Concentric pipe wellhead device for exploiting thickened oil through steam assisted gravity drainage

An auxiliary gravity and wellhead device technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve the influence of temperature and pressure testing, can not measure wellbore temperature and pressure in real time, and is not used for testing and other issues to achieve the effect of ensuring safe and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

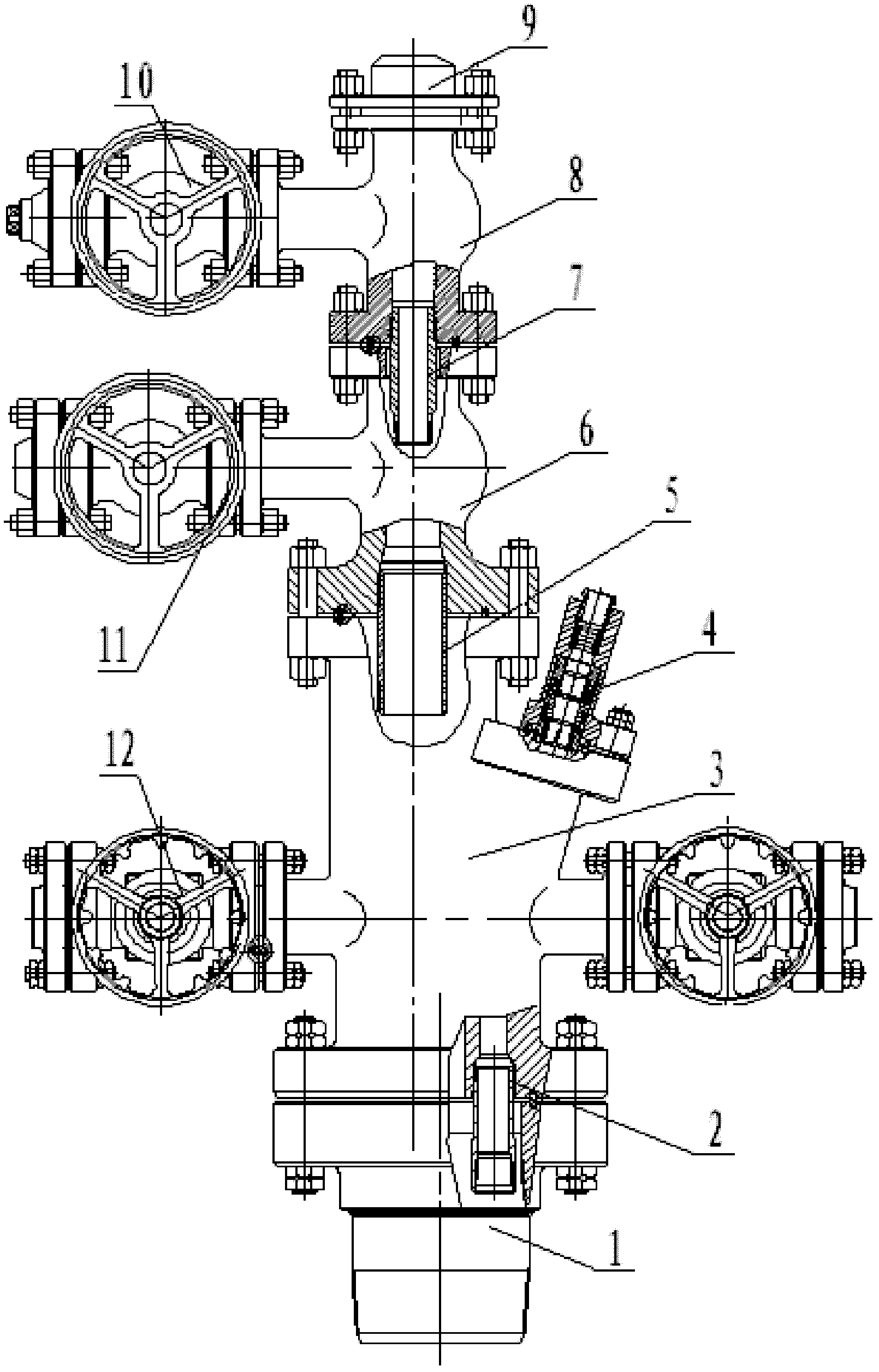

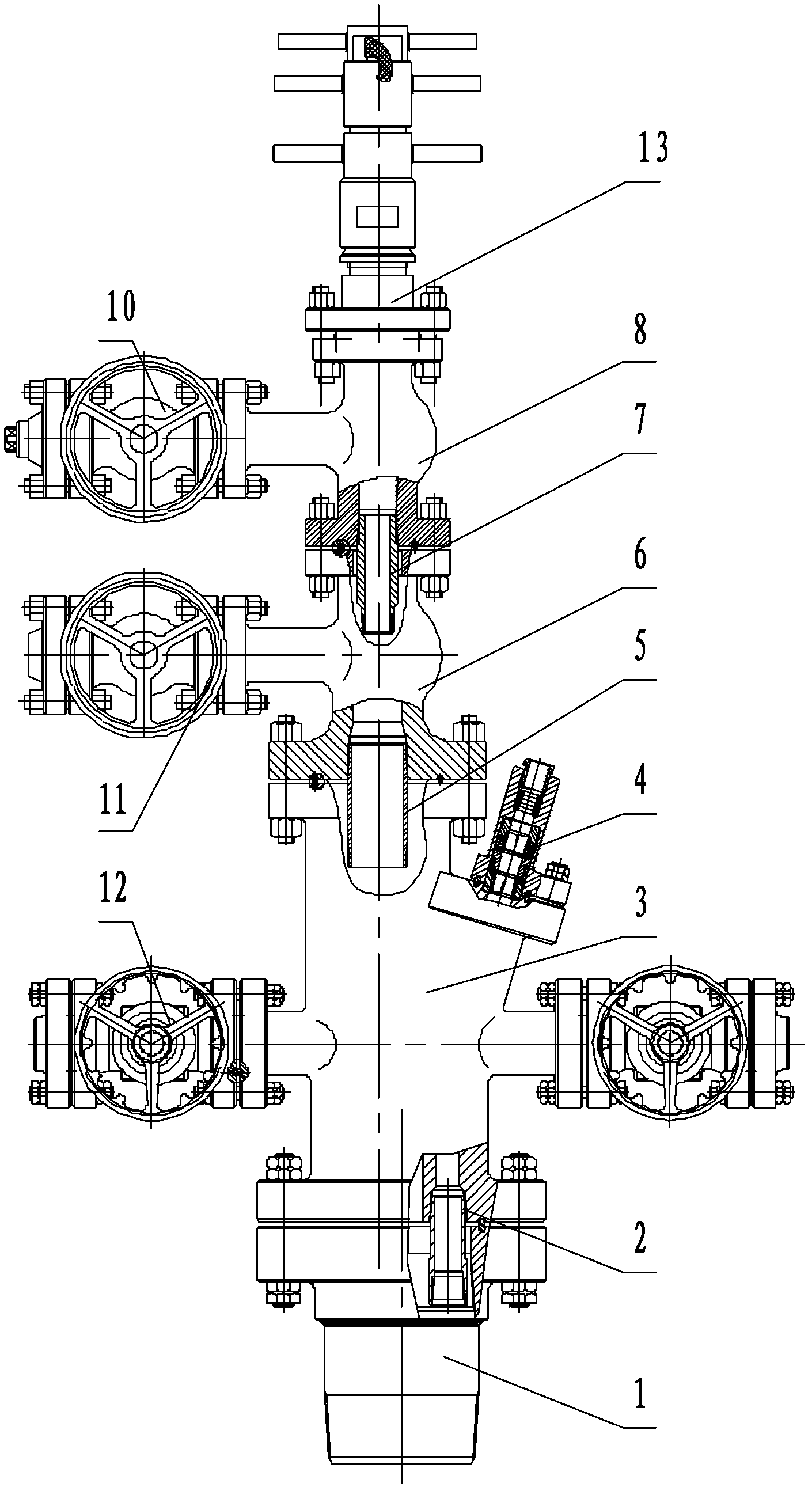

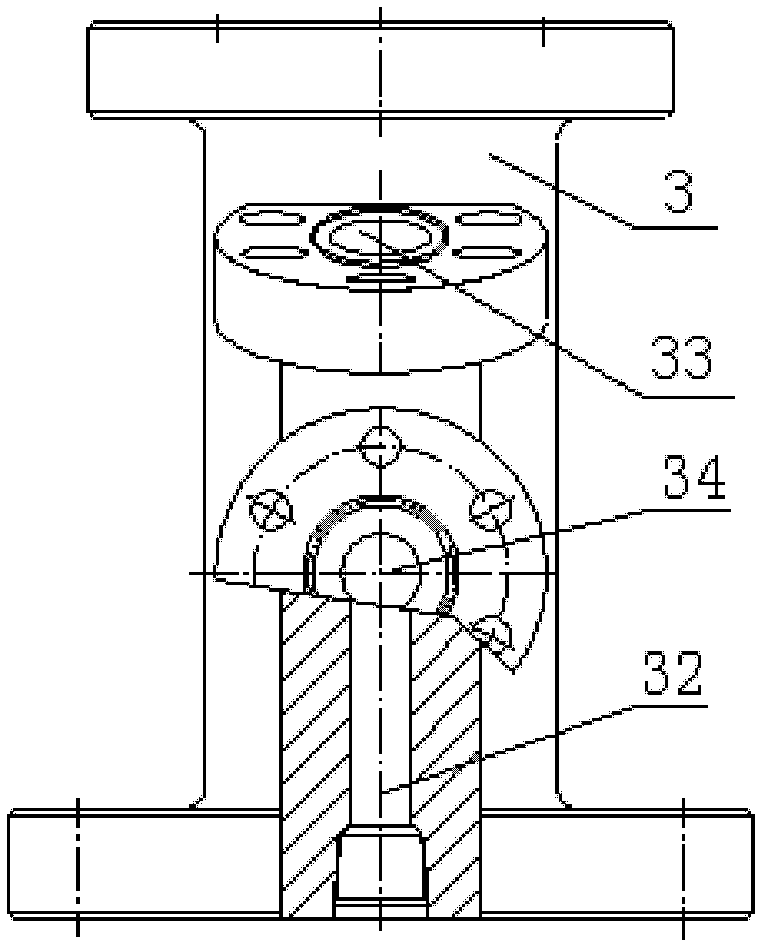

[0029] Embodiment 1: Taking a concentric tube wellhead device for heavy oil recovery by steam-assisted gravity drainage as an example, the present invention will be further described in detail.

[0030] refer to figure 1 . The concentric pipe wellhead device used in steam-assisted gravity drainage to exploit heavy oil is mainly composed of a casing flange nipple 1, a test tubing suspension nipple 2, a large cross 3, a coiled tubing suspension sealing device 4, and an outer tubing suspension Puppet 5, outer pipe small tee 6, inner oil pipe suspension nipple 7, inner pipe small tee 8, wax removal gate valve 9, inner pipe production or steam injection gate valve 10, outer pipe production or steam injection gate valve 11 and casing gate valve 12 composition.

[0031] The lower end of casing flange pup joint 1 has 9 5 / 8 BCSG (outer diameter 244.5mm) (the standard used in China is the national standard of the People's Republic of China "Processing, Measurement and Inspection o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com