A Fe-based bulk permanent magnet alloy with excellent coercive force and preparation method thereof

A permanent magnet alloy, coercive force technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of low coercivity of bulk permanent magnet materials, achieve excellent coercivity, overcome the complex processing technology, The effect of expanding the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

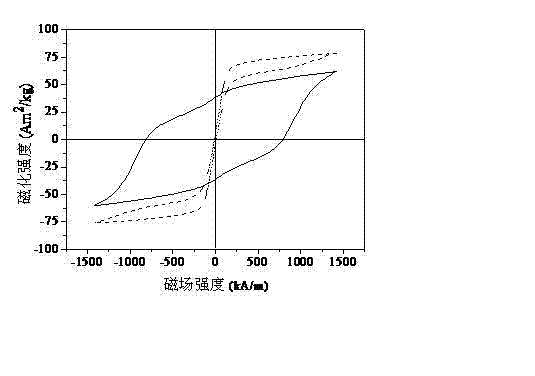

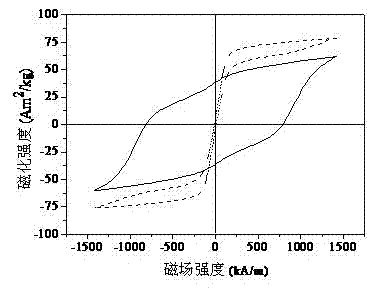

Image

Examples

Embodiment 1

[0023] The composition (atomic percentage) of the hard magnetic Fe-based bulk alloy of this embodiment is: Fe 63%, Nd 7%, Nb6, B 24%. The preparation process and steps are as follows: prepare 20 grams of industrially pure metal raw materials Fe, Nd, Nb and FeB alloy according to the Fe-based bulk alloy composition of this embodiment, and then use a vacuum non-consumable electric arc furnace to melt under the protection of argon , the melting current density is 150A / cm 2 , the alloy was repeatedly smelted 4 times to obtain a master alloy; after remelting the master alloy, it was poured by a copper mold negative pressure suction casting method to obtain a bulk amorphous alloy with a size of 1mm×10mm×80mm. Put the above bulk amorphous alloy at 690°C with a vacuum of 4×10 -3 Under the condition of Pa, vacuum annealing is carried out, and the annealing time is 20 minutes, and finally the Fe-based bulk permanent magnetic alloy with excellent coercive force of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com