A method and system for removing lake silt

A sludge and lake technology, applied in dehydration/drying/concentrated sludge treatment, earth mover/excavator, construction, etc., can solve problems such as insufficient efficiency and secondary pollution, so as to improve work efficiency and reduce pollution , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

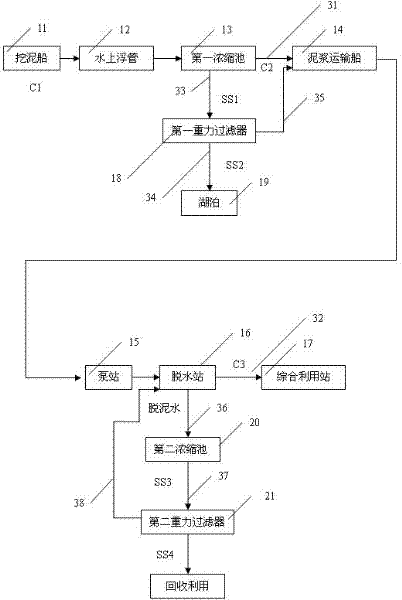

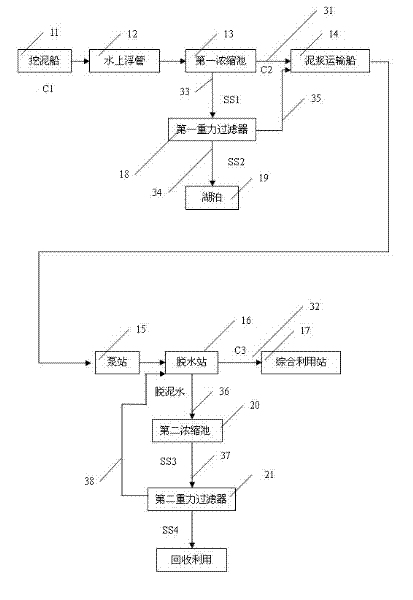

[0053] The present invention will be described in detail below in conjunction with the drawings.

[0054] figure 1 Shows the process flow of removing lake silt. The silt deposited at the bottom of the lake is pumped out by the dredger 11, the weight percentage concentration of the silt is C1=2-20%, and is sent to the first thickening tank 13 on the shore through the floating pipe 12 on the water. The first thickening tank 13 increases the sludge concentration to C2=30-35%. 30-35% of the mud is sent to the mud carrier 14 through the first passage 31. The mud carrier 14 transports the mud to the pump station 15, and the pump station 15 transports the mud to the dehydration station 16. After the mud is processed by the dehydration station 16, the concentration C3 reaches more than 60% and becomes a filter cake. The filter cake is transported through the second channel 32 to the comprehensive utilization station 17 for comprehensive utilization.

[0055] The residual water produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com