A self-adaptive method for strip laminar cooling temperature

A laminar cooling and self-adaptive technology, applied in temperature control and other directions, can solve problems such as the inability to meet the requirements of temperature control accuracy, achieve the effect of perfecting the self-learning system, solving the difference in cooling conditions, and improving the hit rate of coiling temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

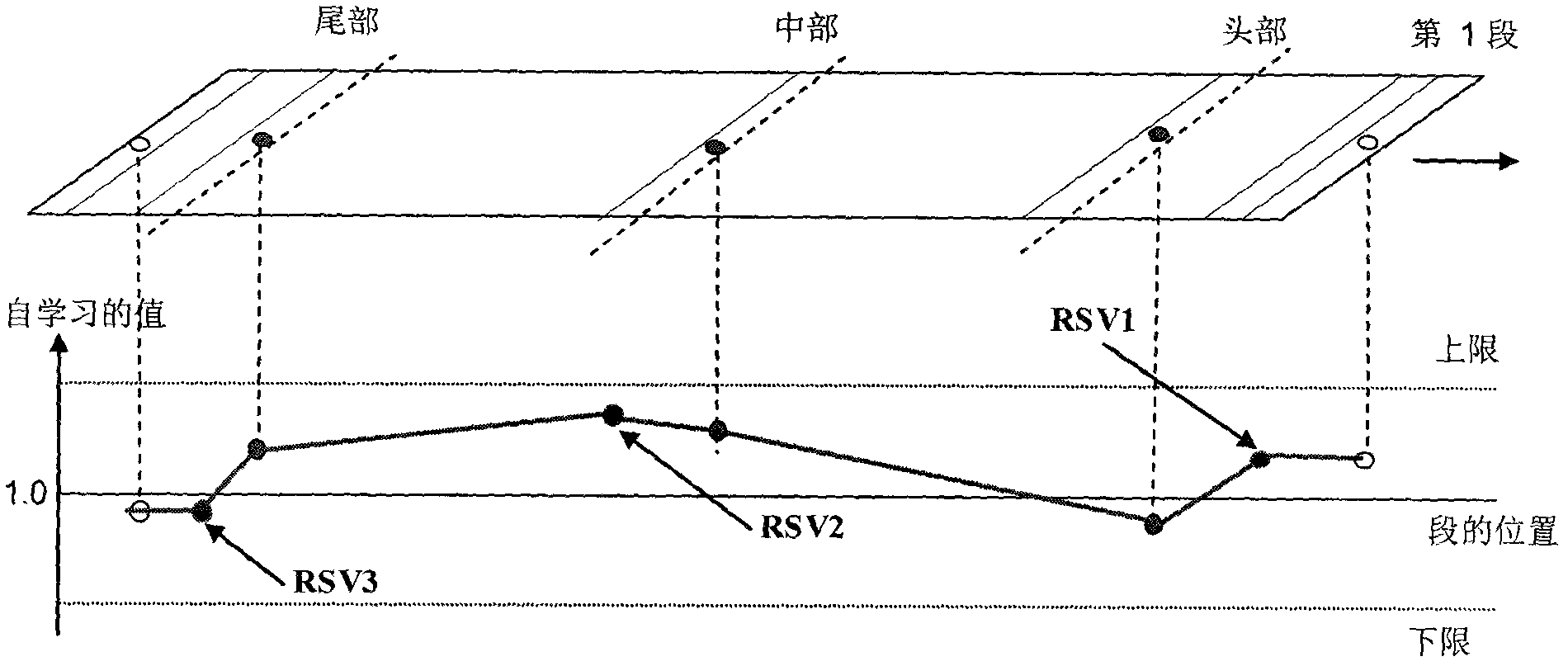

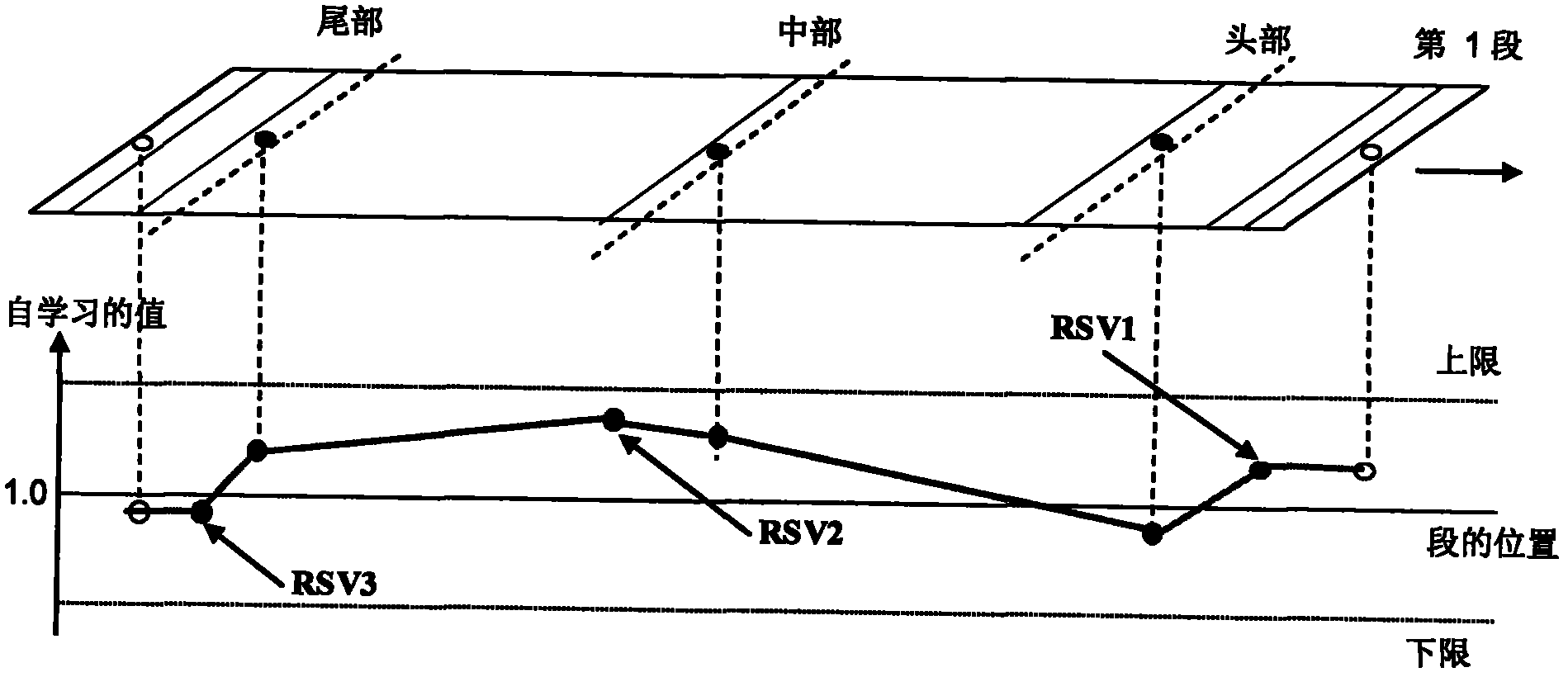

[0008] After finishing rolling and thinning, the strip steel enters the coiler for coiling after laminar flow cooling. When the strip steel changes due to temperature, speed and other conditions, there are great differences in the cooling conditions of the strip steel surface. It is obvious that the temperature control of the full-length strip steel by using only three-point temperature self-study can not solve this difference and cannot meet the temperature control requirements. precision requirements. The self-learning system is the adjustment center of the whole control system, and the quality of the self-learning system is related to the control accuracy of the whole system. For this reason, a self-learning control point RSV1, RSV2, RSV3 is added at the head, middle, and tail of the strip. Encrypted six-point self-learning makes the self-learning system more perfect.

[0009] Table 1 shows the definitions of six self-learning point distances for rolled common carbon stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com