Coaxial integrated air spring shock absorber with controllable stiffness and damping linkage

An air spring, one-piece technology, applied in the direction of spring/shock absorber, shock absorber, spring, etc., can solve the problems of high efficiency, practicality, convenience, many parts of shock absorber control mechanism, poor stability, etc., to achieve Improve self-adaptive ability, simplify structure and improve processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

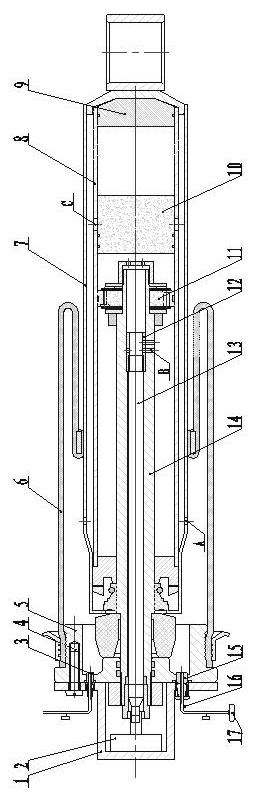

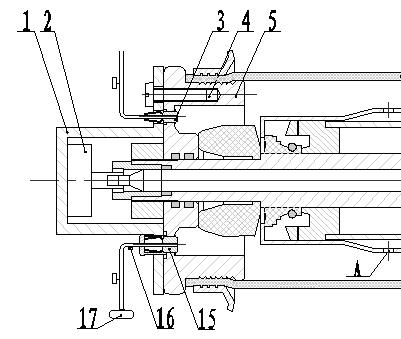

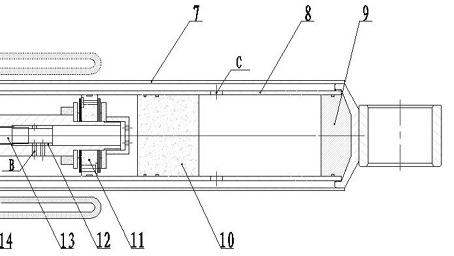

[0016] exist figure 1 Among them, the upper sealing plate 5 and the cage 1 securely connect the stepping motor 2 to the main body of the air spring shock absorber. The rotating shaft 13 is sleeved in the piston rod 14, and connects the spool 12 and the output shaft of the stepping motor 2. The stepper motor drives the rotating shaft 13 and the spool 12 to rotate under the control of the ECU, changing the number of small holes overlapping the spool and the piston rod, thereby changing the damping force of the shock absorber. The floating piston 10, the lower sealing cover 9, and the inner tube 8 constitute the main air chamber of the air spring, which is also the floating air chamber of the shock absorber. The inner tube 8 and the outer tube 7 form an annular air channel, and the outer tube 7 and the rubber air bag 6 form a secondary air chamber of the air spring. The piston assembly 11 divides the hydraulic chamber into a recovery chamber and a compression chamber. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com