Metal Seamless Pipe Fitting Spinning Forming Device

A seamless pipe fitting and spinning forming technology is applied in the field of seamless metal pipe fitting processing machinery, which can solve the problems of ineffective replacement of seams, complex equipment structure and high production cost, and achieves compact structure, advanced processing technology and high production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

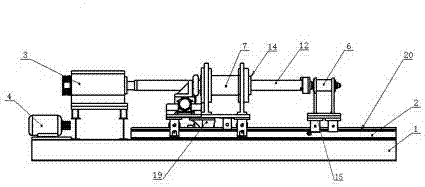

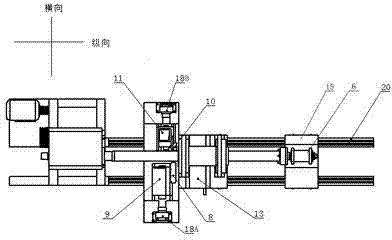

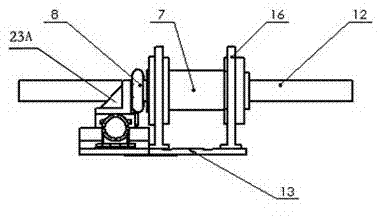

[0028] Such as figure 1 with 2 As shown, the metal seamless pipe fitting spinning forming device includes a bed 1, and a headstock 3 is fixedly arranged on the left side of the bed 1. The headstock 3 is driven by a spindle motor 4. Driven by the spindle motor 4, the spindle in the headstock 3 able to turn. A guide rail 2 is fixedly arranged on the right side of the bed 1, and a rack 20 is arranged on the guide rail 2. On the guide rail 2, a large carriage 13 and a tailstock carriage 15 are movably arranged successively from left to right. The bottom of the large carriage 13 is provided with a gear, which can mesh with the rack 20 . Large plank 13 is driven by drive motor through large plank reducer 19. Tailstock carriage 15 also can move on guide rail 2. The auxiliary axle box 6 is fixedly arranged on the tailstock carriage 15, and the auxiliary axle box 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com