An automatic alloy circular saw blade resistance welding machine

A technology of resistance welding and automatic alloying, which is applied in the direction of resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of skin and eye damage, low precision, and electric sparks caused by conduction, so as to solve the problem of enterprise output, repeat The effect of high precision and precise dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

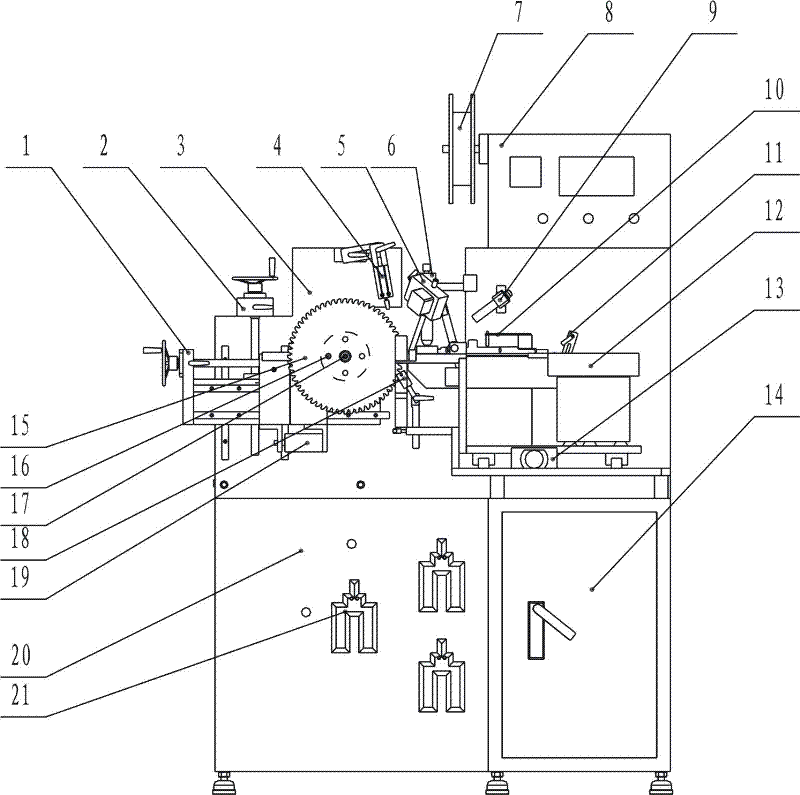

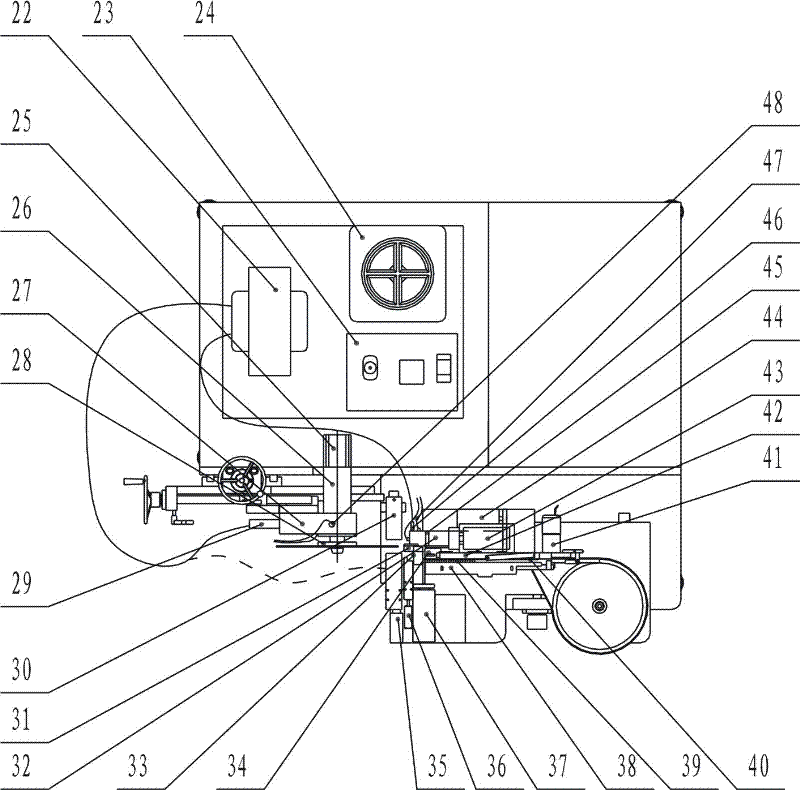

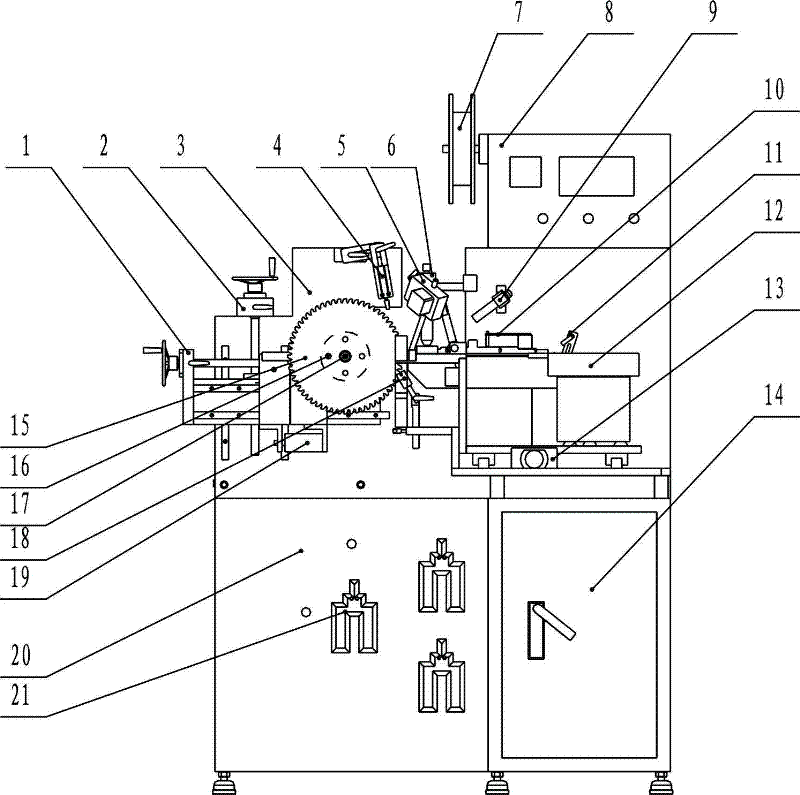

[0023] Example: such as figure 1 , 2 An automatic alloy circular saw blade resistance welding machine is mainly composed of a saw blade part, a tongue part and a control circuit part. The saw blade part includes a wallboard 3, a flange connected by a stepper motor 25 and a saw blade rotation coupling 26 The plate 28 and the alloy circular saw blade 15 fixed on the flange plate 28, the sheet pressing cylinder 4 and the saw blade pushing cylinder 19 provided on the wallboard 3 to cooperate with the alloy circular saw blade 15, cooperate with the alloy circular saw blade 15 The saw blade tooth sensor 18 and the saw blade inner positioning cylinder 30, the saw blade left and right moving device 1 and the saw blade up and down moving device 2 for adjusting the alloy circular saw blade 15 are provided on the wallboard 3, and the flange plate 28 A magnet 16 and a saw blade positioning 17 for facilitating fixing the alloy circular saw blade 15 are provided.

[0024] The tongue part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com