multi-purpose scraper

A scraper, multi-functional technology, applied in the field of multi-functional scraper, can solve problems such as difficult maintenance and shortage of wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

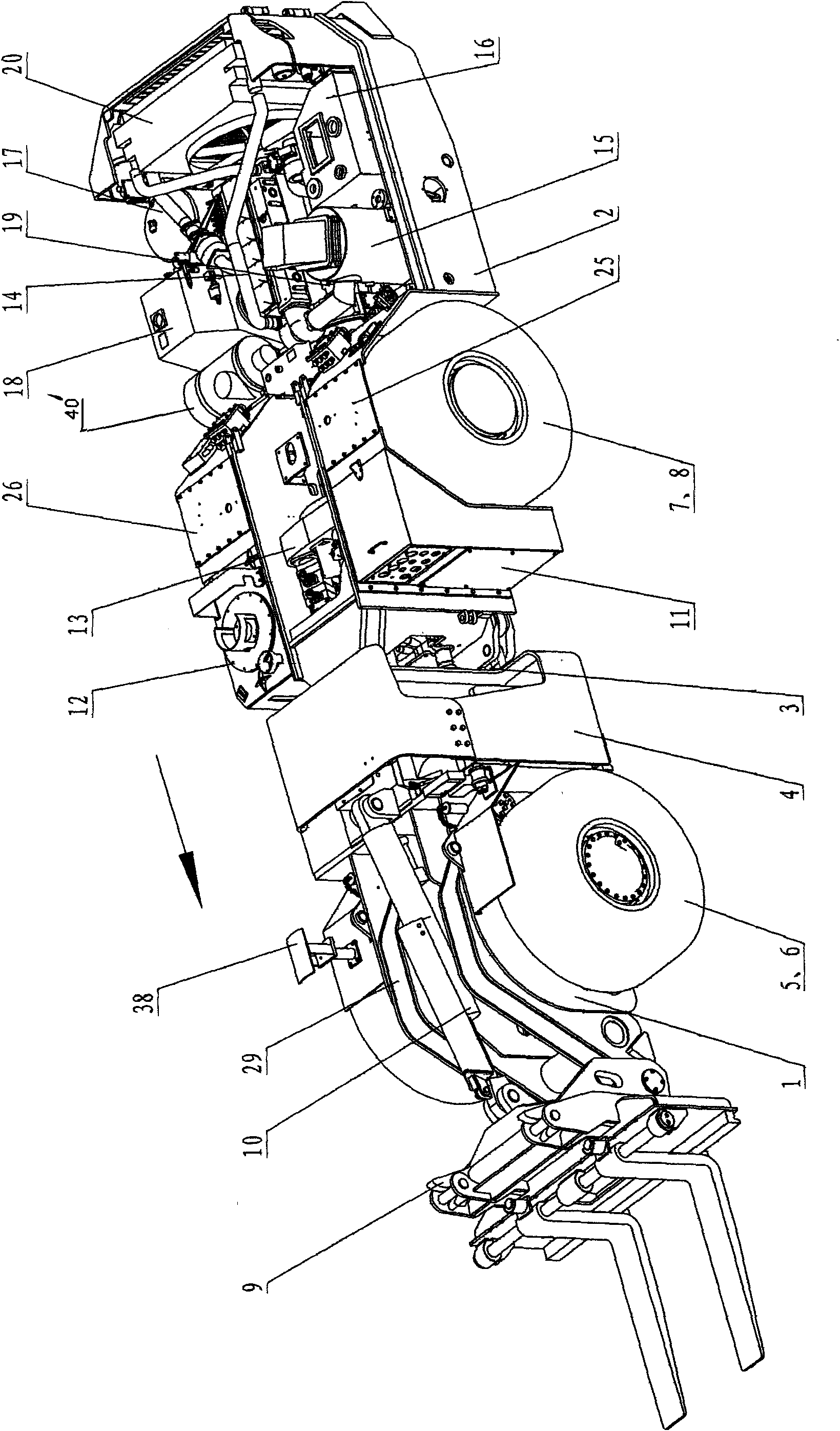

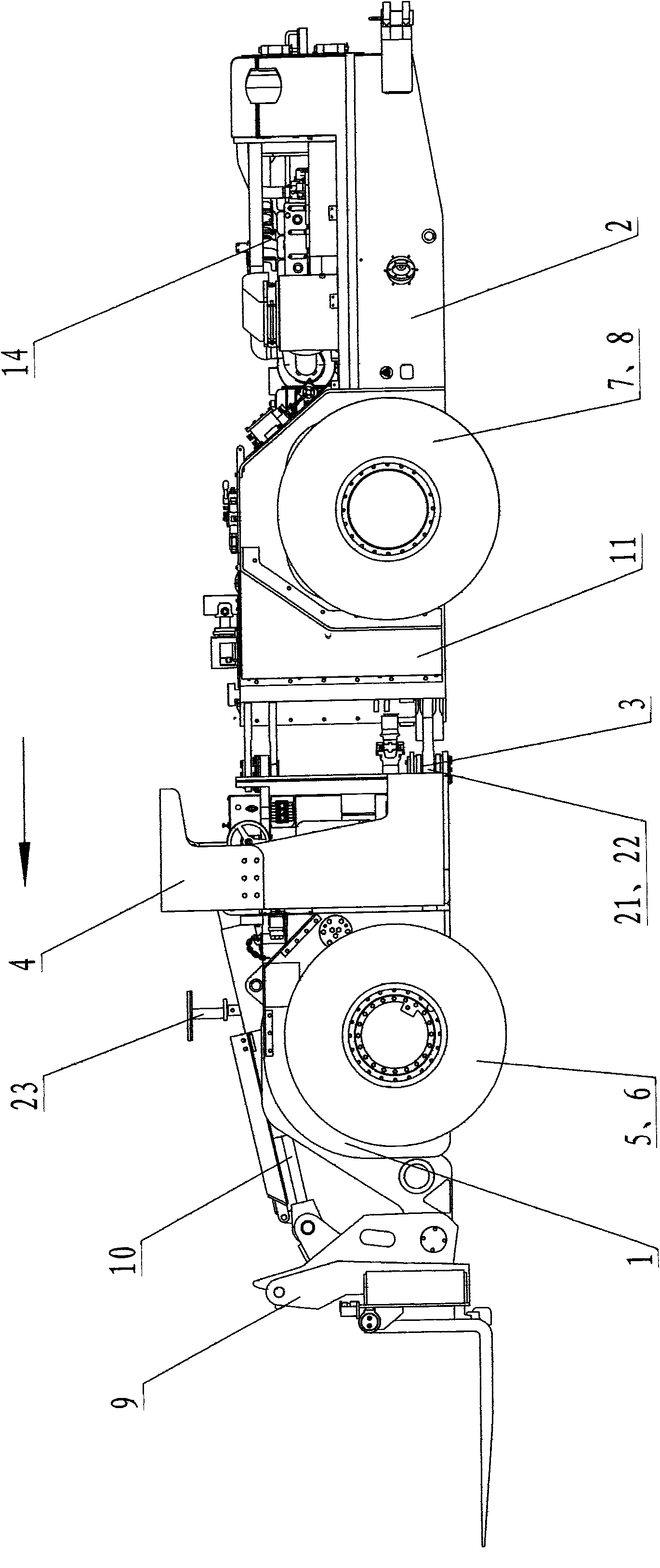

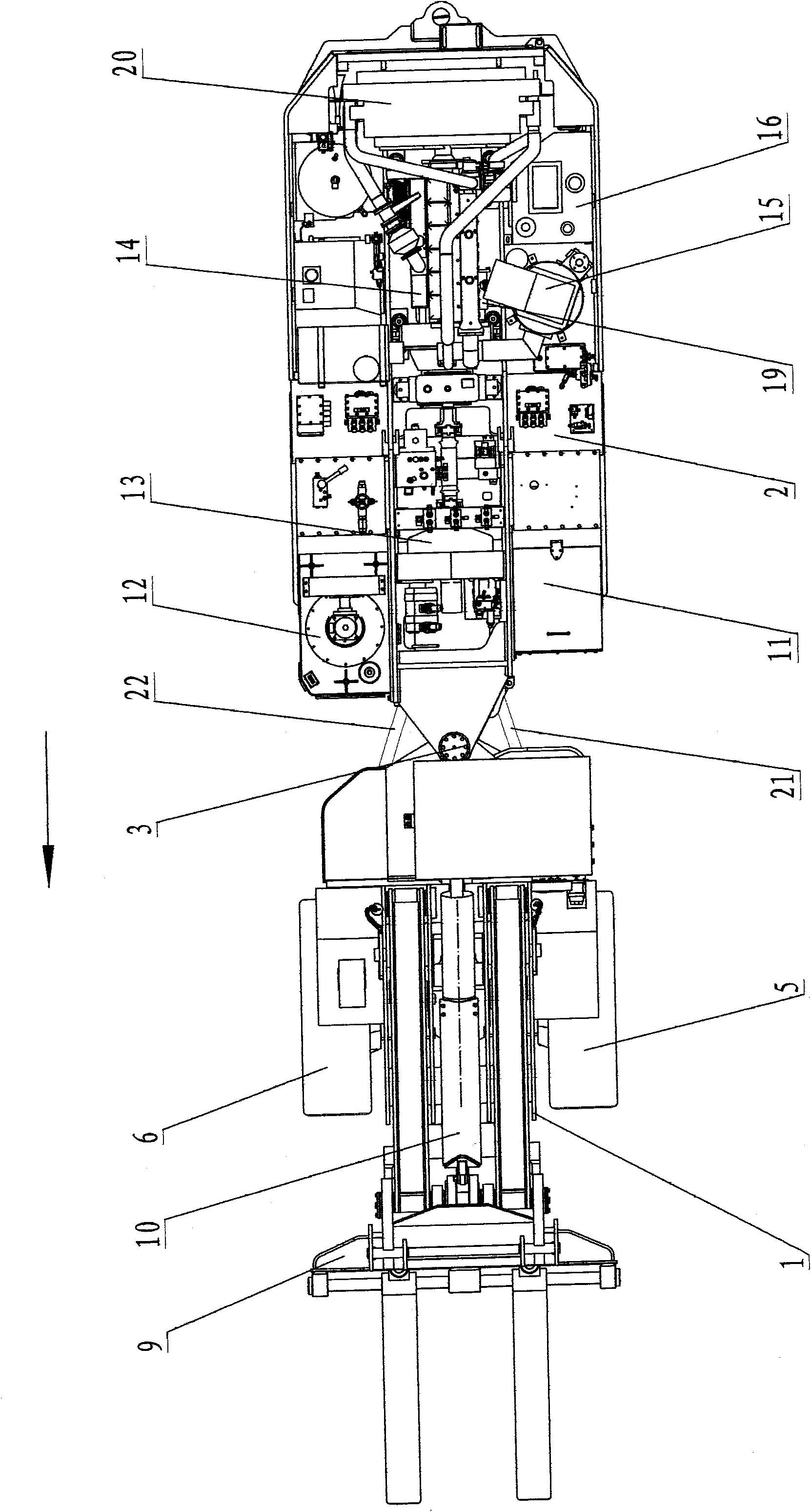

[0022] figure 1 , 2 . As shown in 3, it is the overall structure diagram of the scraper. The position and connection relationship of each part must be correct and the installation should be firm.

[0023] The front part of the scraper is the front frame 1, which is connected to the rear frame 2 through the hinged frame 3; The left rear wheel 7 and the right rear wheel 8 are arranged symmetrically; the cab 4 is arranged at the rear of the front frame 1, and the cab 4 is connected to the scraper quick-change mechanism 9 at the front through the tilting oil cylinder 10 and the left and right lever beams 29 and 30 The upper right part of the front frame 1 is provided with an illuminating lamp 38; the middle position of the rear upper part of the rear frame 2 is an explosion-proof diesel engine 14, and the left part of the explosion-proof diesel engine 14 is provided with a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com