Cutting reducer for roadheader

A technology of roadheader and reducer, which is applied in the direction of mechanical equipment, slitting machinery, driving device, etc., to achieve the effect of reducing production cost, improving operation accuracy and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

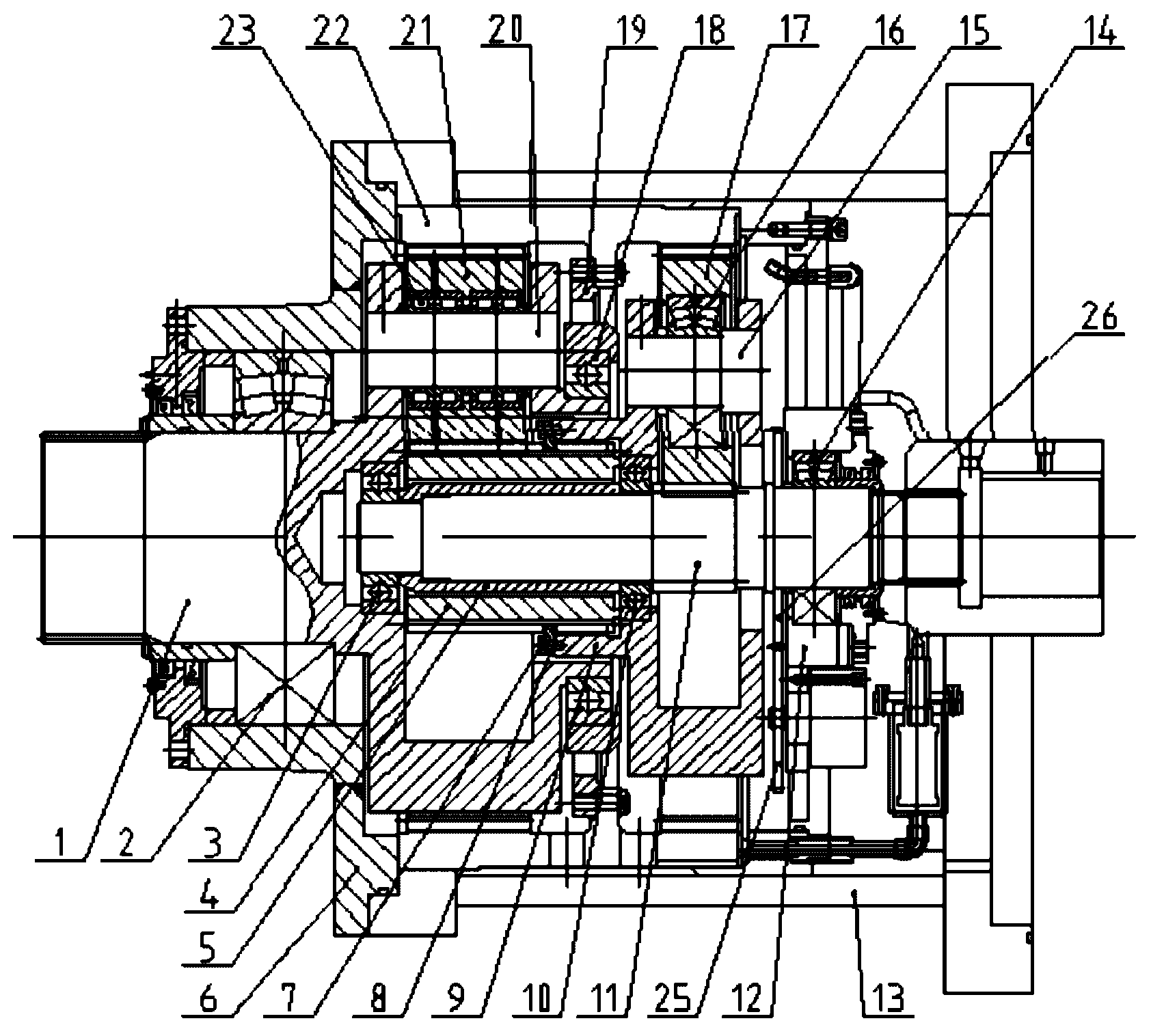

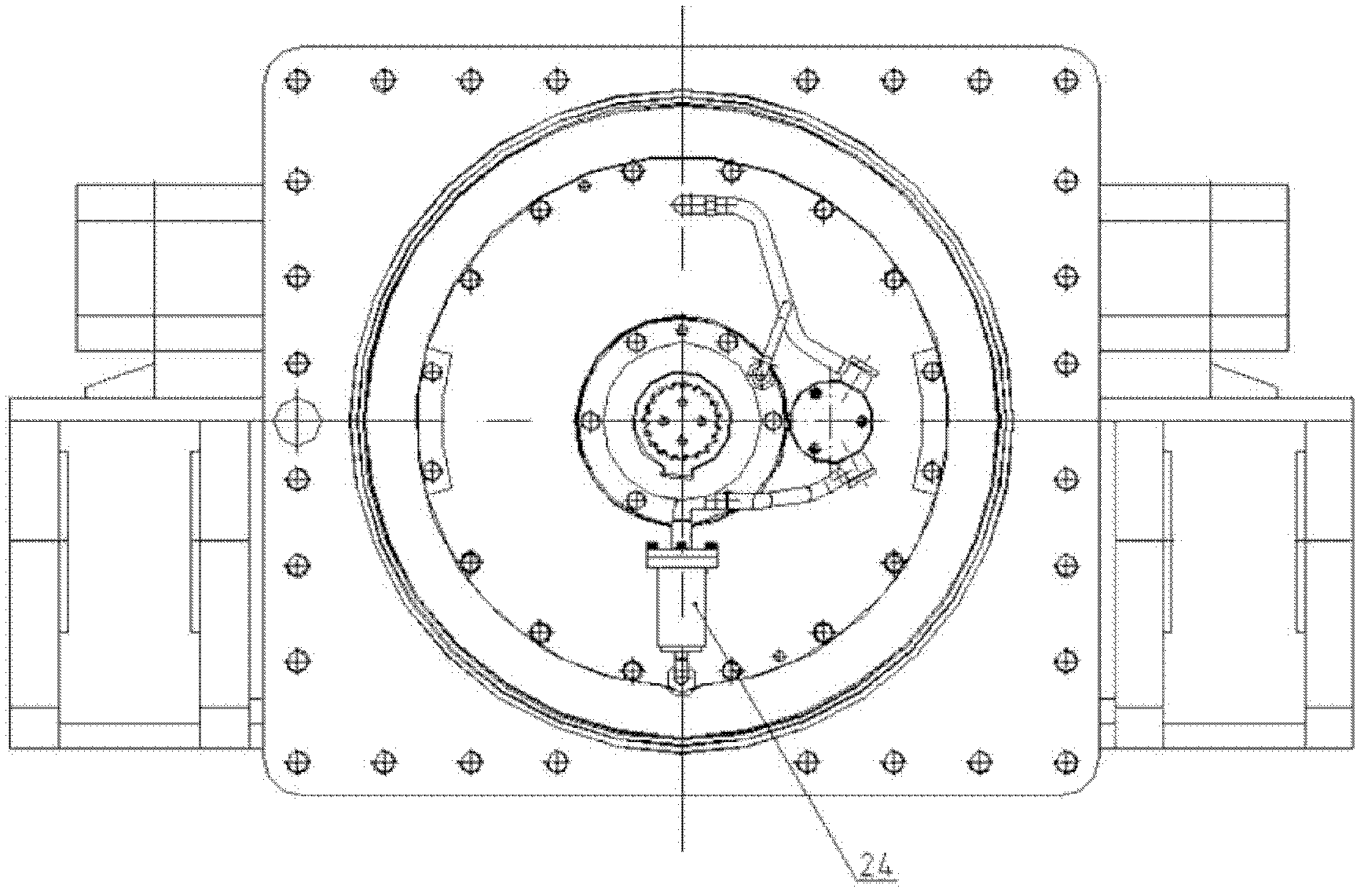

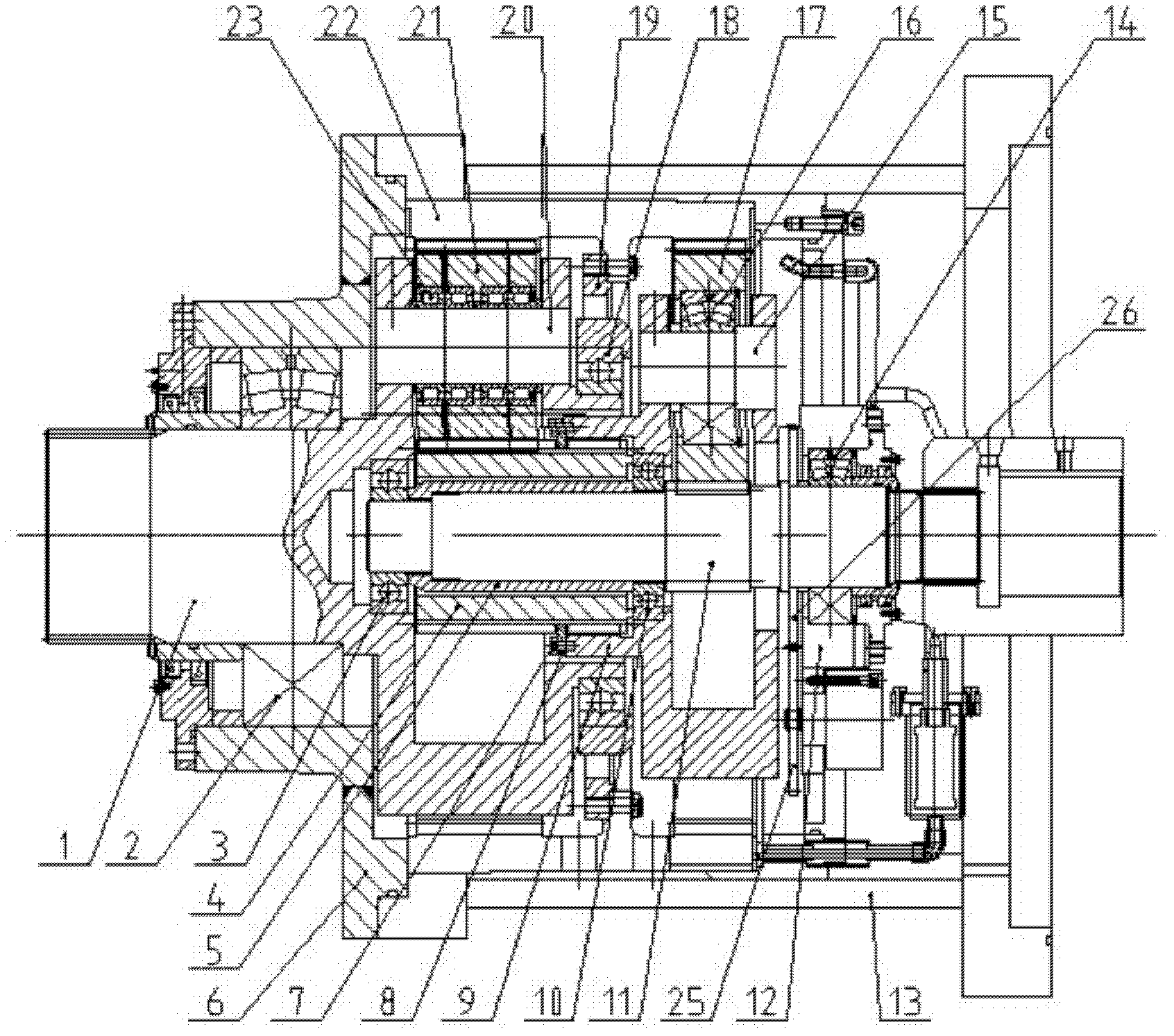

[0018] Such as figure 1 , 2 The cutting reducer of a roadheader shown includes a secondary planet carrier 1, a spherical roller bearing I 2, a deep groove ball bearing I 3, a secondary sun gear 4, a shaft sleeve 5, and an output bearing support 6. Bolt 7, baffle 8, primary planet carrier 9, deep groove ball bearing II 10, primary sun gear 11, input bearing support 12, box 13, spherical roller bearing II 14, primary planetary wheel shaft 15. Spherical roller bearing III 16, primary planetary gear (17), deep groove ball bearing III 18, support 19, secondary planetary shaft 20, secondary planetary gear 21, inner gear 22, cylindrical roller bearing 23. Lubrication system 24, driven gear 25, driving gear 26, characterized in that the first-stage sun gear 11 is installed on the input bearing support 12 and the second bearing through a spherical roller bearing II 14, a deep groove ball bearing I 3 The secondary planet carrier 1 is installed on the output bearing support 6 and the su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap