A hydraulic shearing sampling drilling tool

A cutting-type drilling tool technology, which is applied in the fields of geology, petroleum, and ocean exploration, can solve problems such as sampling difficulties, sample disturbance, and drill pipe bending, and achieve the goal of improving sample collection rate, speed of disassembly and assembly, and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

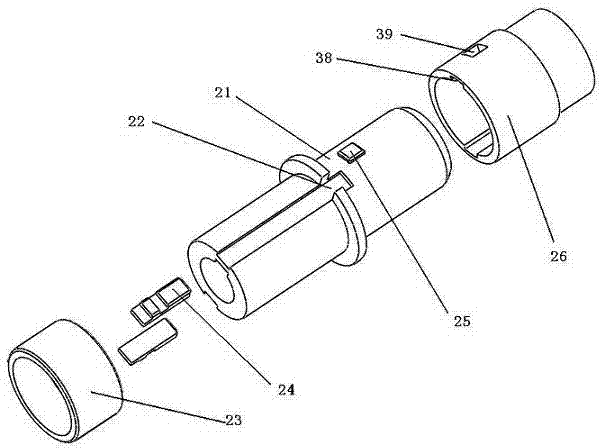

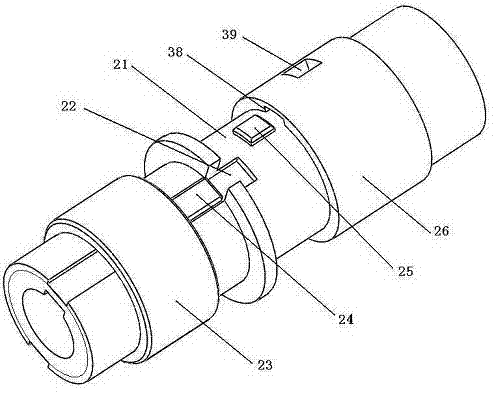

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

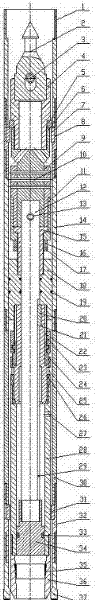

[0013] figure 1 The hydraulic shearing sampling drilling tool shown in the present invention is composed of a sampling outer pipe assembly and a sampling inner pipe assembly arranged in the sampling outer pipe assembly.

[0014] Such as figure 1 As shown, the sampling outer pipe assembly of the present invention includes an upper joint 1, an upper centralizer 8, an outer pipe joint 14, a sampling outer pipe 30, a lower centralizer 32 and a drill bit 37 arranged sequentially from top to bottom. All are tubular, and adjacent pieces are connected to each other by threads. The upper centralizer 8 and the inner wall of the lower centralizer 32 each have a step support surface, a seat ring 7 is arranged on the step support surface in the upper centralizer 8, and a centralizing ring 31 is arranged on the step support surface in the lower centralizer 32 for positioning the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com