Three-component thermal insulation, fireproof and sound insulation material and preparation method thereof

A fire-proof and sound-proof, three-component technology, applied in the field of heat-insulation and sound-insulation materials, can solve the problems of poor applicability, poor fire-proof performance, poor heat-insulation and sound-proof effect, etc. The effect of applying the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

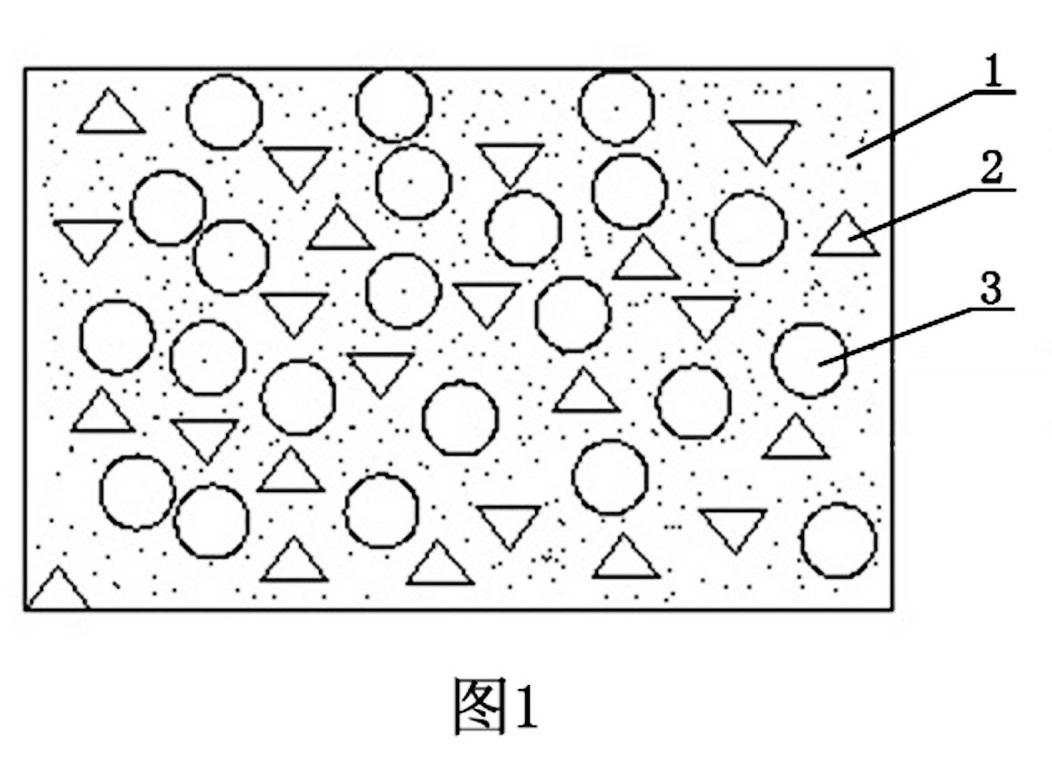

[0031] Embodiment 1, inorganic gelling material, graphite polystyrene particle and vitrified microbead particle ratio by volume percentage are as follows:

[0032] Inorganic gelling material 30%;

[0033] Polystyrene foam particles 30%;

[0034] Vitrified microbead particles 40%.

Embodiment 2

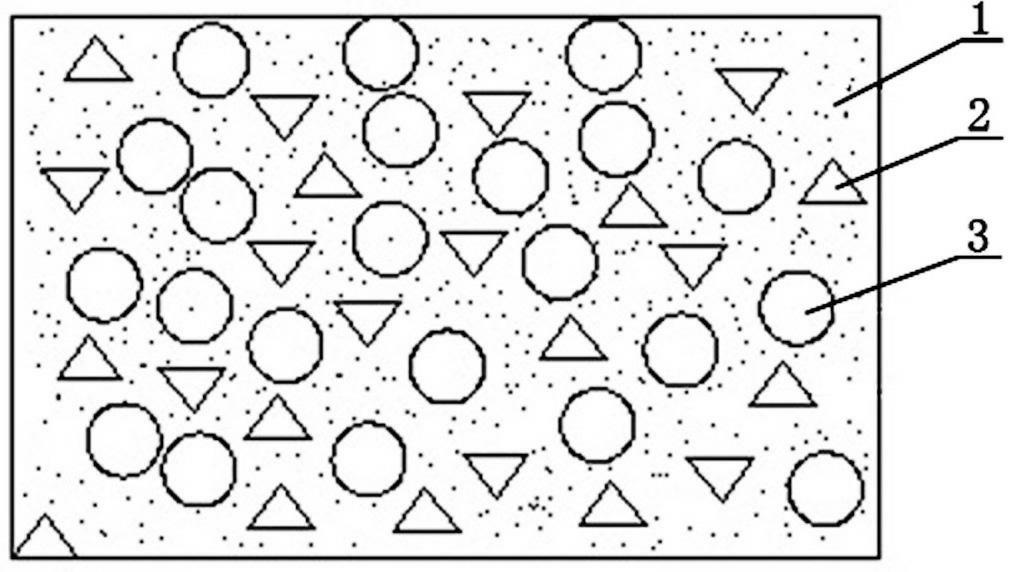

[0035] Embodiment 2, the ratio of inorganic gelling material, graphite polystyrene particles and vitrified microbead particles by volume percentage is as follows: inorganic gelling material 28%;

[0036] Polystyrene foam particles 40%;

[0037] Vitrified microbead particles 32%.

Embodiment 3

[0038] Embodiment three, inorganic gelling material, graphite polystyrene particle and vitrified microbead particle proportioning by volume percentage is as follows:

[0039] Inorganic gelling material 25%;

[0040] Polystyrene foam particles 35%;

[0041] Vitrified microbead particles 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com