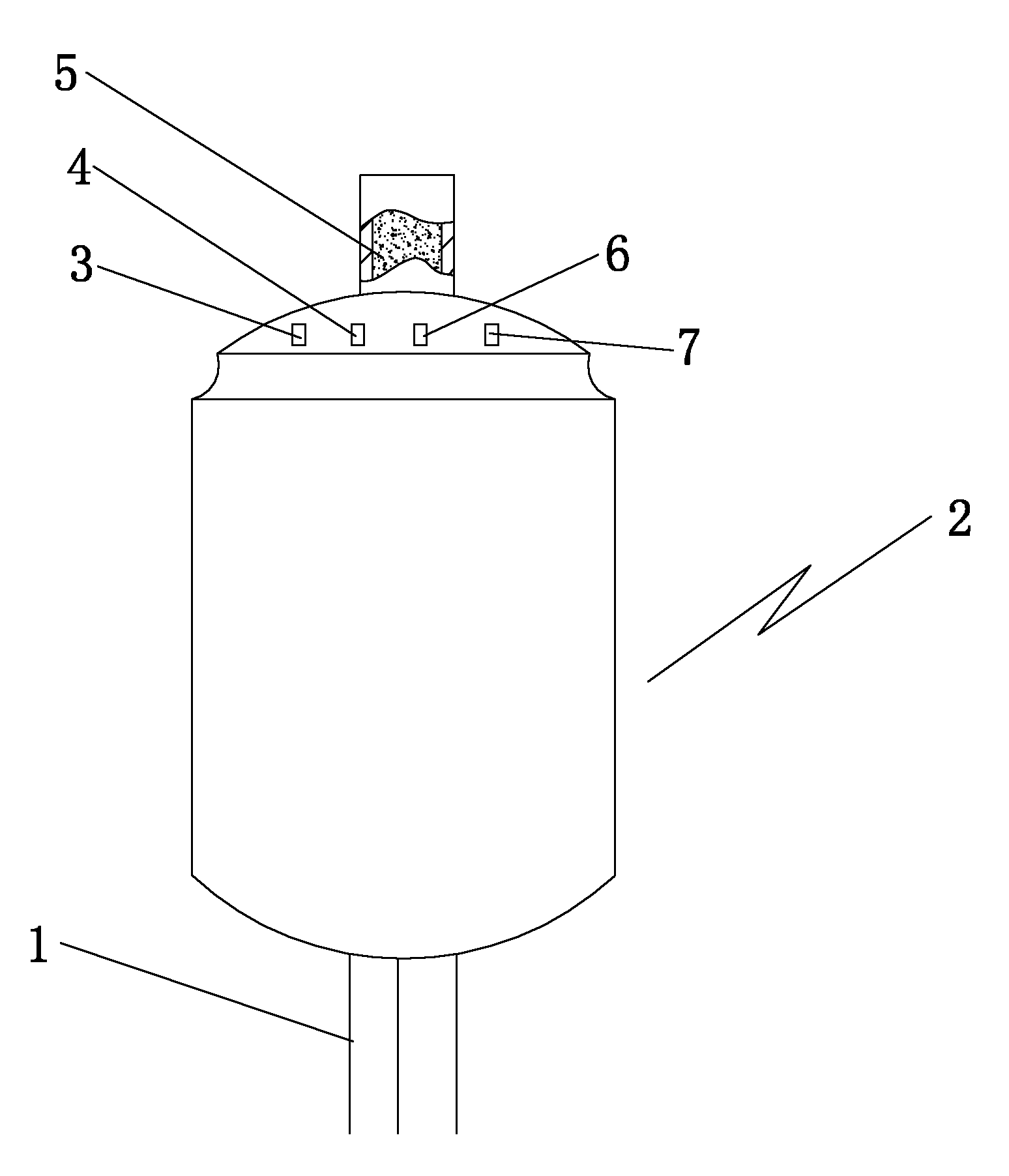

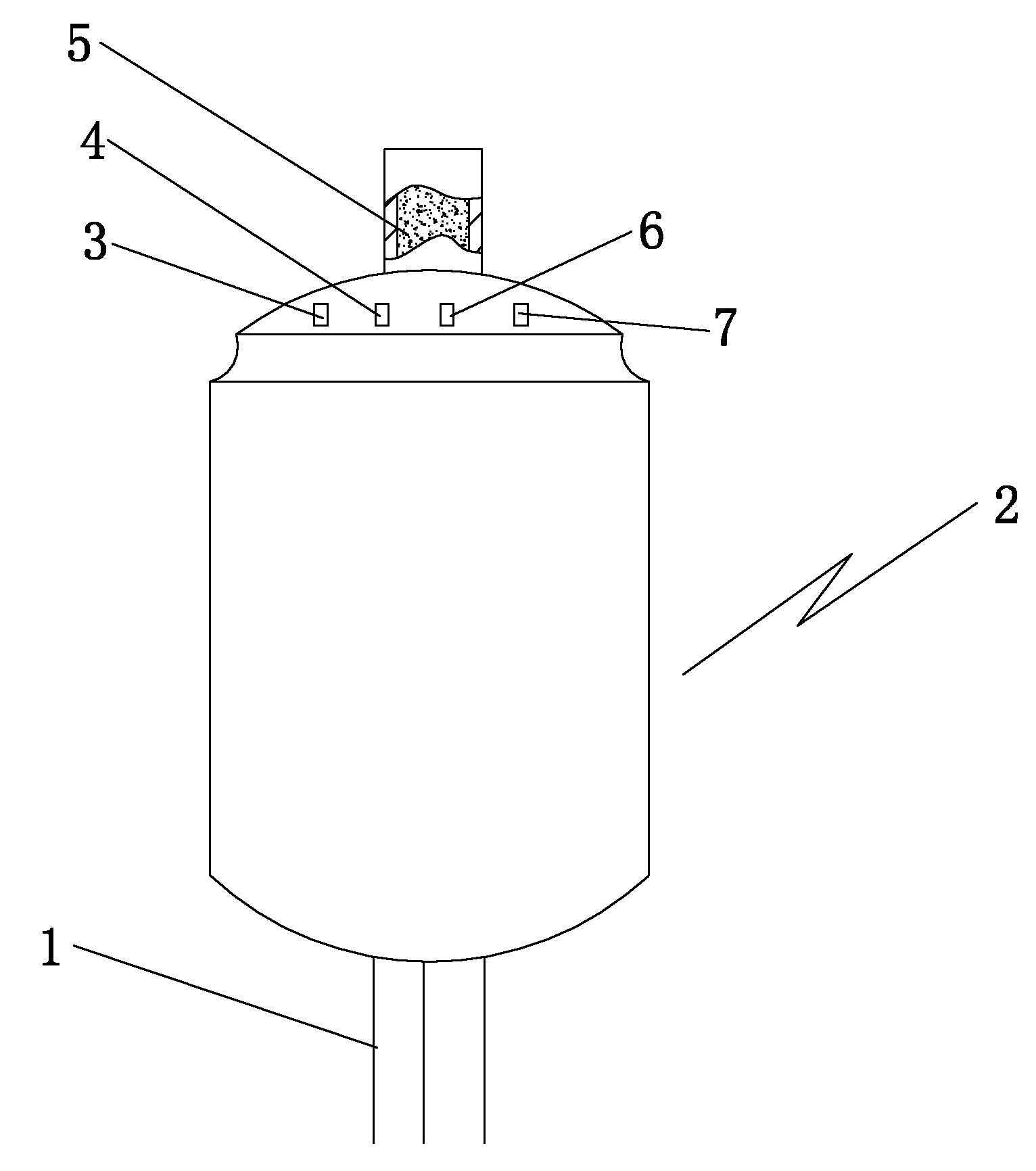

[0007] See figure 1 , the present invention includes a reactor body 2, the reactor body 2 is provided with a feed inlet 3, a discharge port, and an additive inlet 4, and the kettle body 2 of the reactor is a stainless steel kettle body or a graphite kettle body, and the reactor body 2 is provided with a There is a packing layer 5 of PTFE material. 6 is a thermometer hole, 7 is a pressure gauge hole, and 1 is a support.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of chemical reaction kettles, in particular to a special reaction kettle for the preparation of hydrofluoric acid. It can realize the treatment of the hydrofluoric acid coming out of the reaction kettle, reduce the content of metal ions in the hydrofluoric acid, and ensure the quality of the hydrofluoric acid. It includes a reactor body, the reactor body is provided with a feed inlet, a discharge outlet, and an additive inlet, and the reactor body of the reactor is a stainless steel kettle body or a graphite kettle body, and is characterized in that: The mouth part is provided with a packing layer of tetrafluoro material.

Description

technical field [0001] The invention relates to the technical field of chemical reaction kettles, in particular to a special reaction kettle for the preparation of hydrofluoric acid. Background technique [0002] The reaction kettle for the preparation of existing hydrofluoric acid directly uses steel cylinder or full-carbon steel, and the reactor is produced under the direct heating of water or steam, and the metal ions of steel cylinder or full-carbon steel will enter in the hydrofluoric acid, As a result, the content of metal ions in hydrofluoric acid is relatively high, reaching 1ppm, which is only suitable for corrosion in diodes. The products are AR grade, GR grade, and EL grade. The industry adopts stainless steel kettle body or graphite kettle body, and sets the additive inlet on the kettle body, and realizes the control of metal ions in hydrofluoric acid in the kettle by adding additives. This method will not lead to metal ions in hydrofluoric acid The increase imp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B7/19

Inventor 王明

Owner 无锡东风新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com