Redundant high-current power cable assembly and assembly method thereof

A high-current power supply and cable assembly technology, which is applied in the manufacture of insulated cables, electrical components, cables/conductors, etc., can solve the problems of increasing cable leakage current, increasing cable heating, difficult transportation and installation, and ensuring safe and reliable use. , increase the overcurrent, the effect of small effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

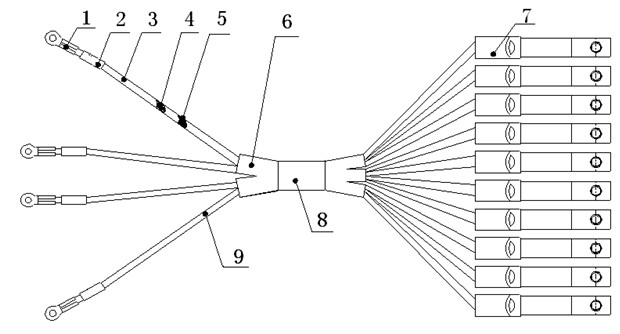

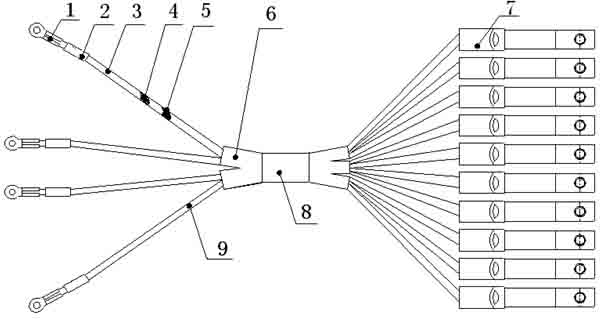

[0010] Control attached figure 1 , its structure is a cable conductor trunk harness 8 which is composed of several layers of cable conductor branch basic harnesses, and a molded shrink sleeve 6 is placed at the bifurcation. One end of each layer of cable conductor branch basic harness 9 is the A terminal 1, and the A terminal 1 cover mark 2, the other end of each layer of cable conductor branch basic wiring harness 9 is B terminal 7.

[0011] The basic wiring harness of the cable conductor branch and the main wiring harness of the cable conductor are wrapped with two layers of PTFE tapes, and the wrapping direction of the two layers of PTFE tape is opposite; the basic wiring harness of the cable conductor branch and the main wiring harness of the cable conductor are DR-25 Casing 3.

[0012] Twisted 27 monofilament silver-plated copper cable conductors with a diameter of 0.1mm into 0.212mm with a stranding machine 2 The wire harness, and then 19 pieces of 0.212mm 2 Use a twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com