Manufacturing process of plug-in water dropper used for subsurface drip irrigation

A production process and underground drip irrigation technology, applied in the direction of spraying devices, spraying devices, etc., can solve the problems of affecting production and use effects, complex production process, high production cost, etc., and achieve easy maintenance and repair, good seepage irrigation effect, and manufacturing method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

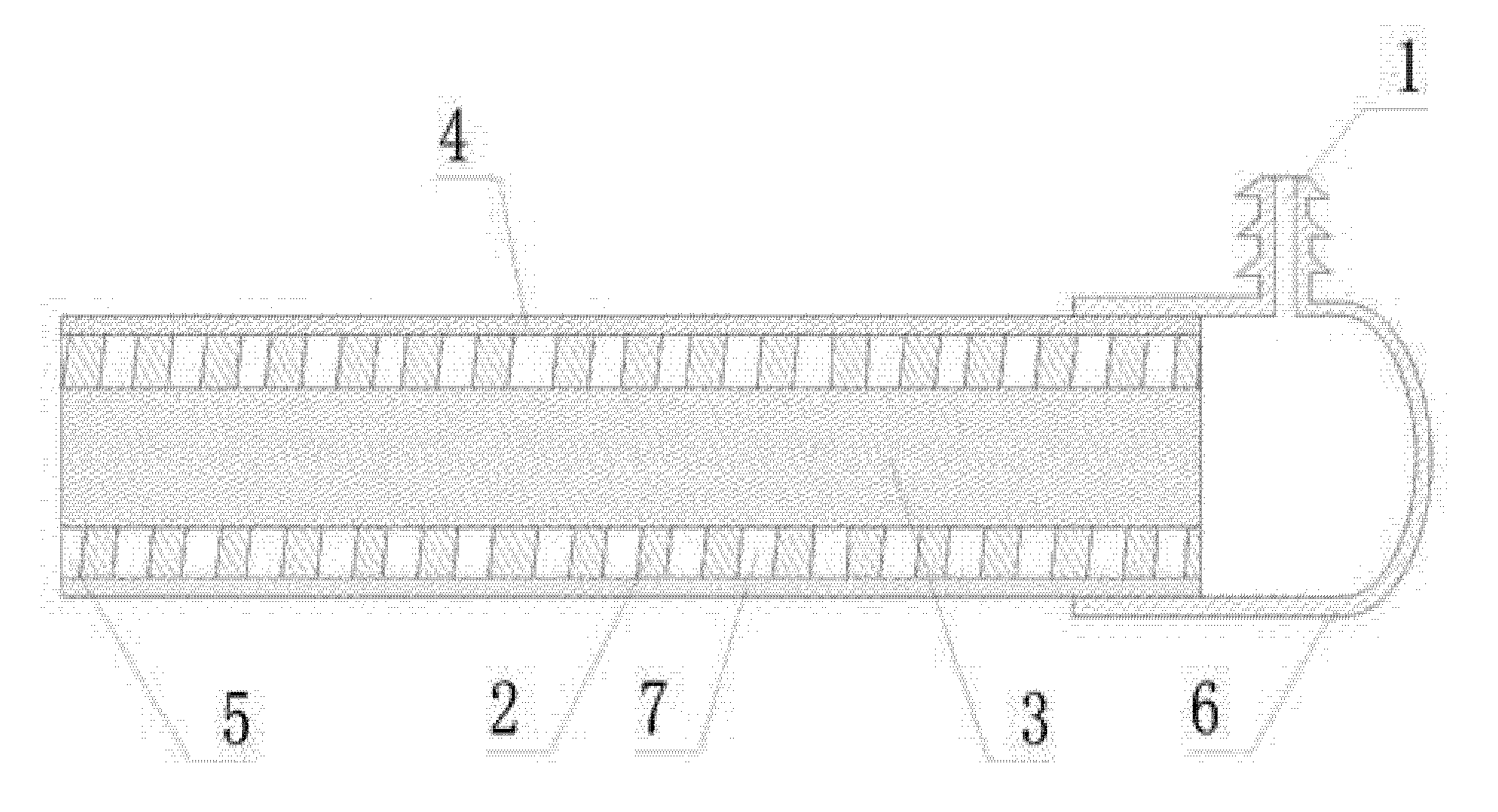

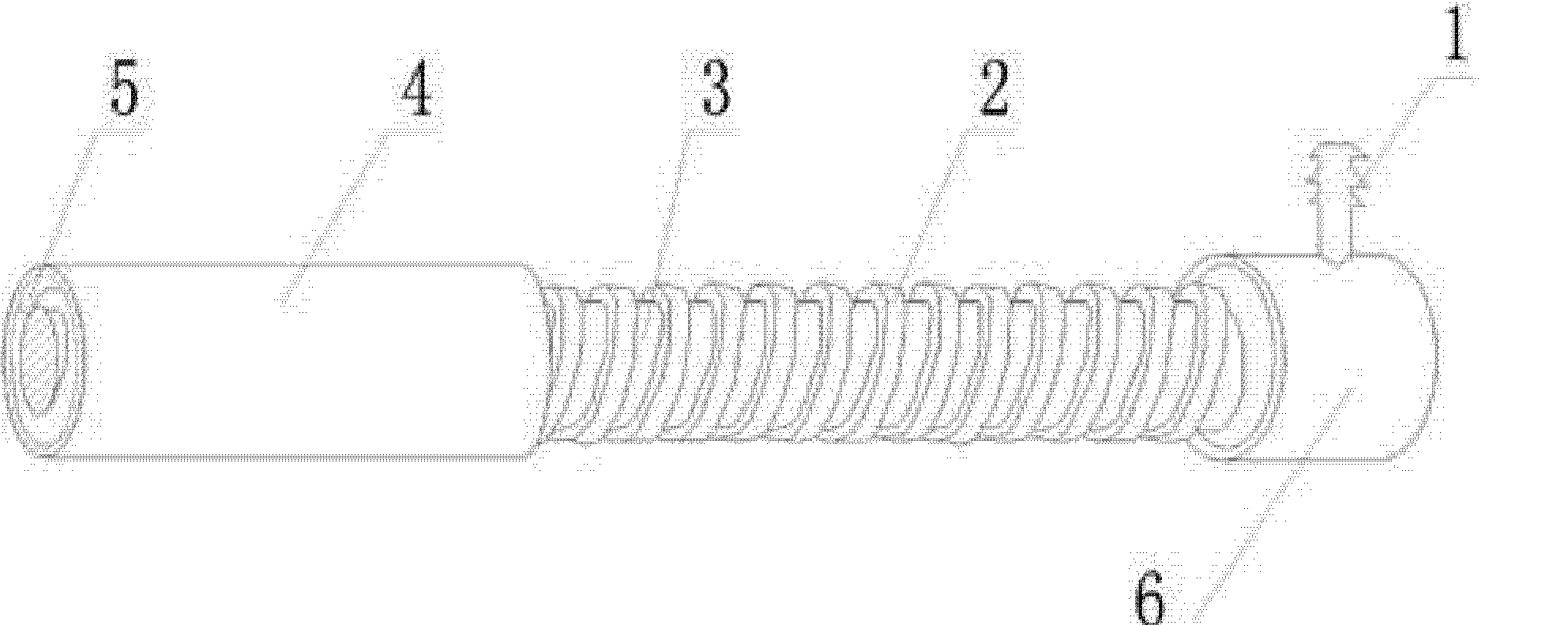

[0033] refer to figure 1 , figure 2 , Figure 4 , is a structural schematic diagram of the implementation of the present invention 1, including a plug-in dripper for underground drip irrigation disclosed by the present invention, comprising a pipe body shell 4, a water inlet connecting pipe 1, the inside of the pipe body shell 4 is a cavity, and the pipe body A solid rod 3 is provided inside the casing 4, and a spiral channel 7 is provided between the solid rod 3 and the tubular casing 4. One end of the spiral channel 7 communicates with the water inlet connecting pipe 1, and the other end opens to form a drip port 5 .

[0034] The water inlet connecting pipe 1 is connected with the pipe body shell 4 through a water inlet cap 6, and the inside of the water inlet cap 6 is a cavity, and the water inlet connecting pipe 1 communicates with the spiral water channel 7 through the cavity.

[0035] The spiral water channel 7 is constituted as follows: a spiral line 2 is provided b...

Embodiment 2

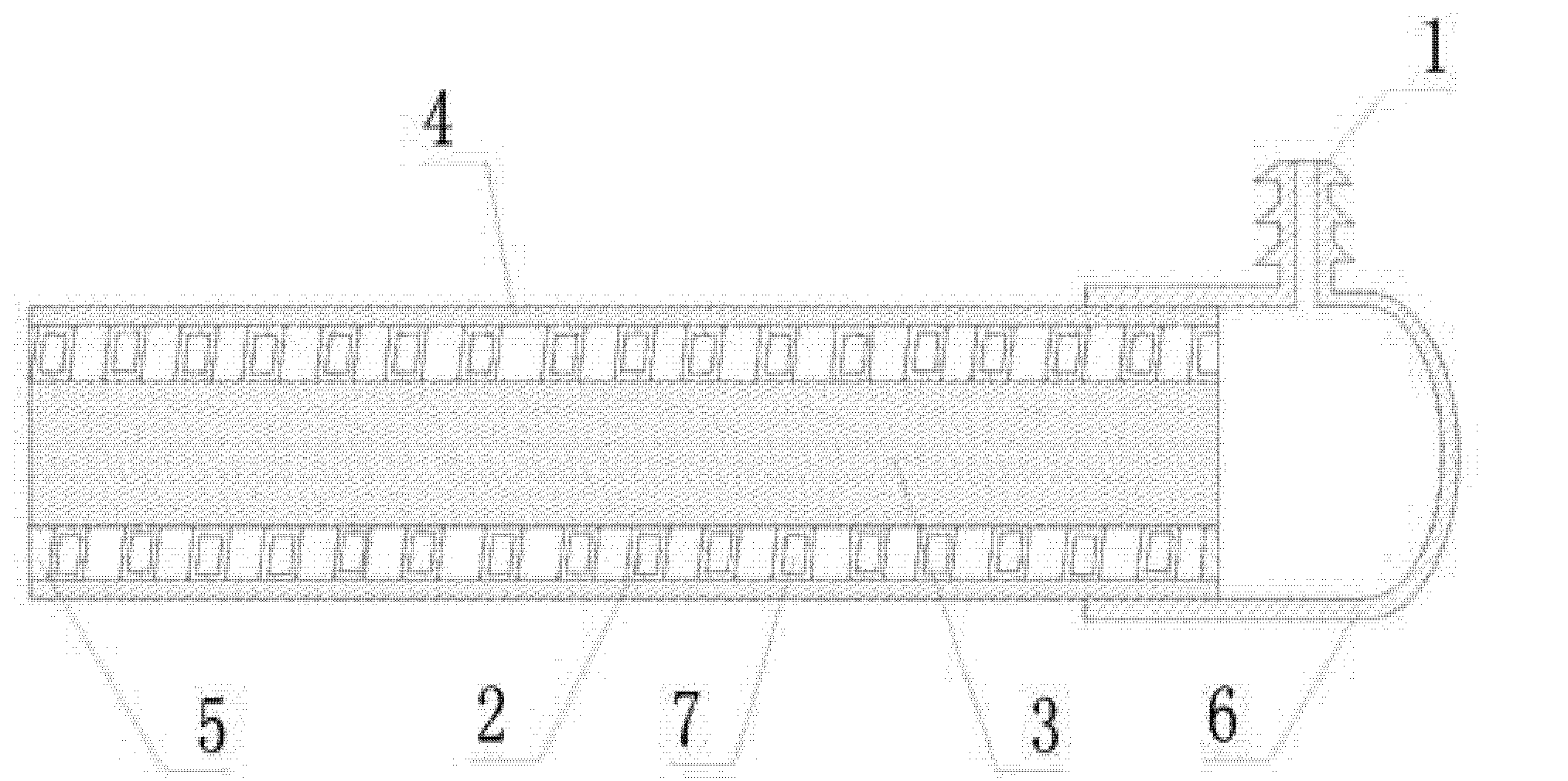

[0048] refer to image 3 , Compared with Embodiment 1, the difference of this embodiment is that the spiral line 2 is a hollow line, the cavity of the hollow line forms a spiral water channel 7, and the cross section of the spiral line 2 is circular.

Embodiment 3

[0050] Compared with Embodiment 1, the difference of this embodiment is that there is no water inlet cap 6 between the water inlet connecting pipe 1 and the pipe shell 4 , and the water inlet connecting pipe 1 directly communicates with the spiral water channel 7 . In the manufacturing process step, one end of the segmented pipe strip is sealed, a hole is drilled in the shell to communicate with the spiral water channel 7, polyvinyl chloride glue is applied, and then the water inlet connecting pipe 1 is inserted to obtain a plug-in drip finished head. The section of the spiral line 2 is triangular.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap