Continuous extrusion method and equipment for lead brass

An extrusion method and technology of extrusion equipment, applied in the field of extrusion, can solve the problems of many production processes, high cost, long production cycle, etc., and achieve the effects of avoiding processing brittleness, improving plasticity, and avoiding fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

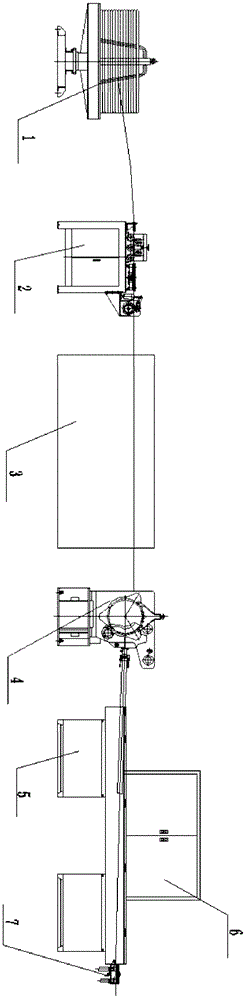

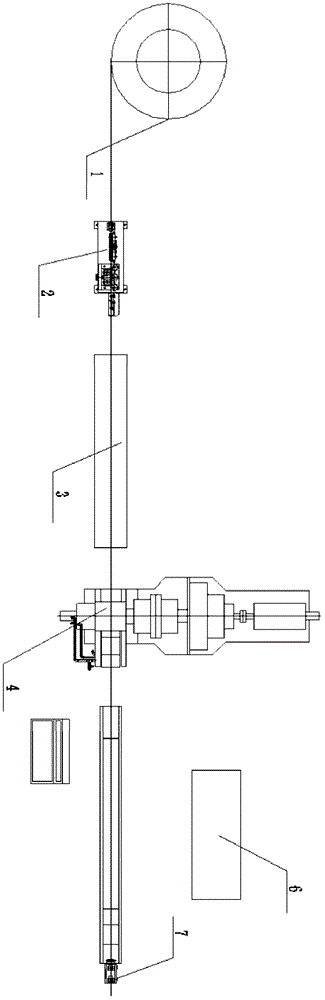

[0023] A continuous extrusion method for lead brass adopts such as Figure 1~2 The equipment shown in the figure performs continuous extrusion. First, the power supply in the main electric cabinet 6 is turned on, and the lead brass rod material is manually released from the pay-off reel 1; then the lead brass rod material is put into the straightening and feeding device 2 Send out after straightening, the feeding speed is 10m / min; the sent rod material enters the heating furnace 3 to be heated, and the temperature is heated to 500°C, and the rod material is softened; the softened rod material is sent to the extrusion wheel of the main machine 4 of the continuous extrusion machine into the cavity and mold for extrusion, and the extrusion processing temperature is 550°C; then the extruded rod material passes through the anti-oxidation protection tube and enters the cooling and anti-oxidation device 5 for cooling, and the cooling liquid contains 3% to 8 % alcohol deionized water,...

Embodiment 2

[0026] A continuous extrusion method for lead brass adopts such as Figure 1~2 The equipment shown in the figure performs continuous extrusion. First, the power supply in the main electric cabinet 6 is turned on, and the lead brass rod material is manually released from the pay-off reel 1; then the lead brass rod material is put into the straightening and feeding device 2 Send out after straightening, the feeding speed is 8m / min; the sent rod material enters the heating furnace 3 to be heated, and the temperature is heated to 620°C, and the rod material is softened; the softened rod material is sent to the extrusion wheel of the main machine 4 of the continuous extrusion machine into the cavity and mold for extrusion, and the extrusion processing temperature is 600°C; then the extruded rod material passes through the anti-oxidation protection tube and enters the cooling and anti-oxidation device 5 for cooling, and the cooling liquid contains 3% to 8 % alcohol deionized water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com