Machine Vision System for Real-time Grain Inspection and Grading

A machine vision system and real-time detection technology, applied in sorting and other directions, can solve the problems of low efficiency, high labor intensity, poor accuracy, etc., and achieve the effect of optimizing resource allocation and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

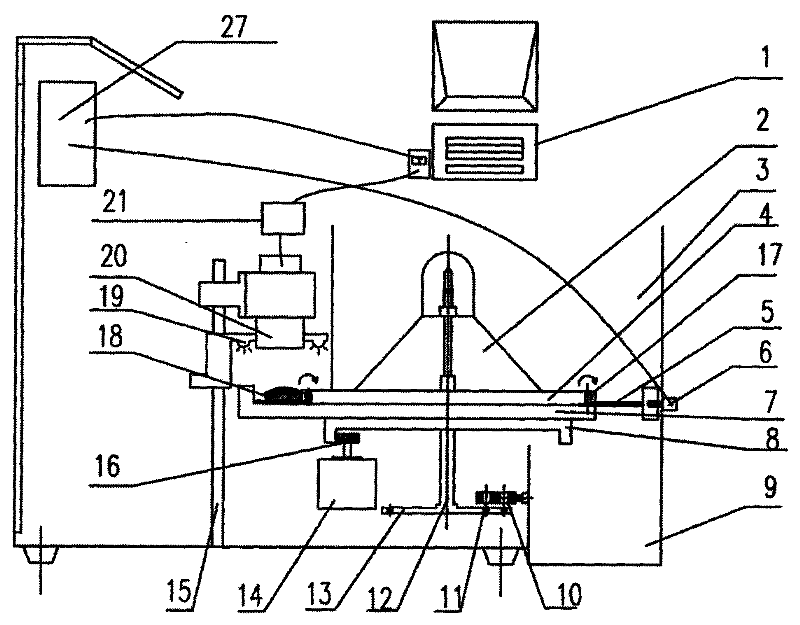

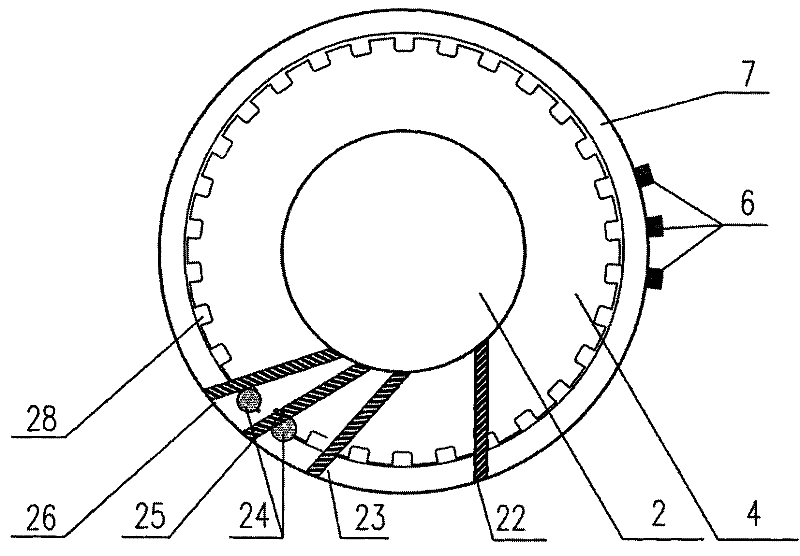

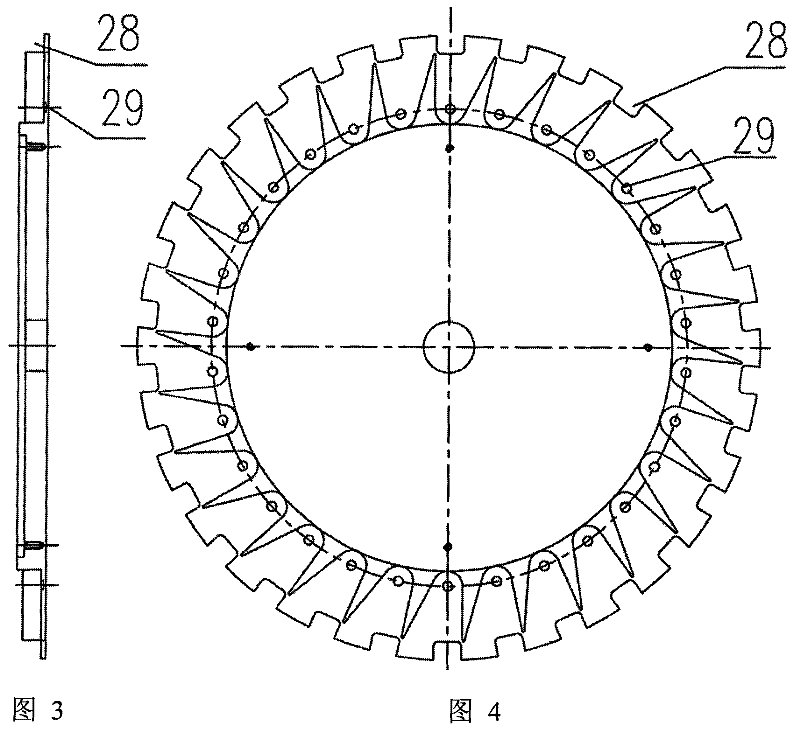

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 Shown, the present invention it comprises power and transmission mechanism, computer vision identification mechanism, single granulation device and automatic grading mechanism; Wherein:

[0026] 1) Power and transmission mechanism: including stepping motor 14, driving gear 16 on the motor, internal gear 8, annular frame 7 and central shaft 12; stepping motor 14 meshes with internal gear 8 through driving gear 16 on its shaft, The internal gear 8 is installed on the lower end surface of the annular frame 7, and the internal gear 8 and the annular frame 7 are coaxially installed on the central shaft 12;

[0027] 2) Computer vision recognition mechanism: including camera 20, acquisition card 21, ring light source 19, bracket 15, computer 1, position sensor 10, positioning sensor 11, posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com