A new type of fireproof insulation material and its manufacturing process

A technology for fire prevention and heat preservation and manufacturing process, which is applied in the directions of heat preservation, fire prevention, building components, etc., can solve problems such as unsatisfactory fire prevention or environmental protection, and achieve the effect of enhancing heat preservation and heat insulation indicators, ensuring fire safety, and preventing burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Examples of the present invention are given below to further describe in detail, but the scope of the present invention is not limited thereto.

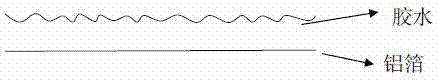

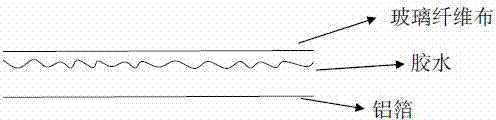

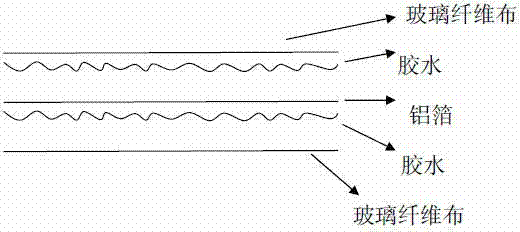

[0027] A: first as figure 1 Apply fireproof glue evenly on the aluminum foil, such as figure 2 Then cover the glass fiber cloth on the aluminum foil coated with fireproof glue to make a single-sided aluminum foil composite glass fiber cloth; image 3 As shown, the fireproof glue is evenly coated on the other side of the aluminum foil, and then the glass fiber cloth is covered on the aluminum foil coated with the fireproof glue to make a double-sided aluminum foil composite glass fiber cloth.

[0028] B: if Figure 4 , the aluminum foil composite glass fiber cloth obtained in step A is folded to form a cavity; the aluminum foil composite glass fiber cloth has certain strength and toughness due to aluminum foil and glass fiber cloth, so it can be shaped by a mold or folded. Said cavity is the space consistent with the size s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com