Bimetal composite pipe and preparation method thereof

A bi-metal composite pipe and outer pipe technology, applied in the field of composite pipes, can solve the problems of wear of the inner wall of the pipe, weak impact resistance, increased processing difficulty, etc., and achieve the effect of prolonging the service life, cost-effective, and avoiding being pulled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

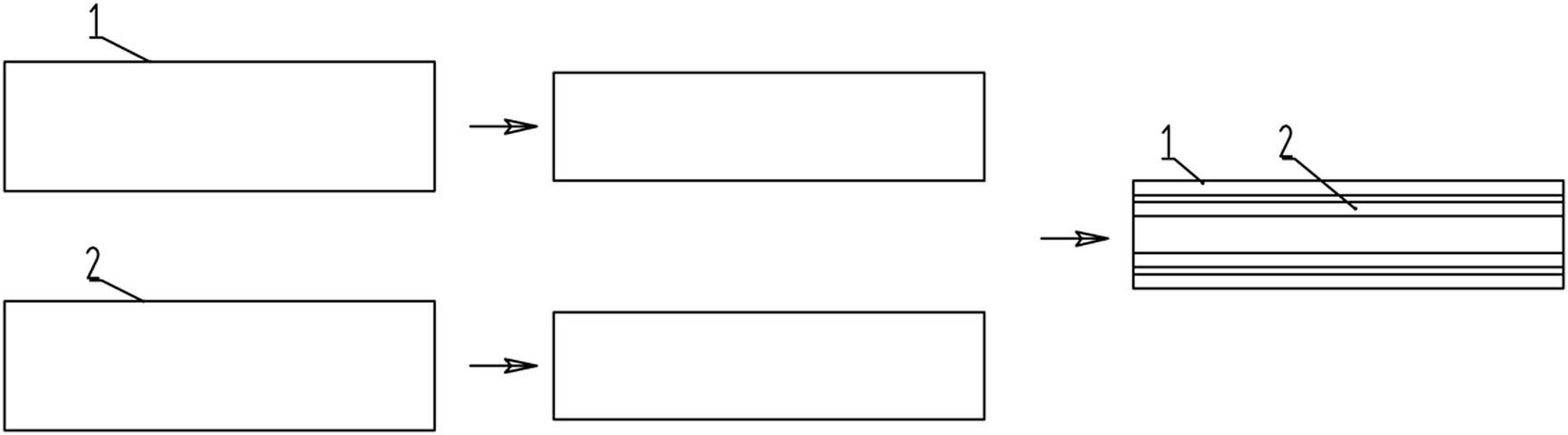

[0025] A method for preparing a bimetal composite pipe, comprising the following steps:

[0026] 1) The outer tube 1 and the inner tube 2 are cold-drawn after surface treatment, and the gap between the inner wall of the outer tube 1 and the outer wall of the inner tube 2 is 2-5 mm;

[0027] 2) Align the inner tube and the outer tube respectively and perform surface treatment, the surface treatment is pickling, cleaning and neutralization, phosphating and saponification;

[0028] 3) The outer tube 1 and the inner tube 2 are combined and cold-drawn, so that the outer tube 1 and the inner tube 2 are tightly combined;

[0029] A bimetal composite pipe is obtained through the above steps.

[0030] In step 3), the amount of wall reduction is controlled to be 6%-24% of the wall thickness during composite cold drawing.

[0031] Optimally, in step 3), the amount of wall reduction is controlled to be 10%-20% of the wall thickness during composite cold drawing.

[0032] For further op...

Embodiment

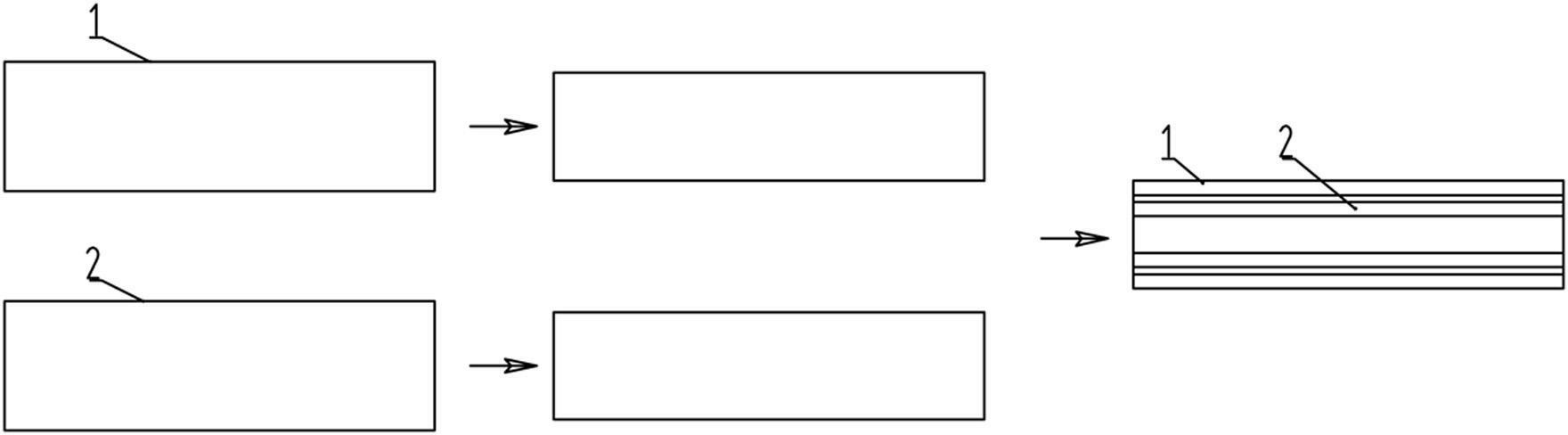

[0039] 1. The raw material specification is 20#Φ140×4×5200mm. Firstly, the surface treatment (pickling—cleaning and neutralization—phosphating—saponification) is carried out, and then the size specification is Φ135×2.5×8200mm through cold extrusion and cold drawing of the inner and outer molds. The precision tube is used as the outer tube 1.

[0040] 2. The specification of the raw material is 45Mn2Φ127×4×6000 mm. After surface treatment and cold drawing, a precision tube with a size of Φ127×2.5×8200 mm can be used as the inner tube 2 .

[0041] 3. Straighten and surface treat the inner and outer pipes respectively;

[0042] 4. Place the straightened 45Mn2 inner tube in the inner hole of the 20# outer tube and align it. At the same time, after compound cold drawing, the inner tube and the outer tube are combined into one, tightly combined without gaps, and the size after cold drawing and compounding is φ133×4.5 ×8200mm, the length dimension is the size after removing the clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com