Sealing installation structure of strip gusset plate in suspended ceiling

A technology for installing structures and gussets, applied in the direction of ceilings, building components, building structures, etc., can solve problems such as affecting the quality of life, affecting human health, easily breeding bacteria, etc., to improve indoor environmental sanitation, simple structure, and practicality. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

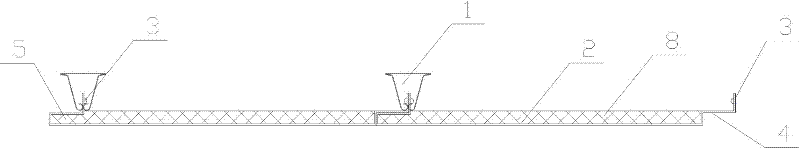

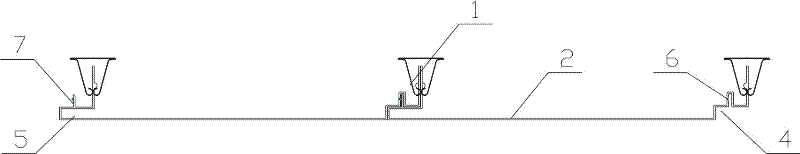

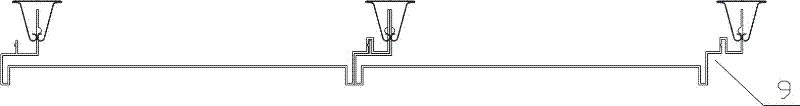

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the suspended ceiling of the present invention is mainly composed of a keel 1 and a strip-shaped gusset 2, wherein the strip-shaped gusset 2 is fastened to the triangular keel 1 at least through the connecting edges 3 on both sides. , the buckle edge 3 on one side of the strip-shaped pinch plate 2 is provided with a notch 4 inwardly along the edge of the pinch plate, while the buckle edge 3 on the other side is provided with a notch 4 to cooperate with the notch 4 outward along the edge of the pinch plate Convex block 5; Two or two type gussets 2 are respectively fastened to the triangular keel 1 through the fastening edges on both sides, and the adjacent protruding blocks 5 are embedded in the adjacent concave gaps 4 , and form two adjacent strip-shaped gussets connected by dislocation.

[0015] The recessed notch 4 on the strip-shaped pinch pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com