A grinding method of high-precision permanent magnet seat

A permanent magnet and high-precision technology, applied in the field of grinding, can solve the problems of poor precision and difficult measurement, and achieve the effects of simplifying alignment and measuring times, good consistency, and improving processing efficiency and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

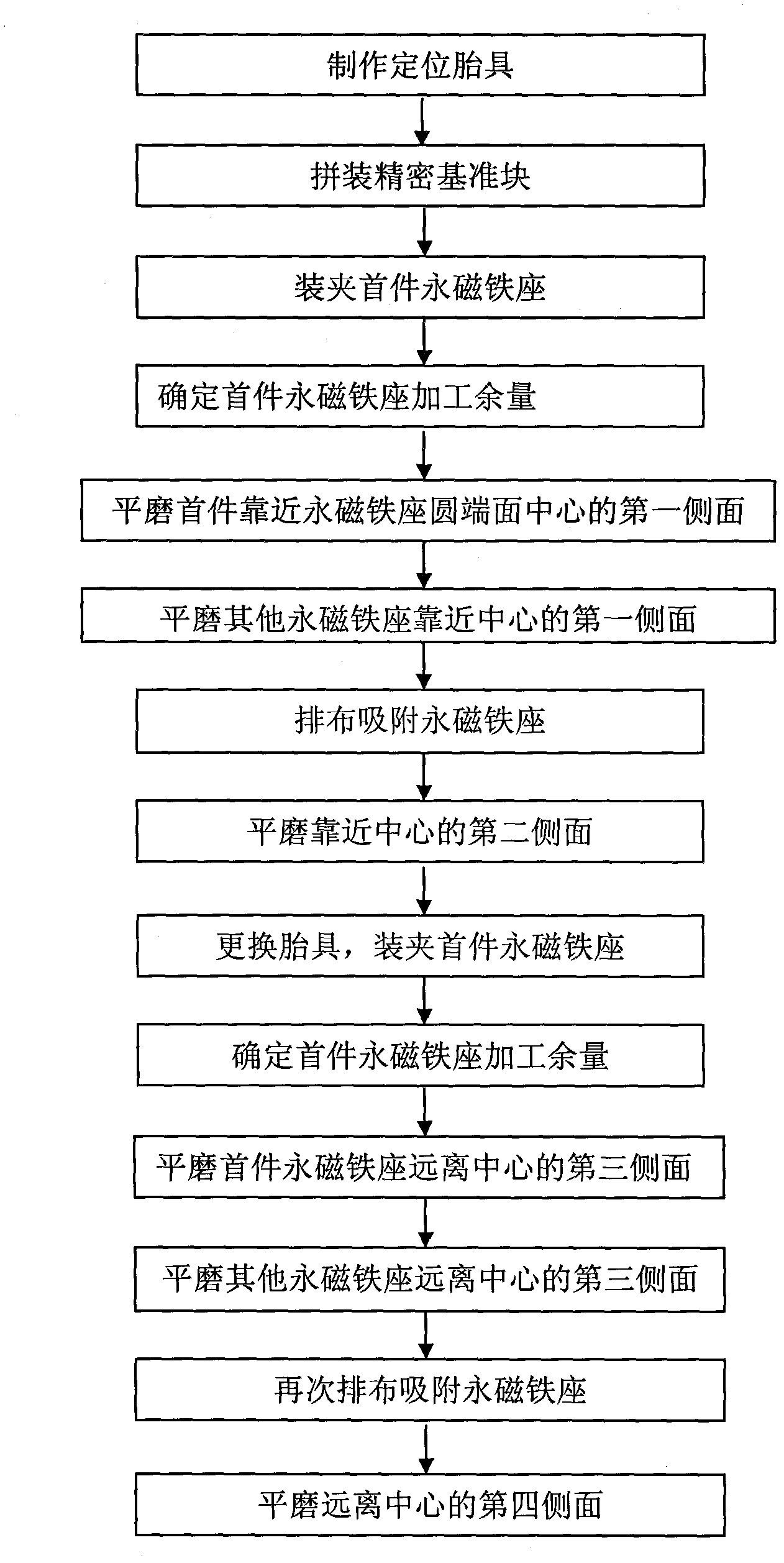

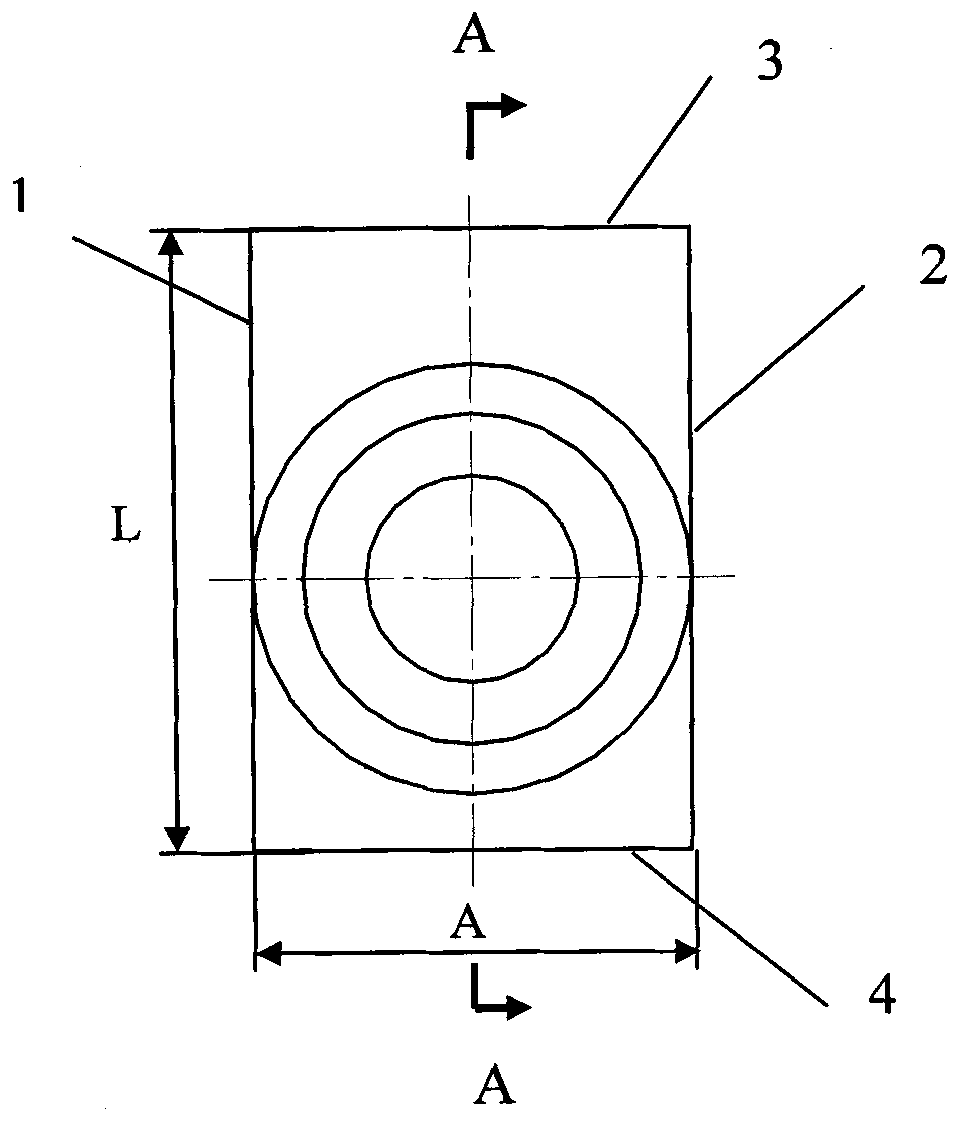

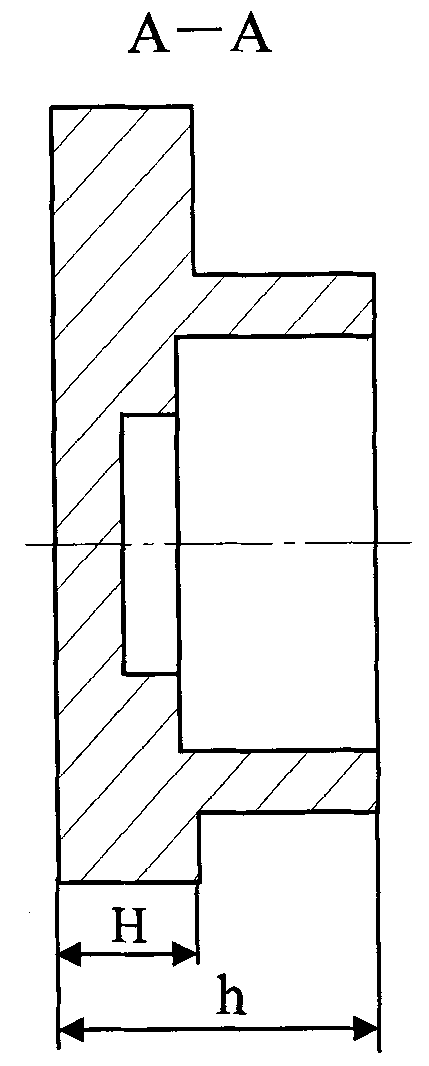

[0060] see figure 2 and image 3 , figure 2 It is a front view of a certain accelerometer permanent magnet seat part in a preferred embodiment of the processing method of the accelerometer permanent magnet seat part of the present invention, image 3 yes figure 2 left view of . In this embodiment, one end of the part is a circular platform, and the other end is a square platform. part size, height Director Fang width Thickness H=3.8mm, and the perpendicularity between the first side 1 and the third side 3 of the square platform is required to be φ0.02, the reference plane of the third side 3 and the center of the circular platform are 8.5±0.01mm, the reference of the first side 1 and the circular platform The center size is 6.75mm. In order to ensure the size and position accuracy required by these designs, it is necessary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Verticality | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com