Axial flow impeller with composite hinged blade and hub

An axial flow impeller and composite hinge technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., to achieve the effects of weight reduction, production cost reduction and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

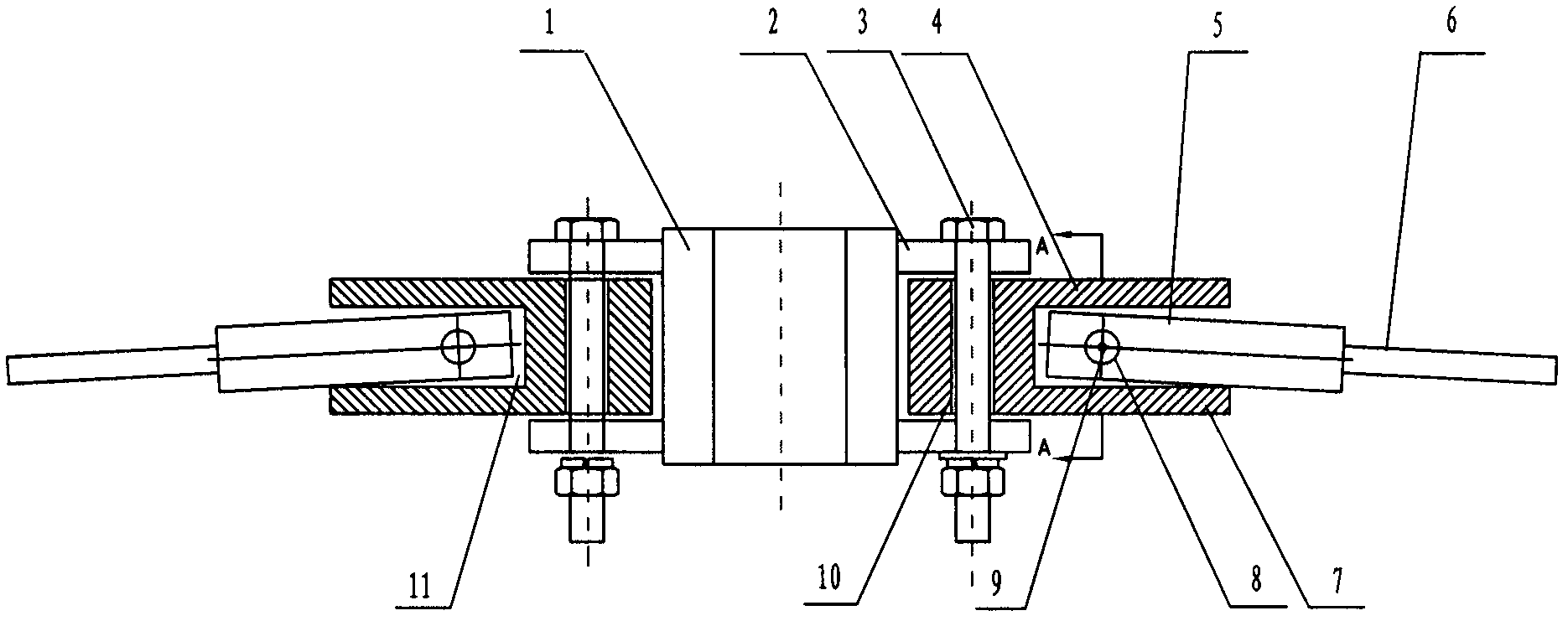

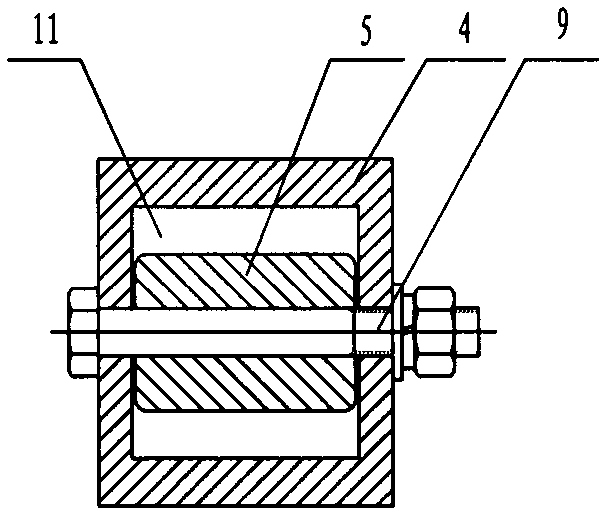

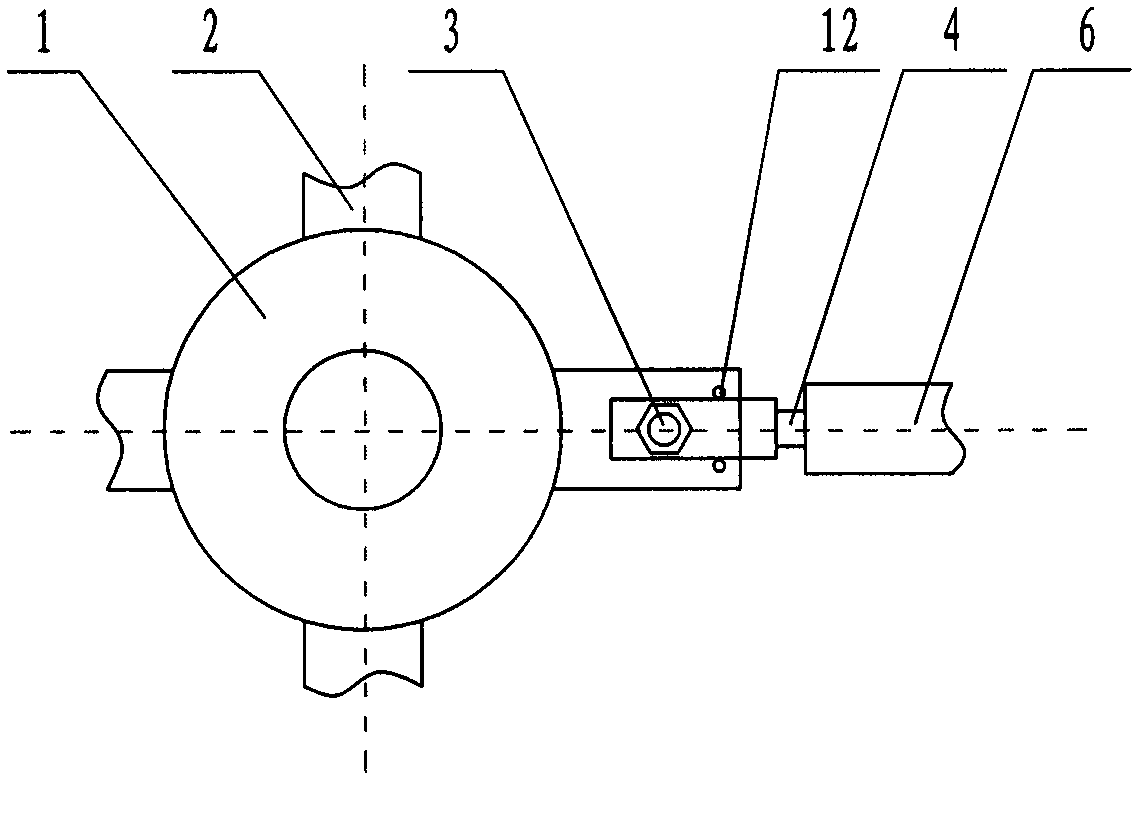

[0014] Embodiment 1: The rotating shaft of the impeller is vertical to the ground, and the blades discharge air upward or downward.

[0015] Impeller diameter D=3m, hub diameter d=0.3m, power N=7.5kW, speed n=260r / min, blade mass M=8kg, number of blades Z=4, total pressure P=115Pa.

[0016] Calculated: angular velocity ω=n×π / 30=27.2rad / s, blade center of gravity radius R=(D+d) / 4=0.825m, blade center of mass position L1=0.675m, blade aerodynamic center position L2=1.01m.

[0017] Gravity W=mg=78.4N,

[0018] Aerodynamic force F2=(π×D 2 ×P / 4) / Z=203N,

[0019] Centrifugal force F3=M×R×ω 2 =4883N,

[0020] Air resistance F4=9551N / (n×L2×Z)=68.2N

[0021] When the wind is discharged upwards, the downward swing angle of the blade is α=arc tg(W+1.5F2) / F3=4.5°, and the left and right swing angle of the blade is β=arc tg(1.5F4 / F3)=1.2°.

[0022] The upward swing angle of the downward exhaust air blade is α=2.6°, and the left and right swing angle of the blade is β=1.2°.

Embodiment 2

[0023] Embodiment 2: The rotating shaft of the impeller is vertical to the ground, and the blades discharge wind upward or downward.

[0024] D=9.2m, d=1.5m, N=200KW, n=127r / min, M=65kg, Z=10, P=175Pa

[0025] Calculated: ω=13.3rad / s, R=2.675m, L1=1.925, L2=2.888.

[0026] Calculated by the formula in Example 1: W=637N, F2=1163N, F3=30757N, F4=521N.

[0027] When the wind is discharged upwards, the downward swing angle of the blade is α=4.4°, and the left and right swing angle β=1.5°;

[0028] When the air is exhausted downward, the angle α=2.1° that the blade swings upwards=2.1°, and the angle β=1.5° that swings left and right.

Embodiment 3

[0029] Embodiment 3, the rotating shaft of the impeller is parallel to the ground, and the air is exhausted horizontally.

[0030] In the case of horizontal exhaust, the α angle of the up and down swing is smaller than the upward exhaust and greater than the downward exhaust, so there is no need to calculate it, and the β angle of the left and right swing is sufficient. However, when the β angle rotates 360°, the β value is different at different positions, and now only the maximum and minimum values are calculated.

[0031] β=arc tg{9551N / [(n×L1×Z)±W] / F3}.

[0032] The impeller D=3m, βmax=2.1°, βmin=0.28°.

[0033] The impeller D=9.2m, βmax=2.6°, βmin=0.26°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com