Disc Milling Cutters and Cutting Elements

A technology of cutting elements and disc milling cutters, used in milling cutting inserts, milling cutters, tools of sawing machines, etc., can solve the problems of limited maximum clamping force, blade retraction, large centrifugal force, etc., to reduce harmful vibrations , high cutting thickness, improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

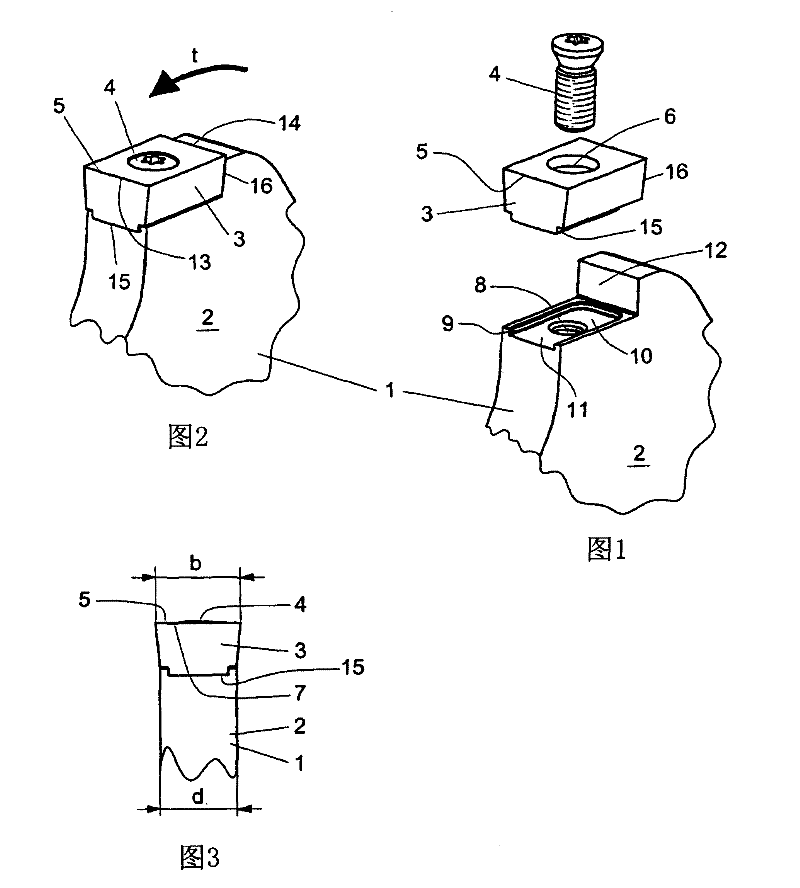

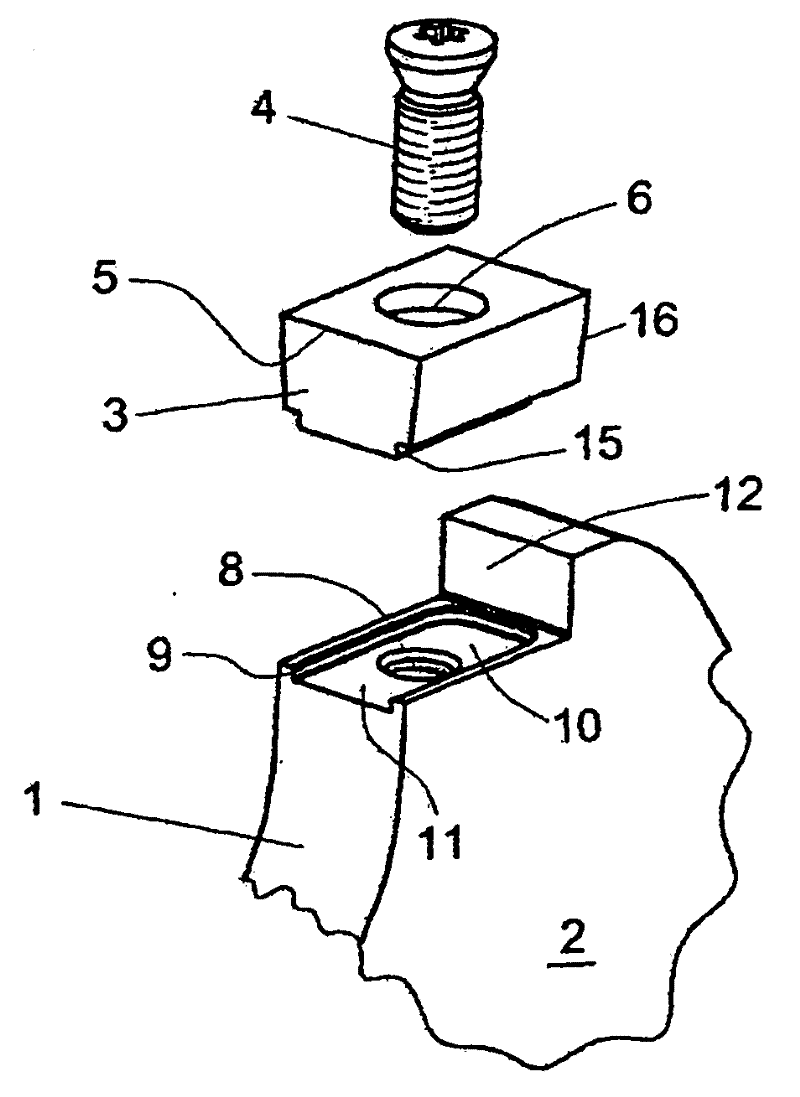

[0025] Figures 1 to 3 A preferred embodiment of the invention, shown in excerpt in , comprises a tool (1) for machining, in particular for high-feed milling and / or sawing, having a disc-shaped Base body (2) and a plurality of replaceable cutting elements (3) arranged in the edge region of the disc-shaped base body (2), just like a carbide milling cutter, and with fixing elements (4) for cutting The element (3) is fastened detachably on the edge region of the disc-shaped base body (2). The cutting element (3) has a substantially prismatic or cuboidal basic shape with at least one cutting edge (5) whose maximum width (b) exceeds the thickness (d) of the disk-shaped base body (2). In the embodiment shown in the figure, the cutting edge width (b) is about 10 mm, the disc thickness is about 8 mm, and the cutting element (3) has at least one through hole (6) for carrying the fixing member (4), wherein all The fastening means in the exemplary embodiment are formed by a fastening s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com