A box body with a left and right compartment structure for a vacuum cleaner

A vacuuming vehicle, left and right technology, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of high processing and production costs, increasing the resistance of the pipe network, and reducing the vacuuming effect of the whole vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

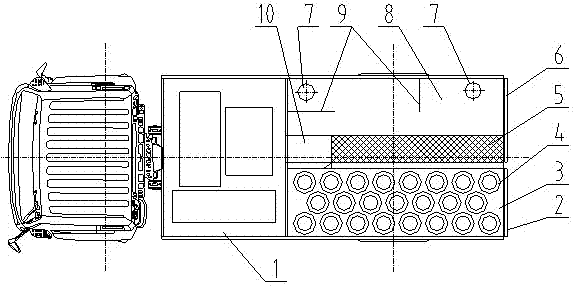

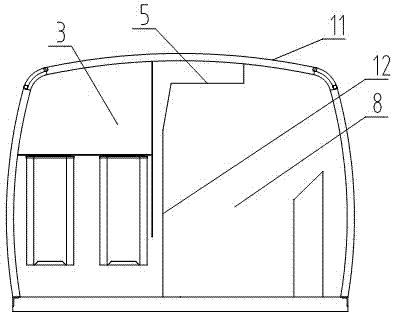

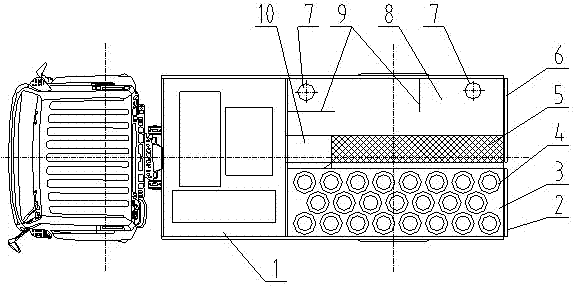

[0009] like figure 1 As shown, it mainly includes: power compartment 1, filter silo sealing door 2, filter silo 3, filter cartridge 4, overhead filter 5, garbage compartment sealing door 6, suction port duct 7, garbage compartment 8, diversion Plate 9; it is characterized in that: the rear box is separated from left to right with a partition, and the connection method is: the partition partition 12 separates the box into left and right filter silos 3 and garbage warehouses 8, and the top filter 5 is connected The filter silo 3, the garbage bin 8, and the suction port duct 7 are installed on the right side of the garbage bin 8. During operation, the garbage enters the garbage bin 8 through the dust suction port duct 7 with the air flow, and after gravity sedimentation under the action of the deflector 9, the air flow enters the filter silo 3 through the overhead filter screen 5, and the overhead filter screen 5 prevents The lightly thrown garbage enters the filter silo 3 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com