A linear guide rail ultrasonic suspension extrusion film hydrostatic bearing

A linear guide rail and hydrostatic bearing technology, applied in the field of bearings, to achieve the effects of low wear, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

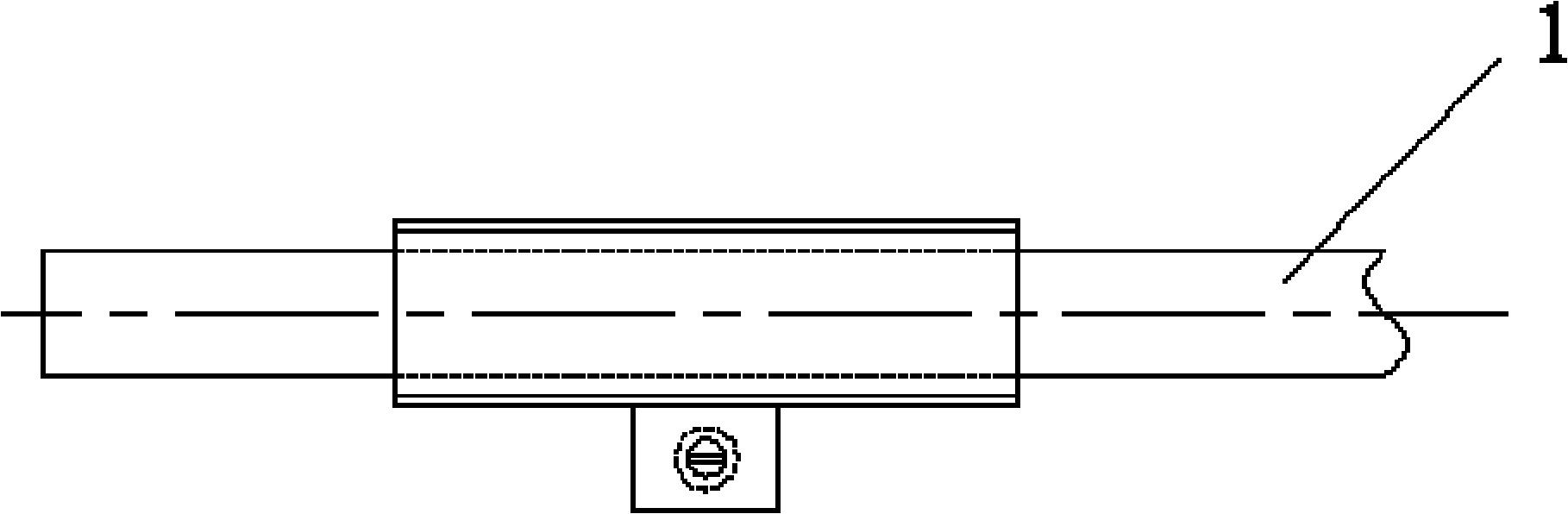

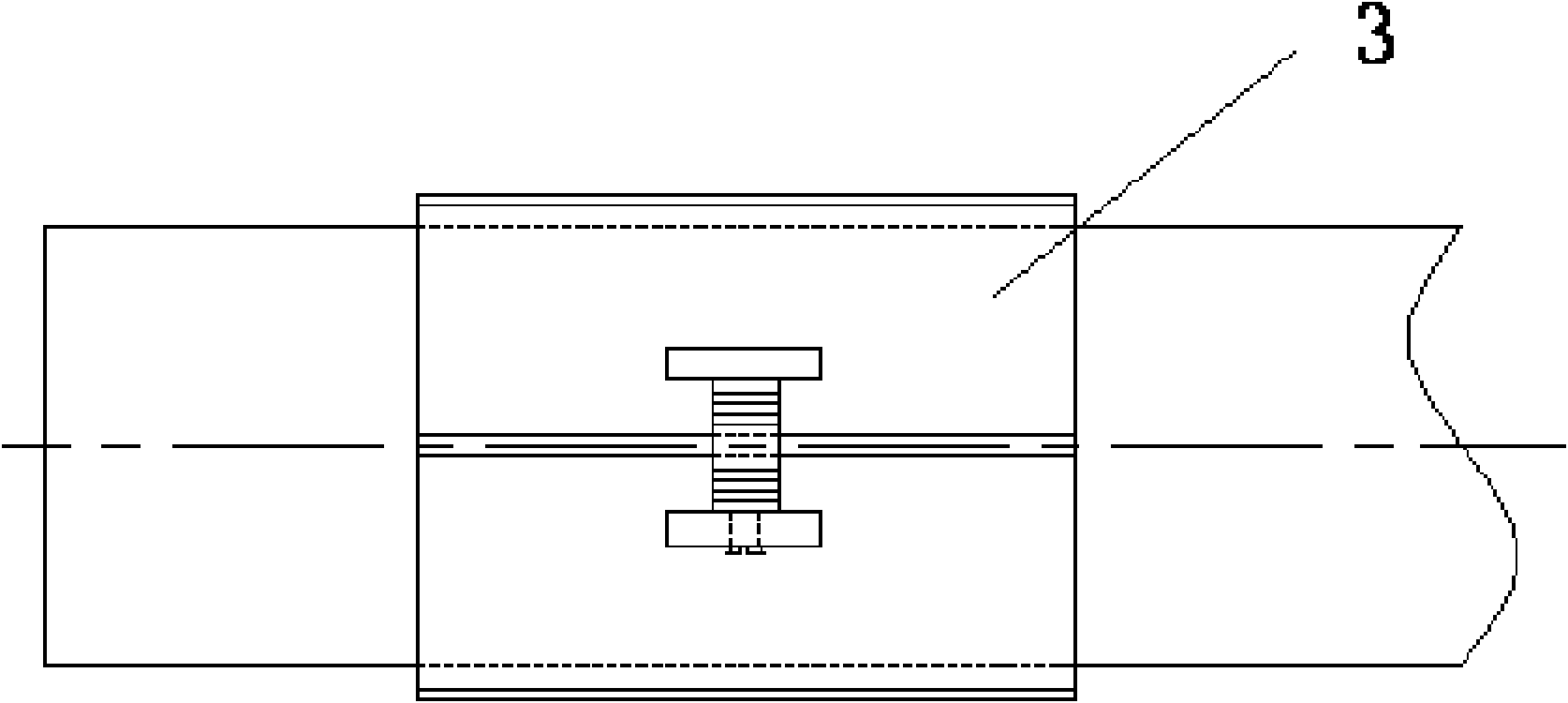

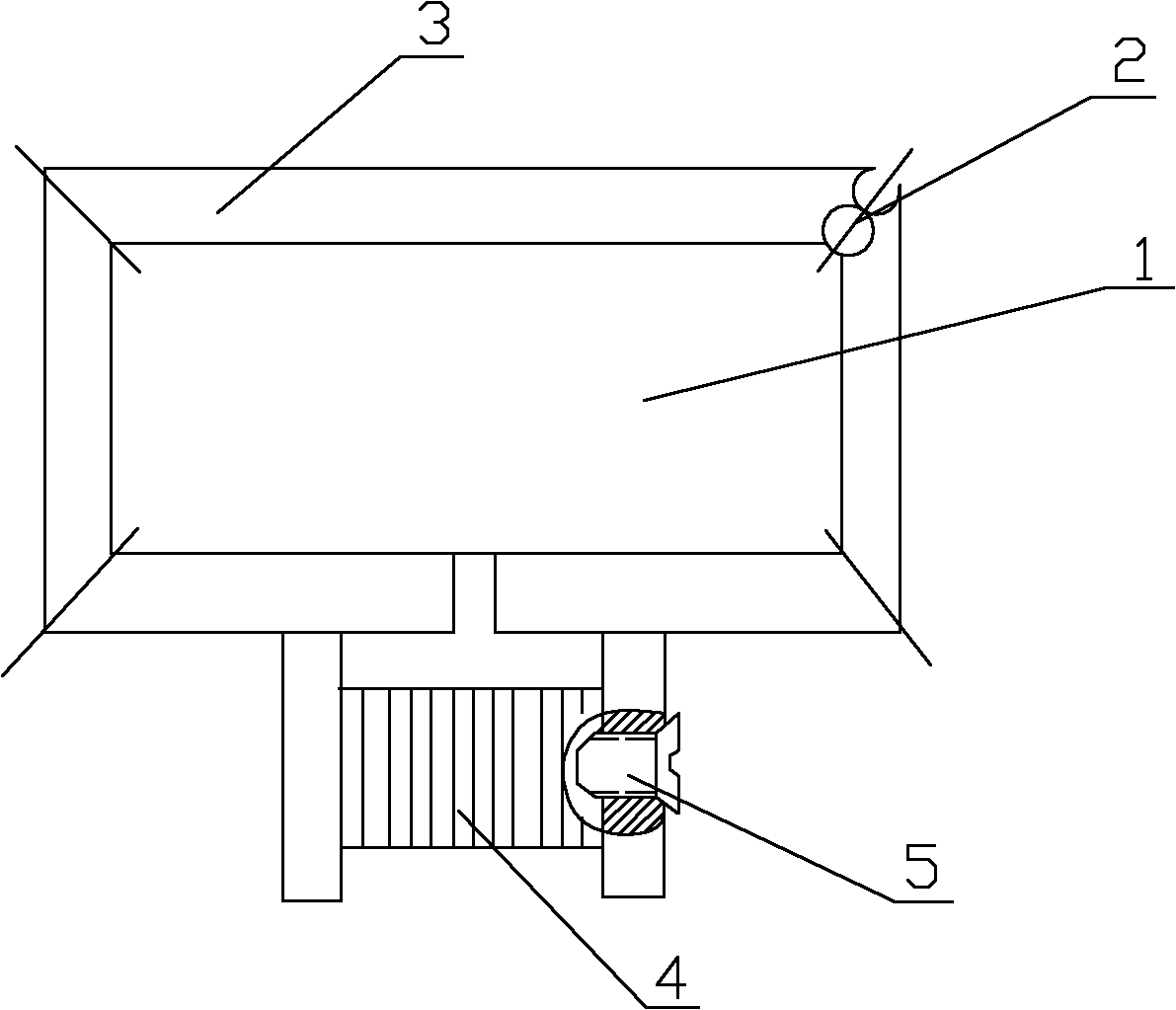

[0014] The present invention will be further described below in conjunction with drawings and embodiments. The linear guide rail ultrasonic suspension extruded film hydrostatic bearing includes a piezoelectric stack actuator 4, a fastening screw 5, a suspension bushing 3 and a flexible hinge 2, the suspension bushing 3 is installed on the linear guide rail 1, and the suspension bushing 3 is composed of four The two surfaces are connected by a flexible hinge 2 to form a rectangular bushing, and one of the four rectangular faces of the suspension bushing 3 has an air gap opening with a width of 2 mm. Fastening is provided on both sides of the air gap opening The vertical wall of the piezoelectric stack actuator 4 , a group of piezoelectric stack actuators 4 are fastened on the vertical wall by fastening screws 5 , and the initial preload is adjusted by adjusting the fastening screws 5 .

[0015] When the bearing system of this embodiment is working, the piezoelectric stack actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com