Closed self-locking cleaning device of tank

A technology for cleaning devices and tanks, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of operator safety impact, high worker work intensity, large amount of steam waste, etc. Effects of pollution, saving steam usage, reducing steam emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

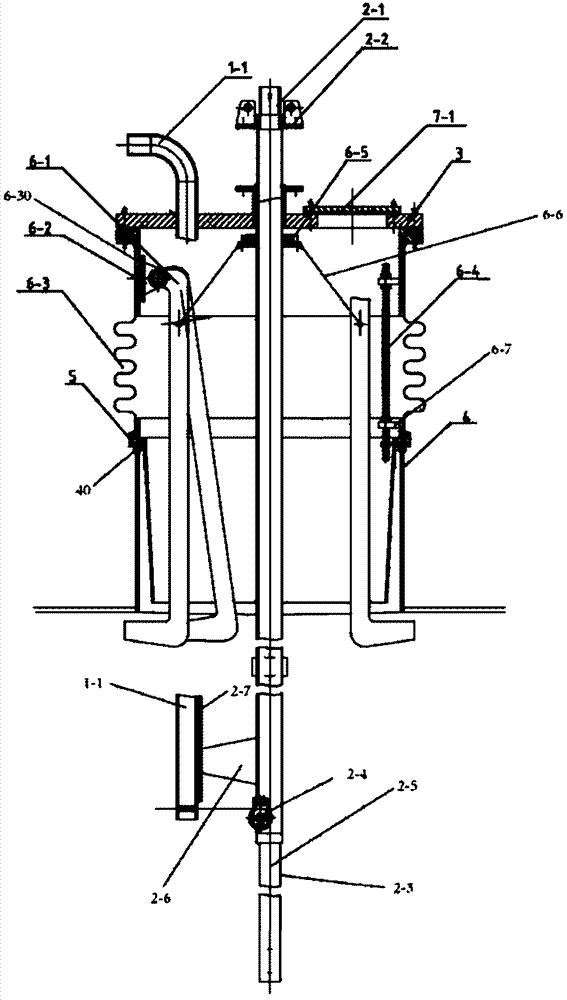

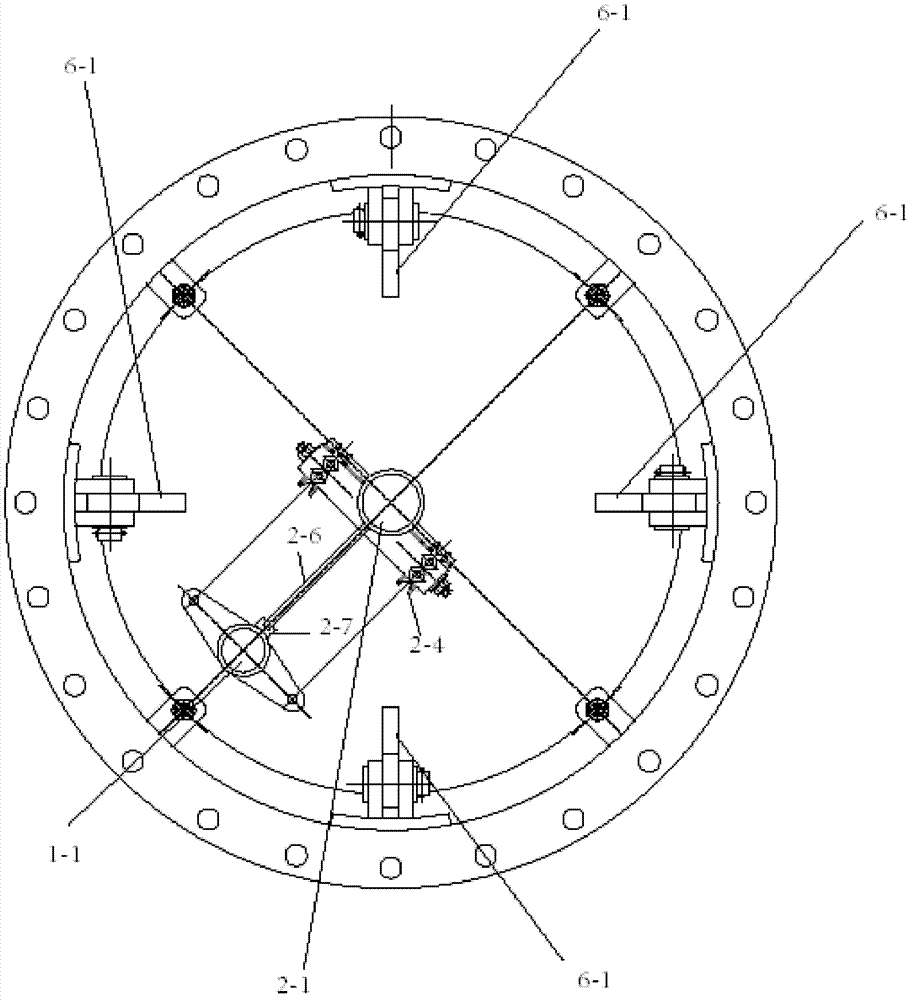

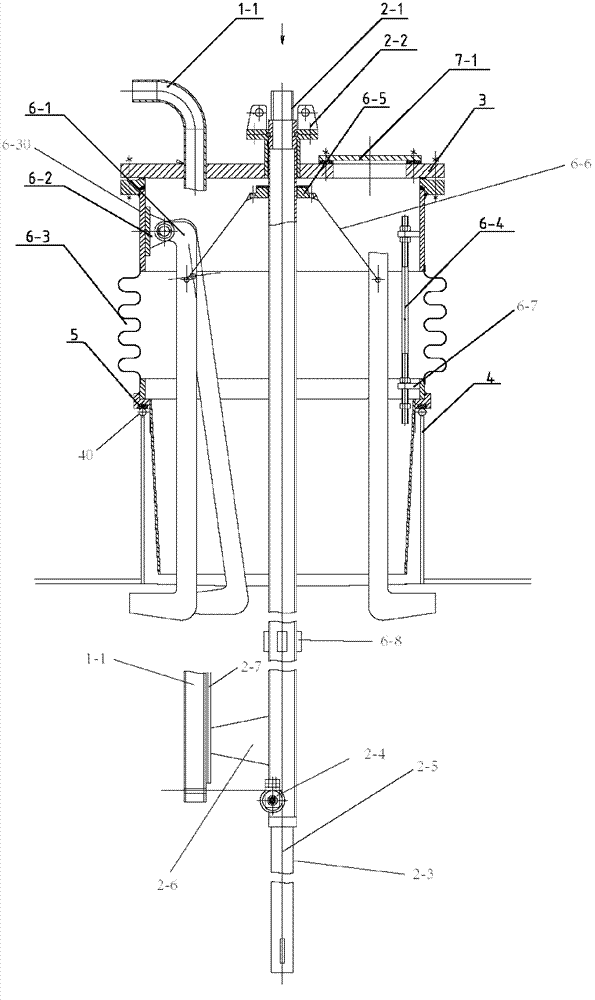

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0034] see figure 1 and figure 2 , which shows a preferred embodiment of a closed self-locking cleaning device for a tank of the present invention, including a rigid section 6-30 divided into at least two sections and a telescopic section 6 arranged between the adjacent rigid sections 6-30 -3. The present invention may include multiple rigid segments 6-30 and at least one telescopic segment 6-3. In this embodiment, there are two rigid sections 6-30, and a telescopic section 6-3 is arranged between the two rigid sections 6-30. Preferably, the rigid section 6-30 can adopt a metal cylindrical structure, The telescopic section 6-3 can adopt a bellows structure or other telescopic structures, and its material can be metal or non-metal.

[0035] Wherein, the bottom end of the rigid section 6-30 is fitted and airtightly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com