Plugging device and method for powder clearing hole of selective laser melting forming wing rudder structure

A technology of laser selective melting and plugging device, applied in the direction of improving process efficiency, improving energy efficiency, additive manufacturing, etc. Improve the level of automation, high-quality plugging, and achieve the effect of automatic high-efficiency plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

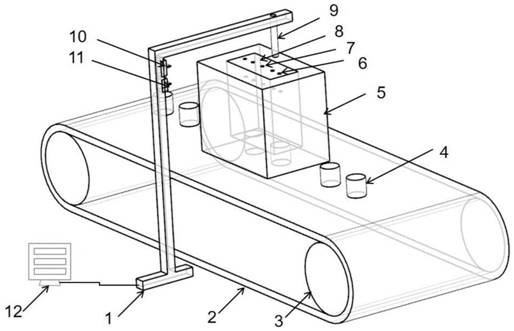

[0032] like Figure 1-Figure 2 As shown, the present invention provides a plugging device for cleaning powder hole of a wing rudder structure formed by laser selective melting, including a plugging bracket 1, a transmission belt 2 of a transmission module, a pulley 3 of a transmission module, a fixed module 4, and a wing rudder follow-up tooling 5. Wing rudder structure powder cleaning hole 6, plugging test block 7, wing rudder structure 8, blocker 9, position recognition and feedback module 10, quality inspection module 11 and control terminal 12. Wherein, the occlusion bracket 1 is in a "like I-shape", and serves as the load-bearing structure of the occluder 9, the position recogniti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com