Automatic detection device for pyrotechnics

An automatic detection device and a technology for pyrotechnics, which are used in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., and can solve problems such as large manual tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

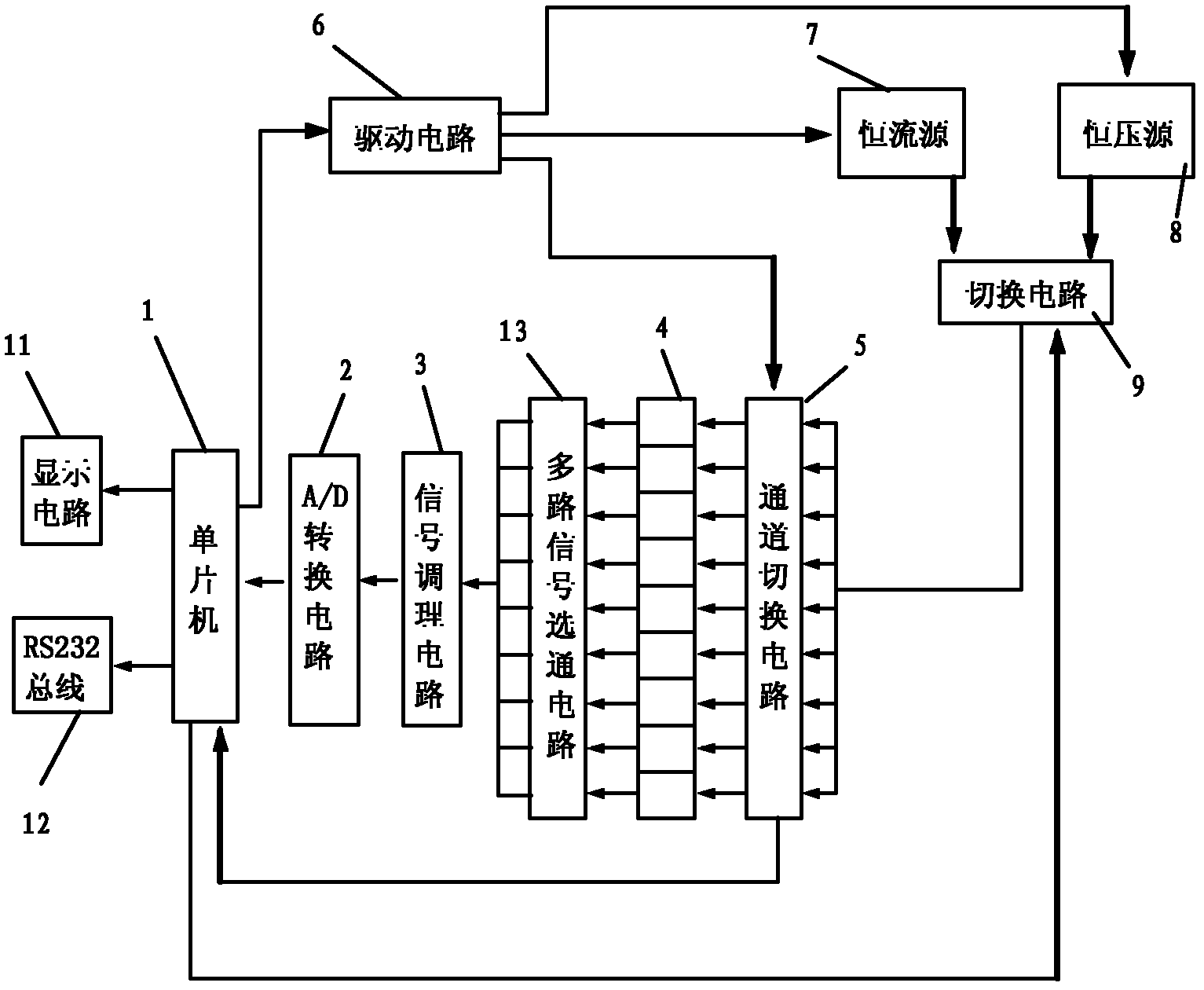

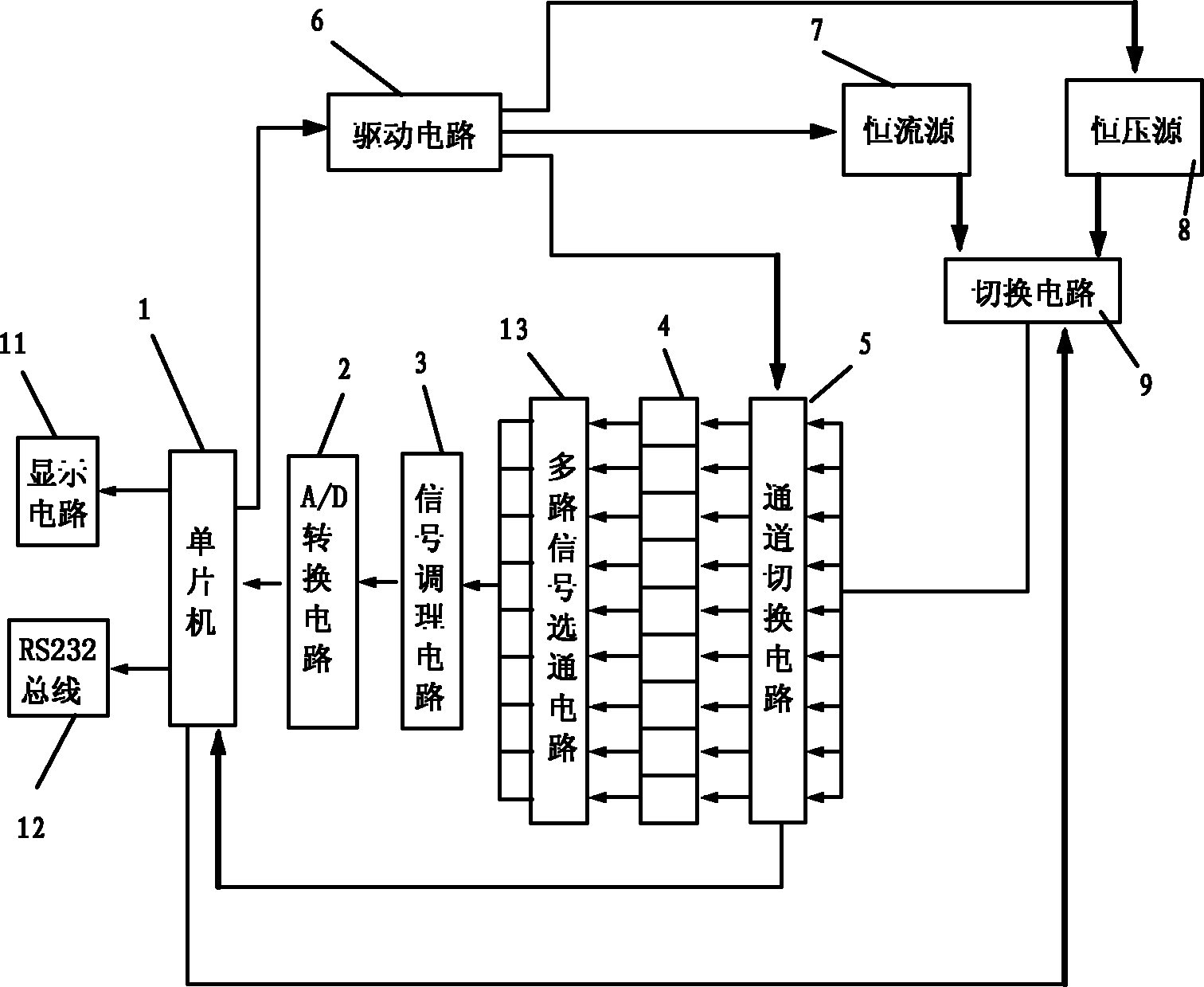

[0006] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment includes single-chip microcomputer 1, A / D conversion circuit 2, signal conditioning circuit 3, channel switching circuit 5, drive circuit 6, constant current source 7, display circuit 11 and multi-channel signal gating circuit 13, the signal of display circuit 11 The input end is connected to the display signal output end of the single-chip microcomputer 1, the data signal input end of the single-chip microcomputer 1 is connected to the data signal output end of the A / D conversion circuit 2, and the data signal input end of the A / D conversion circuit 2 is connected to the signal output of the signal conditioning circuit 3 The signal input end of the signal conditioning circuit 3 is connected to each signal output end of the multi-channel signal gating circuit 13, and each signal input end of the multi-channel signal gating circuit 13 is co...

specific Embodiment approach 2

[0007] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the channel switching circuit 5 is a relay switch array, and each relay forming the relay switch array has a switch state output terminal, and the switch state output terminal is connected to the state of the single chip microcomputer 1. on the signal input. With such setting, the resistance value signal collected by the single-chip microcomputer 1 and the detected branch can be accurately corresponded one by one to avoid confusion.

specific Embodiment approach 3

[0008] Specific implementation mode three: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes a constant voltage source 8 and a switching circuit 9, another output end of the drive circuit 6 is connected to the input end of the constant voltage source 8, and the constant current source 7 and the constant voltage source 8 The output ends are respectively connected to an input end of the switching circuit 9, the output end of the switching circuit 9 is connected to the signal input end of each channel of the channel switching circuit 5, and another control signal output end of the single-chip microcomputer 1 is connected to the controlled channel of the switching circuit 9. end. The single chip microcomputer 1 can also adjust the output values of the constant current source 7 and the constant voltage source 8 through the drive circuit 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com