Constant temperature crystal oscillator automatic current test and analysis system and method

A technology of constant temperature crystal oscillation and crystal oscillator, applied in the direction of measuring current/voltage, instruments, measuring electricity, etc., can solve the problems of unable to reproduce the real current change of the product, difficult to manage data, large data volume, etc., to improve the current Test efficiency, reduce human error, and reduce the effect of manpower use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

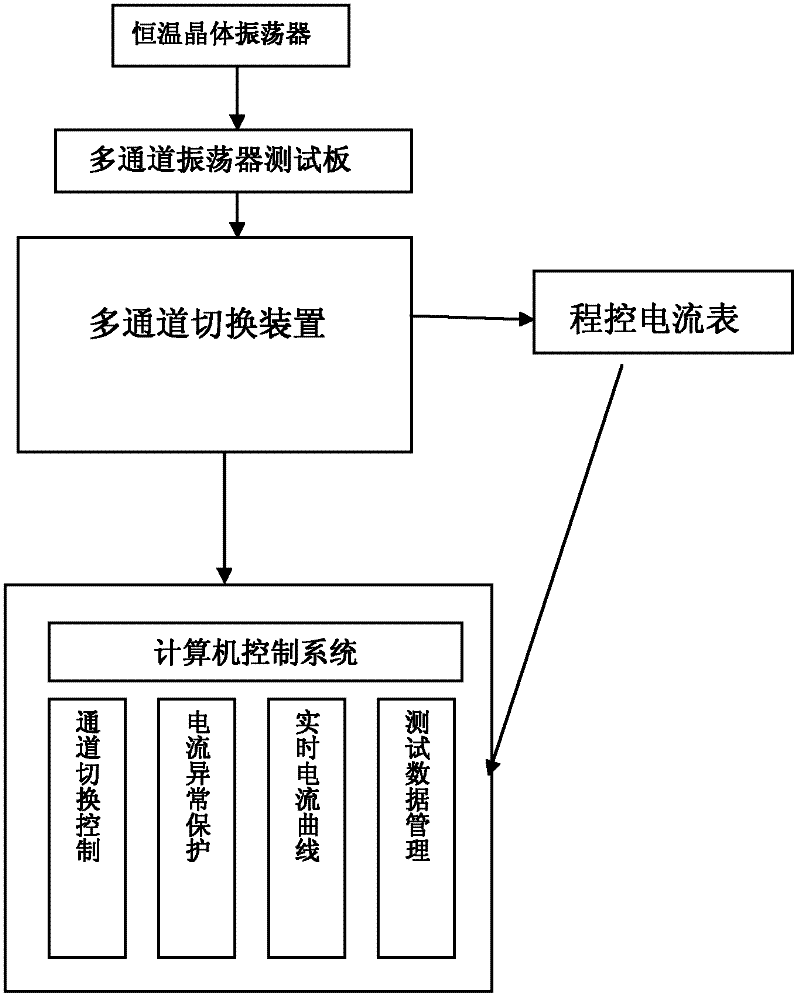

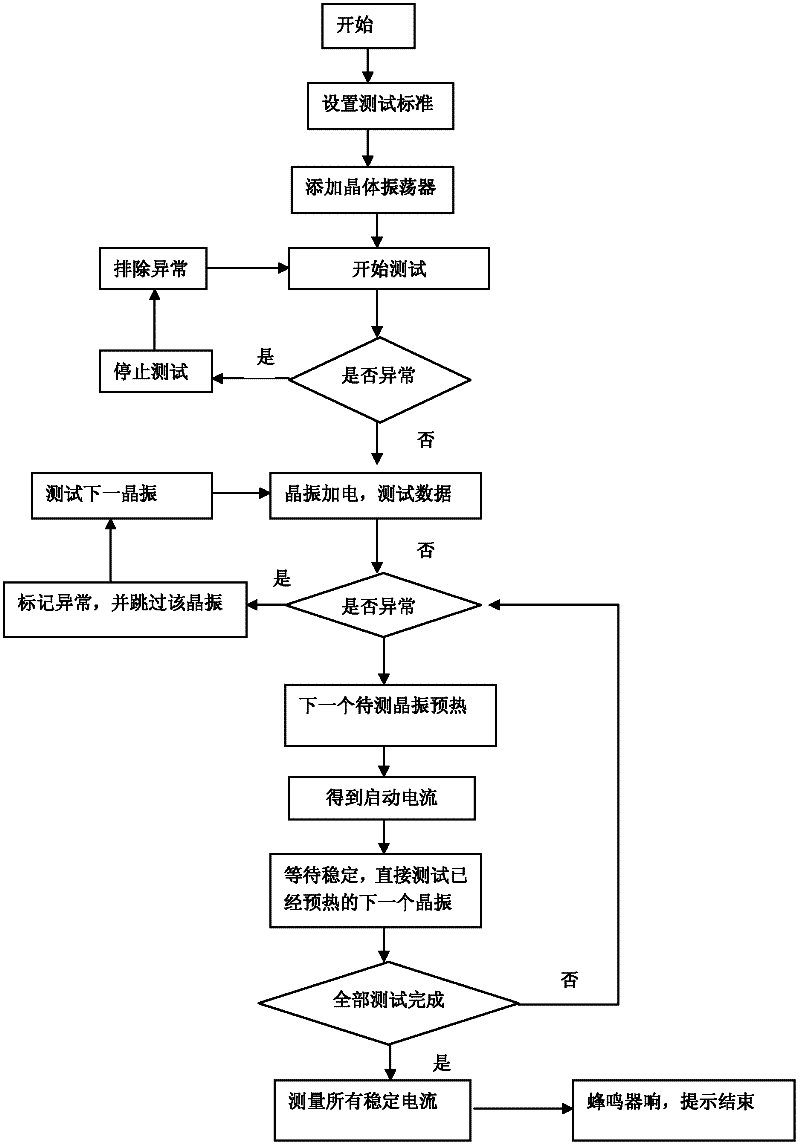

[0029] refer to figure 1 A constant temperature crystal oscillator current test system includes a multi-channel oscillator test board, a program-controlled ammeter, a multi-channel switching device, and a computer control system.

[0030] The multi-channel oscillator test board is connected with the crystal oscillator under test, and is used to load the crystal oscillator under test, and the tester inserts the crystal oscillator under test into the crystal oscillator test board.

[0031] Programmable ammeter: connected to the multi-channel switching device to measure the current value of the crystal oscillator of the corresponding channel. The ammeter is compatible with the HP3478 command set.

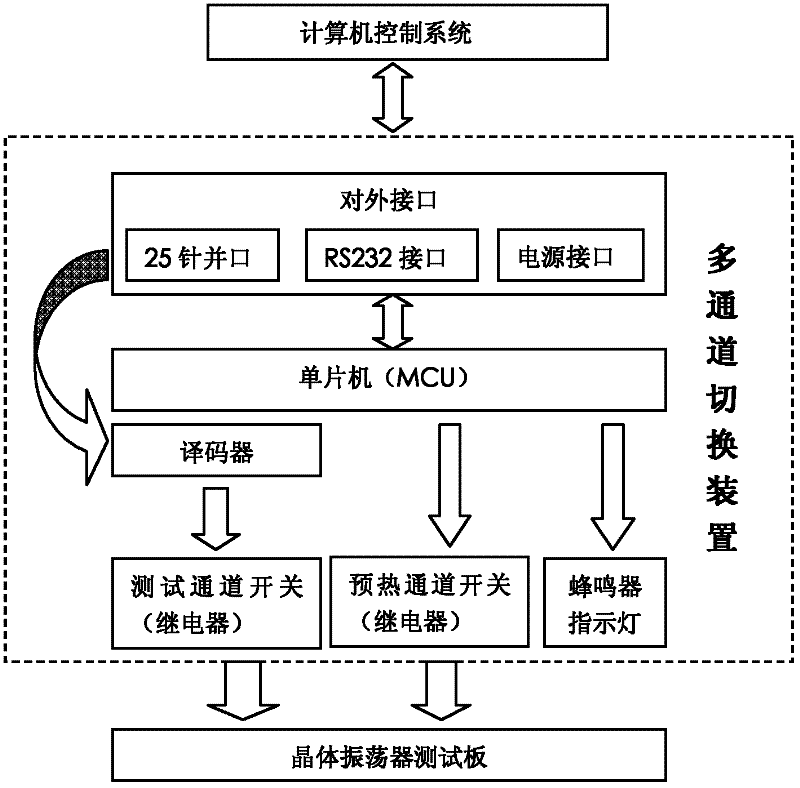

[0032] Multi-channel switching device: connected to the multi-channel oscillator test board, program-controlled ammeter, and computer control system, each channel corresponds to a tested crystal oscillator on the multi-channel oscillator test board, and is used to accept commands from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com