Preparation method for fibrinogen

A fibrinogen and sediment technology, applied in the field of pharmaceutical bioengineering, can solve problems such as inconvenience of use, increase the content of toxins such as pyrogen, and prolong the production cycle, so as to achieve the protection of biological activity, shorten the reconstitution time, and reduce the possibility of sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

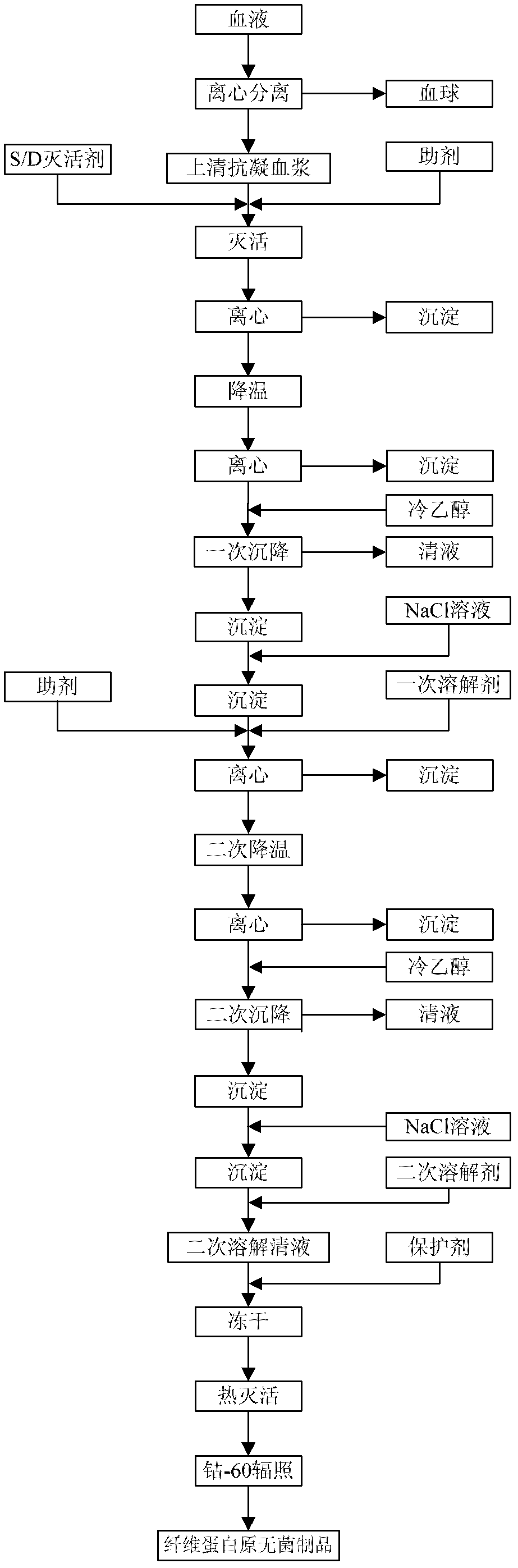

Method used

Image

Examples

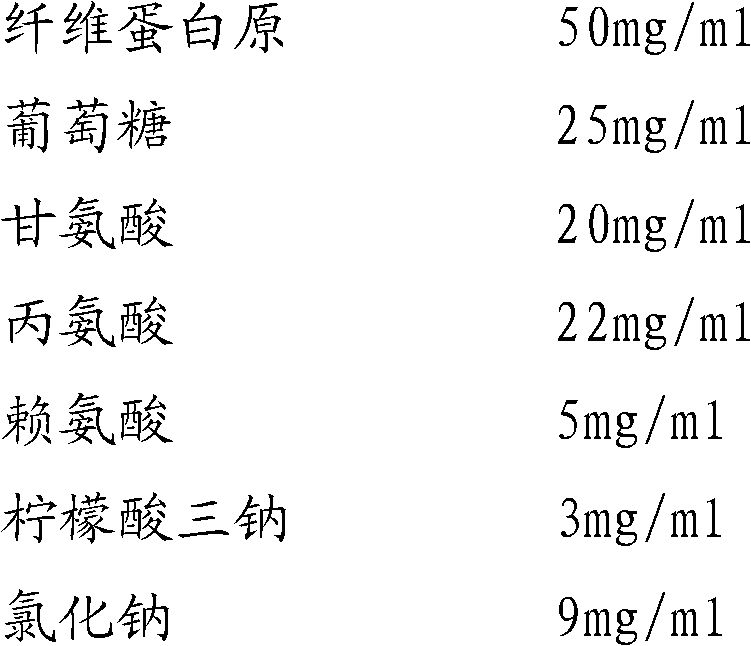

Embodiment 1

[0060] All operations in the process of Example 1 are carried out in a sterile 10,000-level purification area, wherein subpackaging and freeze-drying operations are all carried out in a local 100-level purification area, and the operations performed all meet the operating requirements of the clean area. The production specification is 2.5ml.

[0061] (1) Get 10000ml of aseptically collected pig blood;

[0062] (2) Centrifuge, take supernatant anticoagulant plasma 5500ml;

[0063] (3) Add 2.5% w / v glucose and 0.38% w / v trisodium citrate to the supernatant anticoagulated plasma obtained in step (2) as auxiliary agents, then add 0.3% w / v tributyl phosphate and 1% w / v Tween-80 was used as a virus inactivating agent, and the virus was inactivated at 25°C for 6 hours;

[0064] Centrifuge the inactivated plasma, discard the precipitate, and take the supernatant;

[0065] (4) Primary sedimentation: Pre-cool the clear liquid obtained through step (3) to 0-4°C, carry out centrifugati...

Embodiment 2

[0077] All operations in the process of Example 2 are carried out in a sterile ten thousand-level purification area, wherein subpackaging and freeze-drying operations are all carried out in a local one-hundred-level purification area, and the operations performed all meet the operating requirements of the clean area. The production specification is 2.5ml.

[0078] (1) Get 150000ml of aseptically collected pig blood;

[0079] (2) Centrifuge and take 82000ml of supernatant anticoagulated plasma;

[0080] (3) Add 2% w / v glycine to the supernatant anticoagulated plasma obtained in step (2) as an auxiliary agent, then add 0.3% w / v tributyl phosphate and 1% w / v Tween-80 as a virus Inactivator, carry out virus inactivation at 25°C for 6 hours;

[0081] Centrifuge the inactivated plasma, discard the precipitate, and take the supernatant;

[0082] (4) Primary sedimentation: pre-cooling the clear liquid obtained through step (3) to 0-4°C, centrifuging, discarding the precipitate, tak...

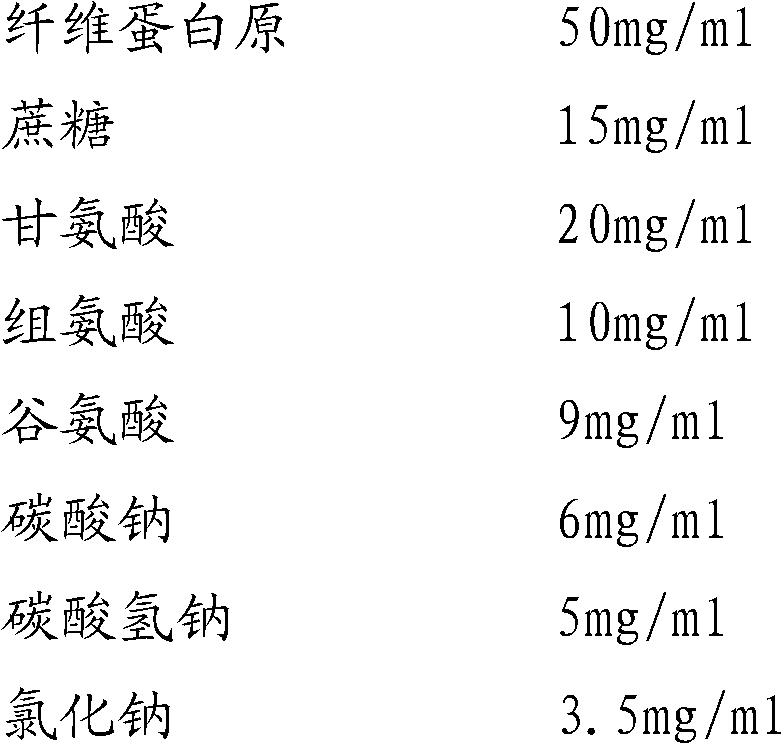

Embodiment 3

[0094] All operations of the process in Example 3 are carried out in a ten thousand-level purification area, wherein subpackaging and freeze-drying operations are all carried out in a local one-hundred-level purification area, and the operations performed all meet the operating requirements of the clean area. The production specification is 2.5ml.

[0095] (1) Get 50000ml of aseptically collected pig blood;

[0096] (2) Centrifuge and get supernatant anticoagulated plasma 26000ml;

[0097] (3) Add 0.3% w / v tributyl phosphate and 1% w / v Tween-80 to the supernatant anticoagulated plasma obtained in step (2) as a virus inactivator, and carry out virus inactivation at 25° C. Hour;

[0098] Centrifuge the inactivated plasma, discard the precipitate, and take the supernatant;

[0099] (4) Primary sedimentation: Pre-cooling the clear liquid obtained through step (3) to 0~4° C., centrifuging, discarding the precipitate, getting the clear liquid and adding cold ethanol (95% v / v) 2340m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com