Apparatus for measuring foam wet weight gain for low temperature insulation

A low-temperature thermal insulation and measuring device technology, which is applied in the fields of aerospace and refrigeration low-temperature engineering, can solve the problems of moisture absorption and weight gain of foam plastics not involved in low-temperature thermal insulation, and achieves the effects of simple and reliable device structure, simple operation, and convenient disassembly and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

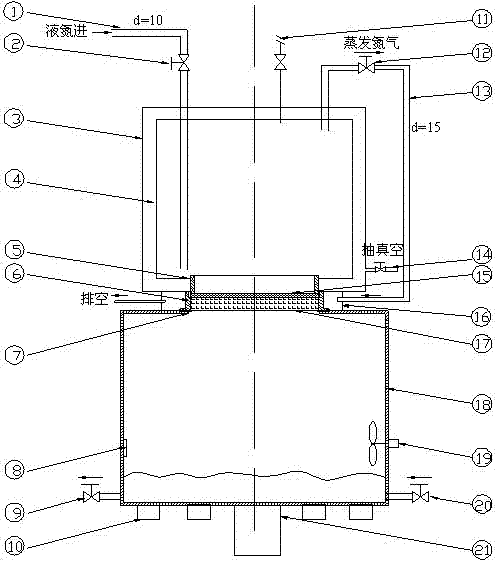

[0016] Such as figure 1 As shown, the foam plastic moisture absorption and weight gain measuring device for low-temperature heat insulation includes a constant temperature and high humidity box 18, a sample cover 6, a liquid nitrogen outer tank 3, a liquid nitrogen inner tank 4, a liquid nitrogen tank 5, and a shroud 16; 18. The sample cover 6, the liquid nitrogen tank 5, the liquid nitrogen outer tank 3, and the liquid nitrogen inner tank 4 are connected in sequence, and the shroud 16 is set on the outside of the sample cover 6; G-10 gasket 7 is arranged in the tank, PTC heating resistor 8 and fan 19 are arranged on the inner wall of constant temperature and high humidity box 18, water inlet system 20 and drainage pipeline 9 are arranged at the bottom of constant temperature and high humidity box 18, The bottom of the box 18 is provided with an ultrasonic generator 10 and a small lifter 21; the sample cover 6 is provided with a foam plastic sample 17 to be tested; the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com