Method for Improving Magnetic Properties of Cold Rolled Non-Oriented Silicon Steel

A technology of oriented silicon steel and magnetism, which is applied in the field of cold-rolled silicon steel production, can solve problems such as different control parameters, magnetic deterioration, and hindrance to decarburization, and achieve low cost of coating liquid, improve magnetic properties of finished products, and reduce internal oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with the examples, the finished product free silicon steel of the present invention is further described.

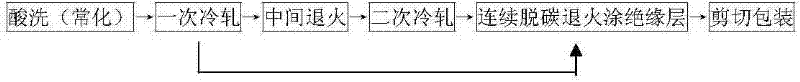

[0028] The present invention improves the magnetic method of cold-rolled non-oriented silicon steel, and the method steps are as follows: pickling, cold rolling, continuous annealing, in described continuous annealing step, also have the following steps:

[0029] a. Add a set of inorganic salt coating device in the continuous annealing and cleaning system, and the silicon steel strip after cold rolling is evenly coated with a layer of inorganic salt solution by the inorganic salt coating device;

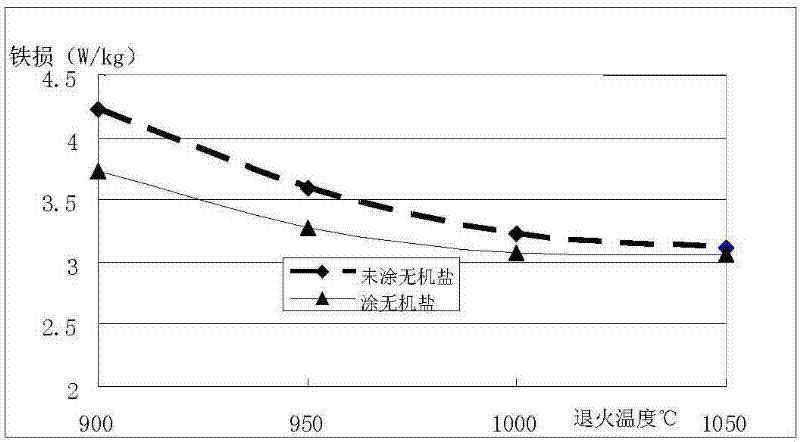

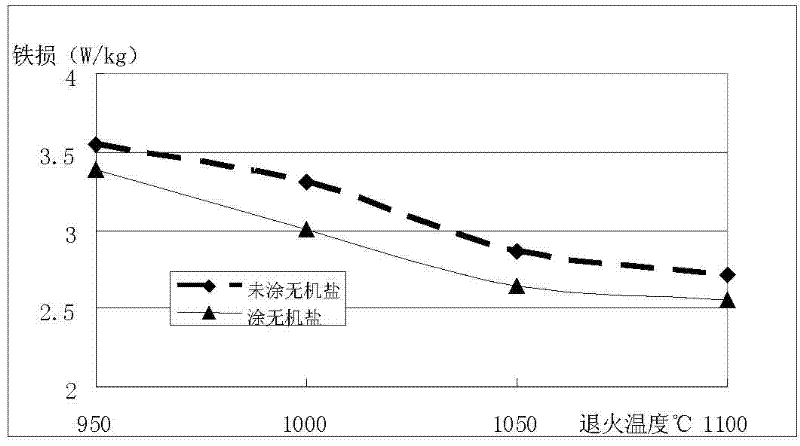

[0030] B, the weight percentage of described inorganic salt solution is: K 2 CO 3 0.5~5.0%, NaCl 0.5~2%, MgO 1~8%, the rest is H 2 O; For different numerical selections, the experimental results are shown in Table 1:

[0031] Table I

[0032]

[0033] c, the coating quantity of described inorganic salt solution is: 1g~50 g / m 3 ;

[0034]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com