Finger jointed plate floor

A finger-jointed board and floor technology, which is applied in the direction of floors, buildings, and building structures, can solve problems such as low static bending strength and elastic modulus, inability to meet deformation resistance, and inability to be used as floor substrates to achieve structural Reasonable and stable, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

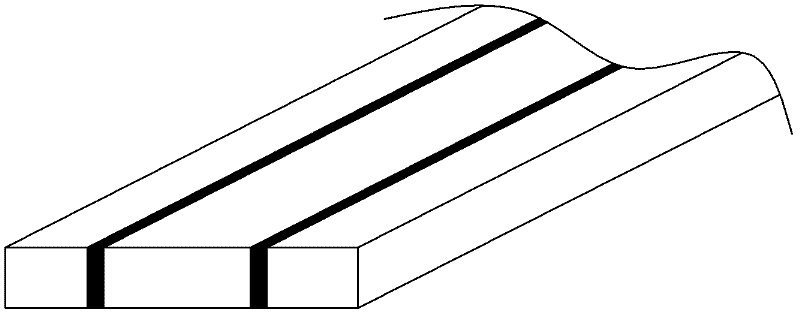

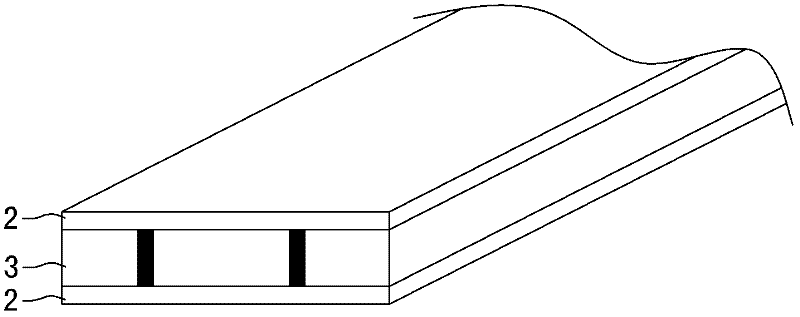

[0028] see Figure 1~5 As shown, a finger-jointed board floor comprises, from top to bottom, a decorative wood veneer 1, a wood veneer 2, a finger-joint board 3, a wood veneer and a decorative wood veneer,

[0029] The fiber length direction of the wood veneer is perpendicular to the length direction of the finger-jointed board, and the fiber length direction of the decorative wood veneer is perpendicular to the fiber length direction of the adjacent wood veneer;

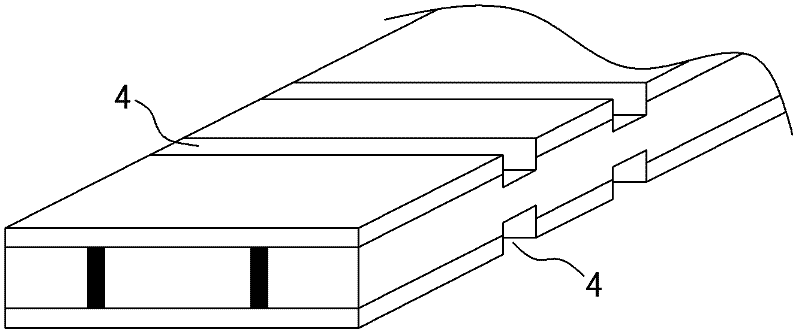

[0030] The wood veneer is provided with at least 2 through slots 4 along the direction perpendicular to its fiber length direction, and the slots cut the wood veneer and go deep into the finger-jointed board; the slots go deep into the The depth of the finger joint plate accounts for 30% of the total thickness of the finger joint plate;

[0031] A molding strip 5 is arranged in the slot, and the surface of the molding strip is flush with the surface of the wood veneer.

[0032] The upper and lower wooden veneers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com