Steel sheet, surface-treated steel sheet, and manufacturing method of steel sheet and surface-treated steel sheet

A technology for surface treatment of steel plates and manufacturing methods, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve problems such as inability to cast continuously, and achieve excellent bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

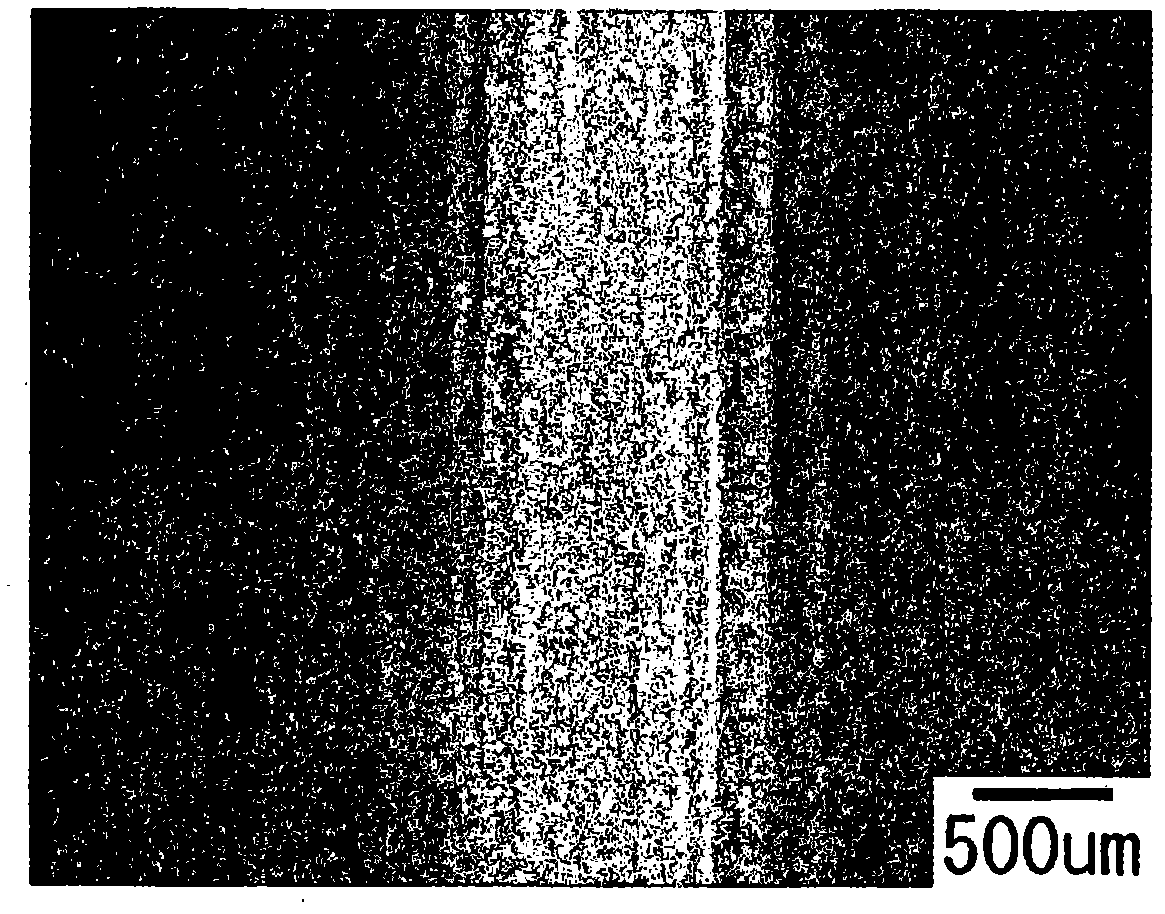

Image

Examples

Embodiment 1

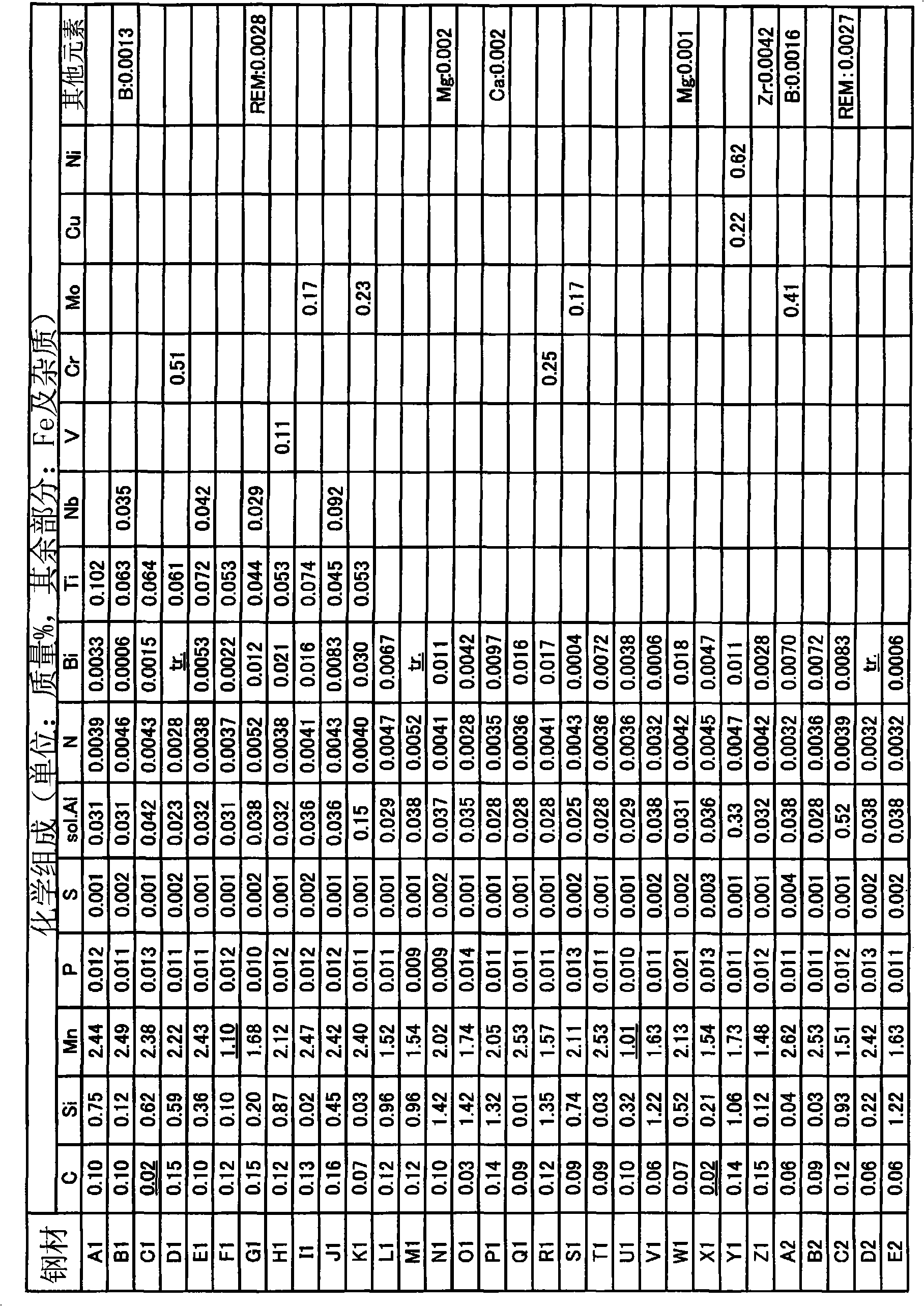

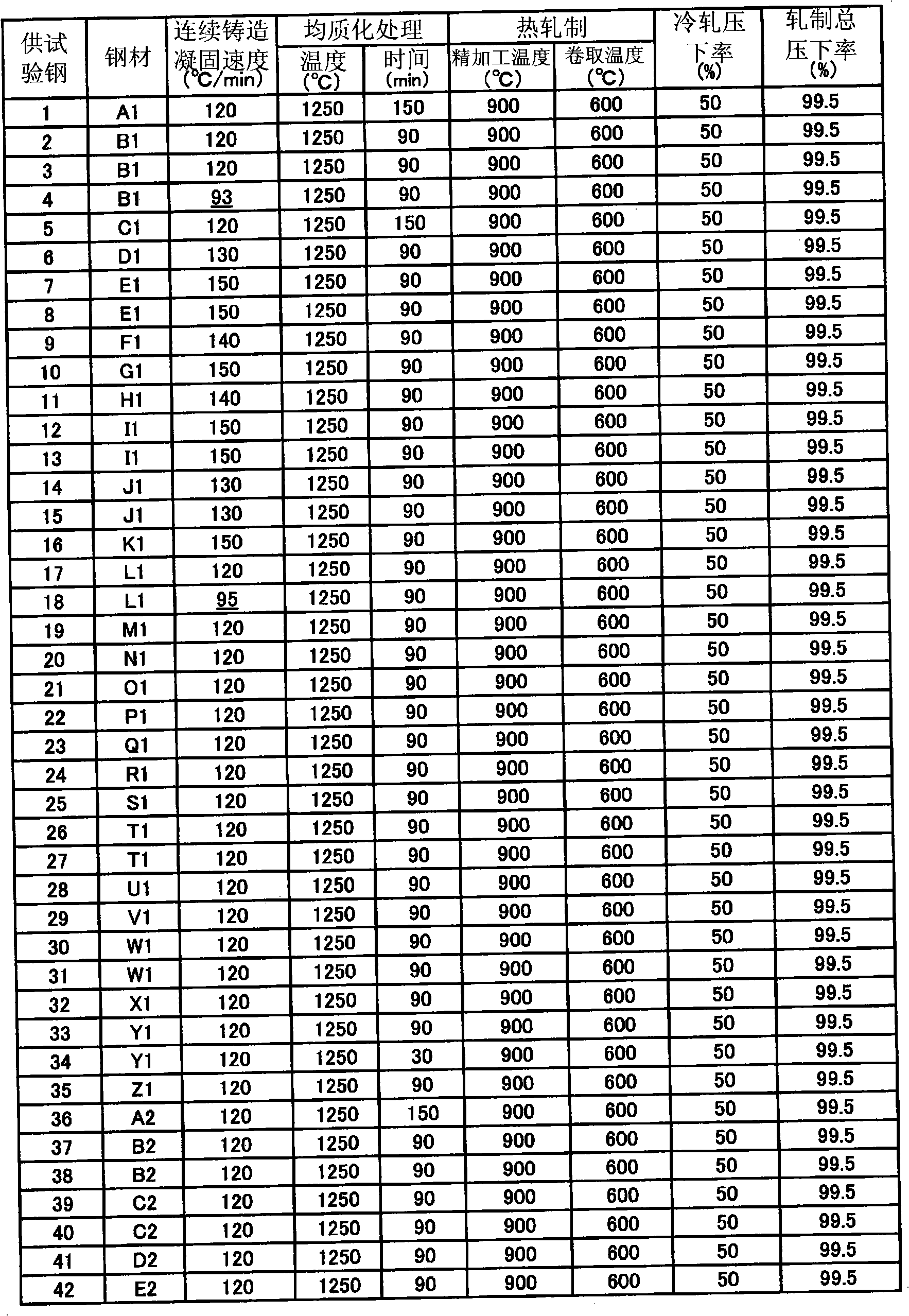

[0108] Steels having the chemical compositions shown in Table 1 were melted using a converter. Next, continuous casting was performed under conditions such that the solidification rate at a position at a depth of 10 mm from the surface of the slab was as shown in Table 2, to produce a slab with a thickness of 245 mm.

[0109] The steel slabs were hot-rolled under the conditions shown in Table 2, pickled thereafter, and then cold-rolled under the conditions shown in Table 2 to obtain cold-rolled steel sheets with a thickness of 1.2 mm.

[0110] Table 1

[0111]

[0112] Table 2

[0113]

[0114] Test pieces for heat treatment were collected from the obtained cold-rolled steel sheets, and heat treatment corresponding to the heating curve of a continuous annealing facility or a continuous hot-dip galvanizing facility was performed as shown in Table 3.

[0115] table 3

[0116]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com