Active cylinder

A technology of active cylinder and casing, which is applied in the field of hydraulic system of clutch system or brake operating system, can solve the problems of cumbersome design of assembly or disassembly, labor-intensive manufacturing, pressing time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

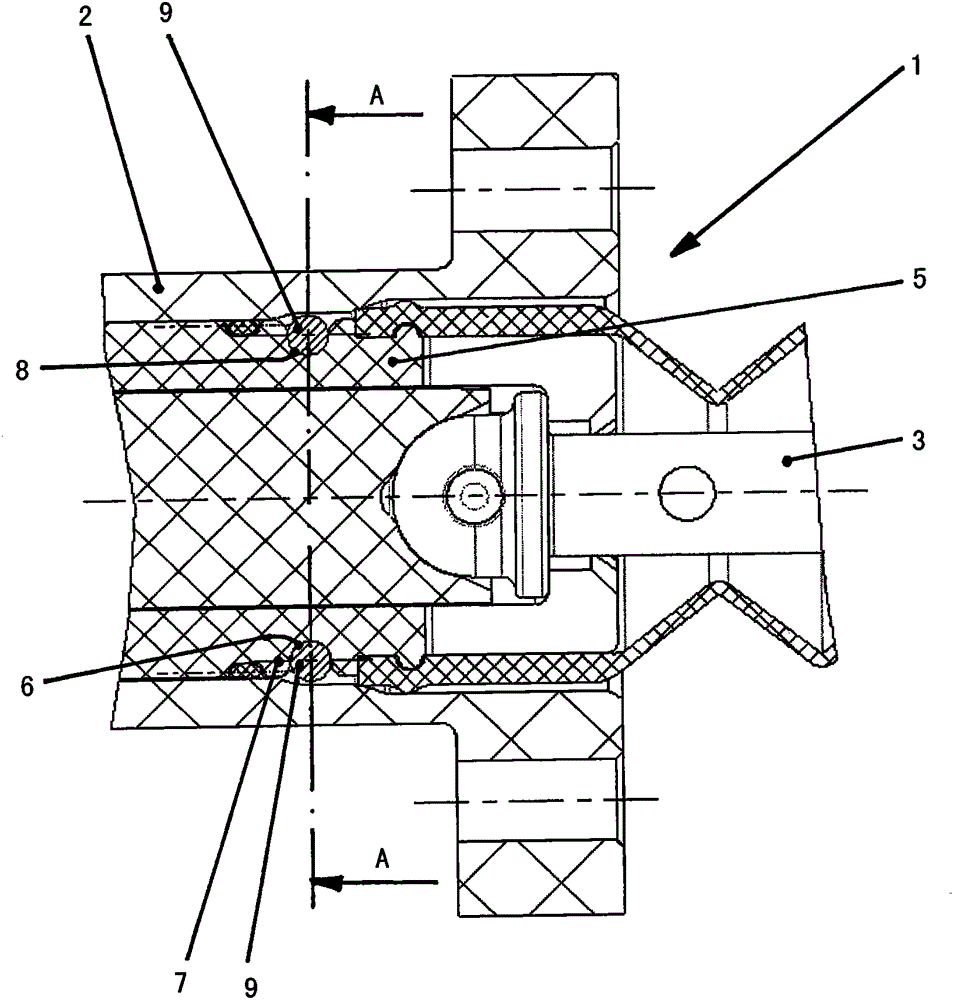

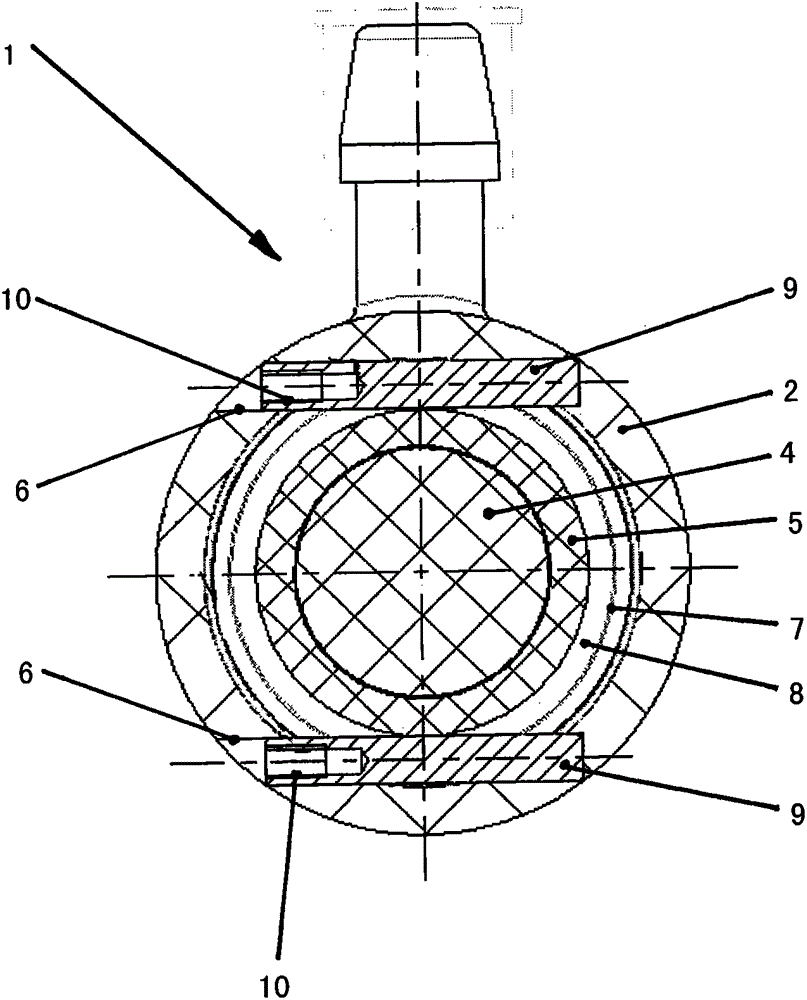

[0014] figure 1 The middle represents the active cylinder 1, which basically consists of a cylindrical housing 2, a piston 4 arranged axially movably in the housing, containing a piston rod 3, and a cover 5 for the housing 2 Composed, the piston defines a pressure chamber filled with hydraulic fluid.

[0015] In order to axially fix the cover 5 on the housing 2, the housing 2 is provided with two transverse bores 6 facing each other, which are each aligned with a recess 8 provided in the outer surface 7 of the cover 5, wherein, in the corresponding transverse direction Pins 9 are provided in the holes 6 and in the recesses 8 . In this case, the transverse bore 6 can be designed as a blind hole or a through hole (not shown), and the pin 9 can be designed as a cylindrical pin or a conical pin (not shown).

[0016] The pin contains an internal thread 10 at its end facing the open transverse bore 6 , which simplifies the removal of the pin 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com