Control method of hydraulic system and control method of concrete pump truck

A technology of a concrete pump truck and a control method, which is applied in the directions of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem of reduced engine load rate, poor energy saving effect, insufficient pumping capacity, etc. problems, to achieve the effect of increasing the load rate and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

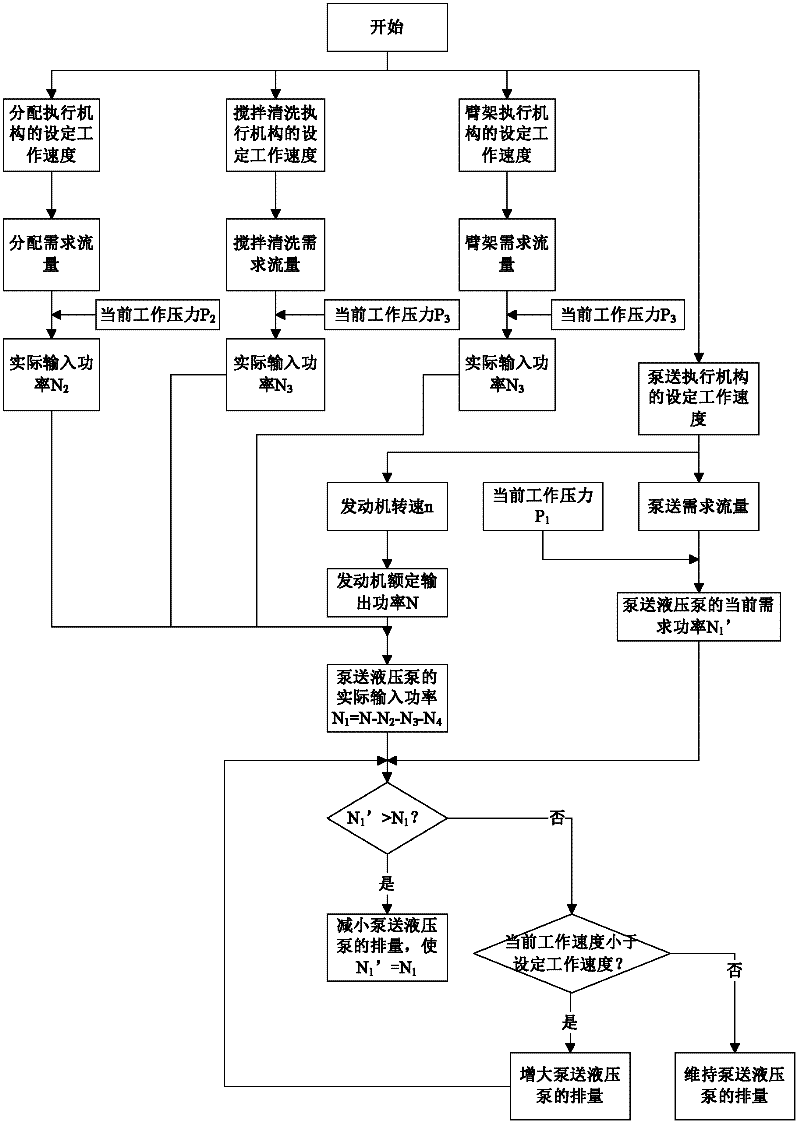

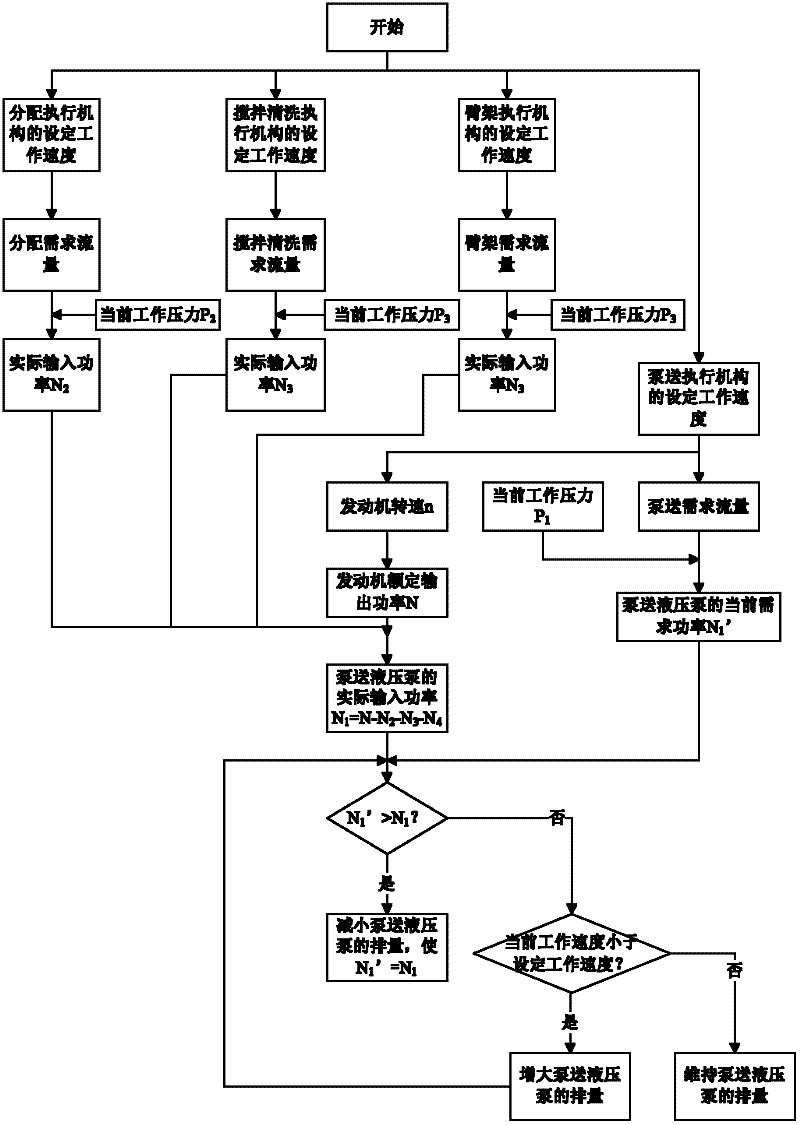

[0032] Terminology Explanation

[0033] The set working speed of the actuator: the expected working speed of the actuator set by the staff for a certain working environment and work requirements;

[0034] The current demand power of the variable pump N 1 ’: Determined according to the set working speed and current working pressure of the variable pump;

[0035] The actual input power of the variable pump N 1 : The rated output power N of the prime mover (such as an engine) minus the actual input power N of other hydraulic pumps 2 , N 3 ..., ie N 1 =(N-N 2 -N 3 ...).

[0036] The working principle and working process of the present invention will be described in detail below.

[0037] The present invention firstly discloses a control method of a hydraulic system, the hydraulic system includes a plurality of hydraulic pumps driven by a prime mover, and each hydraulic pump drives a corresponding actuator, and a first variable pump is included in the plurality of hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com